Production process of high-purity ethyl tert-butyl ether

A production process, the technology of tert-butyl ether, applied in the field of synthesis of ether compounds, can solve the problems of increasing the rectification load, the influence of ETBE purity, and the limitation of reaction balance, and achieve the goal of prolonging the service life, simple and flexible operation, and restoring adsorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

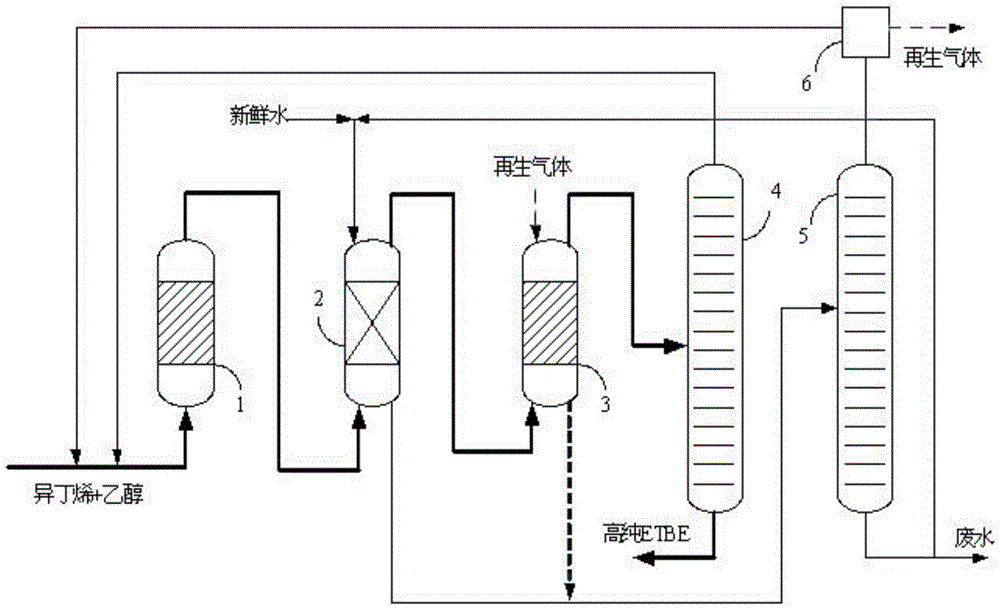

[0032] combine figure 1 , the production technique of the present embodiment high-purity ethyl tert-butyl ether comprises the following steps:

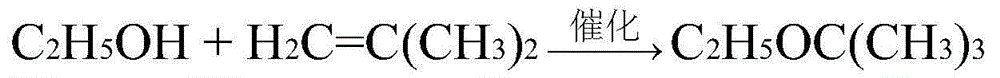

[0033] Step 1. The mixture formed by mixing ethanol and isobutylene in a molar ratio of 1.05:1 is sent into the 2-stage fixed-bed etherification reactor 1 equipped with a catalyst, at a temperature of 70° C., a pressure of 1.2 MPa, and a liquid space velocity of 2.0h -1 Carry out etherification reaction under the condition of condition, obtain crude product; Described catalyzer is preferably macroporous strongly acidic styrenic cation-exchange resin, and this ion-exchange resin is existing commercially available easily;

[0034] Step 2, sending the crude product described in step 1 into the washing tower 2 for washing and extraction treatment to obtain an aqueous phase solution and an oil phase solution; during the washing and extraction treatment process, the crude product is in reverse contact with washing water;

[0035] After te...

Embodiment 2

[0043] combine figure 1 , the production technique of the present embodiment high-purity ethyl tert-butyl ether comprises the following steps:

[0044] Step 1. The mixture formed by mixing ethanol and isobutylene in a molar ratio of 1.15:1 is sent into a three-stage fixed-bed etherification reactor 1 equipped with a catalyst, at a temperature of 60° C., a pressure of 1.2 MPa, and a liquid space velocity of 3.0h -1 Carry out etherification reaction under the condition of condition, obtain crude product; Described catalyzer is preferably macroporous strongly acidic styrenic cation-exchange resin, and this ion-exchange resin is existing commercially available easily;

[0045] Step 2, sending the crude product described in step 1 into the washing tower 2 for washing and extraction treatment to obtain an aqueous phase solution and an oil phase solution; during the washing and extraction treatment process, the crude product is in reverse contact with washing water;

[0046] After ...

Embodiment 3

[0054] combine figure 1 , the production technique of the present embodiment high-purity ethyl tert-butyl ether comprises the following steps:

[0055] Step 1. The mixture formed by mixing ethanol and isobutylene in a molar ratio of 1.4:1 is sent into the 2-stage fixed-bed etherification reactor 1 equipped with a catalyst, at a temperature of 65° C., a pressure of 2.0 MPa, and a liquid space velocity of 1.0h -1 Carry out etherification reaction under the condition of condition, obtain crude product; Described catalyzer is preferably macroporous strongly acidic styrenic cation-exchange resin, and this ion-exchange resin is existing commercially available easily;

[0056] Step 2, sending the crude product described in step 1 into the washing tower 2 for washing and extraction treatment to obtain an aqueous phase solution and an oil phase solution; during the washing and extraction treatment process, the crude product is in reverse contact with washing water;

[0057] After tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com