Production system of biomass moulding fuel

A molding fuel and production system technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of lack of raw material screening, impurity removal, and finished product screening, so as to reduce the incidence of occupational diseases of workers, have good applicability, and reduce safety hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

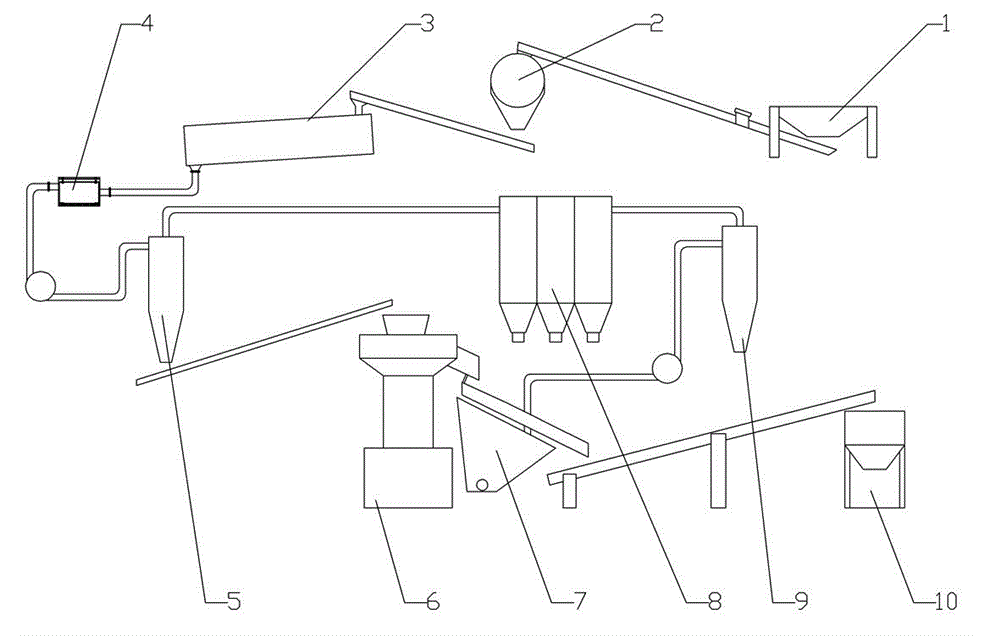

[0016] The specific implementation manner of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] Reference signs: feeding hopper 1; screening device 2; drying device 3; stone remover 4; primary cyclone separator 5; forming device 6; screening device 7; bag filter 8; secondary cyclone separator; finished product cooling device 10.

[0018] Such as figure 1 As shown, the raw materials are: corn stalks, wheat straw, straw, peanut husks, corncobs, cotton stalks, soybean stalks, rice husks, weeds, branches, leaves, sawdust, bark, medicinal residues, tea seed husks, distiller’s grains, fungi lignin-rich agricultural and industrial wastes. Mix one or more kinds of raw materials and send them into the feed hopper 1 after being crushed. The outlet of the feed hopper 1 is equipped with a conveyor belt, and the conveyor belt is equipped with an iron removal device; the raw materials after iron removal are conveyed The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com