Environment-friendly compound paint

A technology of environmentally friendly paint and nano-calcium carbonate, which is applied in the field of paint and coatings, can solve problems affecting consumers' health, achieve cost reduction, reduce production costs, and achieve good quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

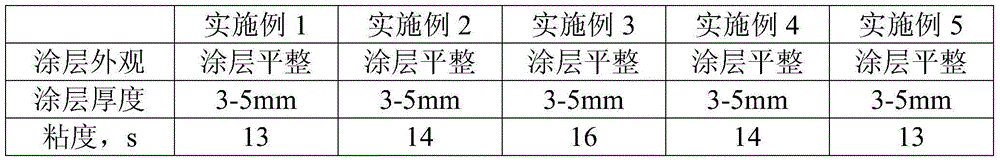

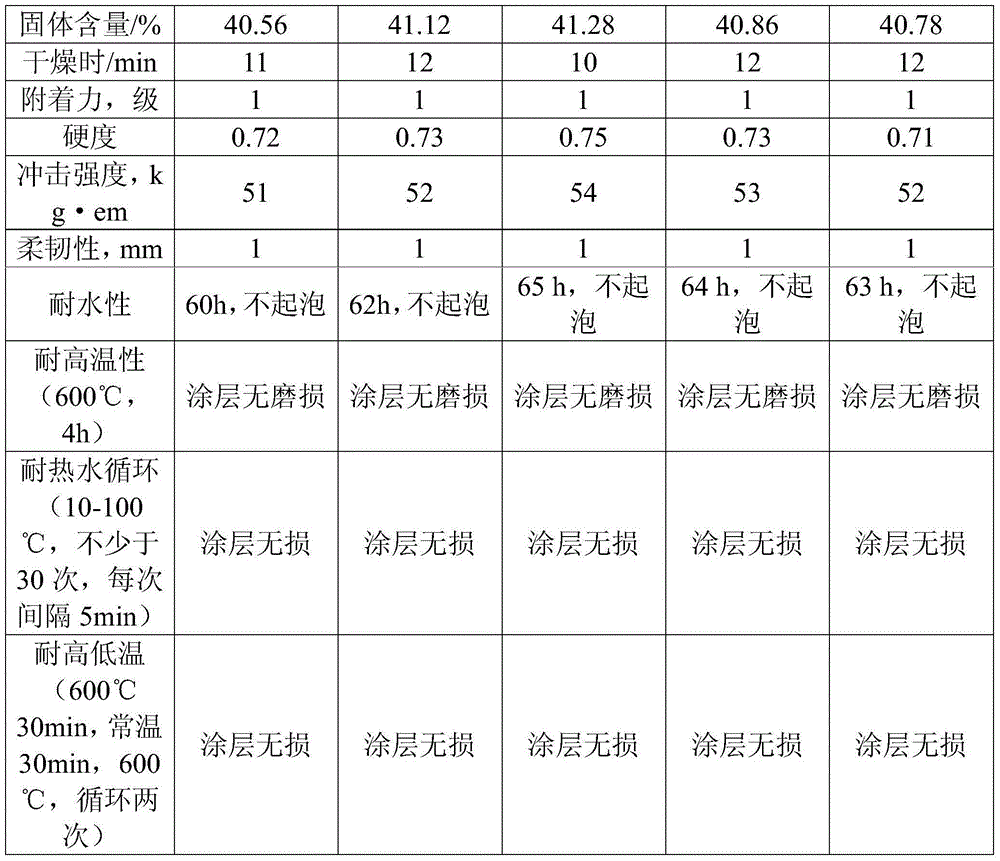

Examples

Embodiment 1

[0018] A composite environmental protection paint, the composition of the mass parts of the composite environmental protection paint is as follows: 40 parts of thermoplastic acrylic resin, 8 parts of cellulose acetate, 6 parts of nano-calcium carbonate powder, 5 parts of nano-zinc oxide powder, 36 parts of limonene, 6 parts of polyol 8 parts, 8 parts of phthalic anhydride, 0.8 parts of mica coated with titanium dioxide, and 0.8 parts of coupling agent.

[0019] Wherein, the nano-calcium carbonate powder is activated nano-calcium carbonate powder.

[0020] Wherein, the activated nano-calcium carbonate powder is prepared by the following method: adding nano-calcium carbonate to the sodium fatty acid solution, introducing carbon dioxide to adjust the pH of the solution to 5-6, controlling the activation temperature to be 90-98°C, and the activation time to be After 20 minutes, filter and dry the obtained solid matter to obtain the activated nano-calcium carbonate powder. The amou...

Embodiment 2

[0023] A kind of composite environmental protection paint, the mass parts composition of described composite environmental protection paint is as follows: 45 parts of thermoplastic acrylic resins, 9 parts of cellulose acetate, 7 parts of nano-calcium carbonate powders, 6 parts of nano-zinc oxide powders, 40 parts of limonene, 7 parts of polyols parts, 9 parts of phthalic anhydride, 1.0 parts of mica coated with titanium dioxide, and 1.2 parts of coupling agent.

[0024] Wherein, the nano-calcium carbonate powder is activated nano-calcium carbonate powder.

[0025] Wherein, the activated nano-calcium carbonate powder is prepared by the following method: adding nano-calcium carbonate to the sodium fatty acid solution, introducing carbon dioxide to adjust the pH of the solution to 5-6, controlling the activation temperature to be 98-100° C., and the activation time to be 30min, filter, and dry the obtained solid matter to obtain the activated nano-calcium carbonate powder, and th...

Embodiment 3

[0028] A kind of composite environmental protection paint, the mass parts composition of described composite environmental protection paint is as follows: 50 parts of thermoplastic acrylic resins, 10 parts of cellulose acetate, 8 parts of nano-calcium carbonate powders, 8 parts of nano-zinc oxide powders, 40 parts of limonene, 9 parts of polyols parts, 12 parts of phthalic anhydride, 1.6 parts of mica coated with titanium dioxide, and 1.6 parts of coupling agent.

[0029] Wherein, the nano-calcium carbonate powder is activated nano-calcium carbonate powder.

[0030] Wherein, the activated nano-calcium carbonate powder is prepared by the following method: adding nano-calcium carbonate to the sodium fatty acid solution, introducing carbon dioxide to adjust the pH of the solution to 5-6, controlling the activation temperature to be 98-100° C., and the activation time to be After 30 minutes, filter and dry the obtained solid matter to obtain the activated nano-calcium carbonate po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com