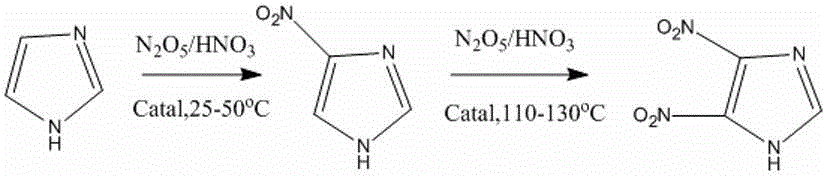

Preparation method of 4-nitroimidazole and 4,5-dimetridazloe

A technology of dinitroimidazole and nitroimidazole is applied in chemical recycling, organic chemistry and other directions to achieve the effect of improving synthesis efficiency and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] Example 1: A kind of synthetic method of 4-nitroimidazole

[0022] Step 1. In a polytetrafluoroethylene-lined stainless steel reactor, the N 2 o 5 Dissolves in fuming nitric acid to form N 2 o 5 / fuming nitric acid saturated solution, followed by adding mesoporous SO 4 2- / ZrO 2 -CeO 2 The superacid catalyst and imidazole are stirred and mixed at room temperature to form a slurry reaction liquid, wherein the molar ratio of imidazole to fuming nitric acid is 1 / 2, and the amount of catalyst is 10% of the mass of fuming nitric acid;

[0023] Step 2. Seal the reaction kettle tightly, raise the temperature to 25°C, and stir until the reaction is complete;

[0024] Step 3, cooling and diluting the reaction solution in step 2 in ice water, standing, layering, and filtering to recover the catalyst, extracting and filtering the reaction solution with dichloromethane, taking the organic phase, rotary evaporation, and drying to obtain 4-nitroimidazole , the yield is 72%, ...

example 2

[0025] Example 2: A kind of synthetic method of 4-nitroimidazole

[0026] Step 1. In a polytetrafluoroethylene-lined stainless steel reactor, the N 2 o 5 Dissolves in fuming nitric acid to form N 2 o 5 / fuming nitric acid saturated solution, followed by adding mesoporous SO 4 2- / ZrO 2 -CeO 2 The superacid catalyst and imidazole are stirred and mixed at room temperature to form a slurry reaction liquid, wherein the molar ratio of imidazole to fuming nitric acid is 1 / 3, and the amount of catalyst used is 10% of the mass of fuming nitric acid.

[0027] Step 2. Seal the reaction kettle tightly, raise the temperature to 30°C, and stir until the reaction is complete;

[0028] Step 3, cooling and diluting the reaction solution in step 2 in ice water, standing, layering, and filtering to recover the catalyst, extracting and filtering the reaction solution with dichloromethane, taking the organic phase, rotary evaporation, and drying to obtain 4-nitroimidazole , the yield is ...

example 3

[0029] Example 3: A kind of synthetic method of 4-nitroimidazole

[0030] Step 1. In a polytetrafluoroethylene-lined stainless steel reactor, the N 2 o 5 Dissolves in fuming nitric acid to form N 2 o 5 / fuming nitric acid saturated solution, followed by adding mesoporous SO 4 2- / ZrO 2 -CeO 2 The superacid catalyst and imidazole are stirred and mixed at room temperature to form a slurry reaction liquid, wherein the molar ratio of imidazole to fuming nitric acid is 1 / 4, and the amount of catalyst used is 15% of the mass of fuming nitric acid.

[0031] Step 2. Seal the reactor, heat up to 50°C, and stir until the reaction is complete;

[0032] Step 3, cooling and diluting the reaction solution in step 2 in ice water, standing, layering, and filtering to recover the catalyst, extracting and filtering the reaction solution with dichloromethane, taking the organic phase, rotary evaporation, and drying to obtain 4-nitroimidazole , the yield is 90%, the purity is 95%, the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com