Single-stroke air pressure engine, implementation method and application of engine

An engine and single-stroke technology, which is applied in the direction of atmospheric engines, engine starting, engine components, etc., can solve problems such as inability to pump air, loss of practicability, and complicated problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

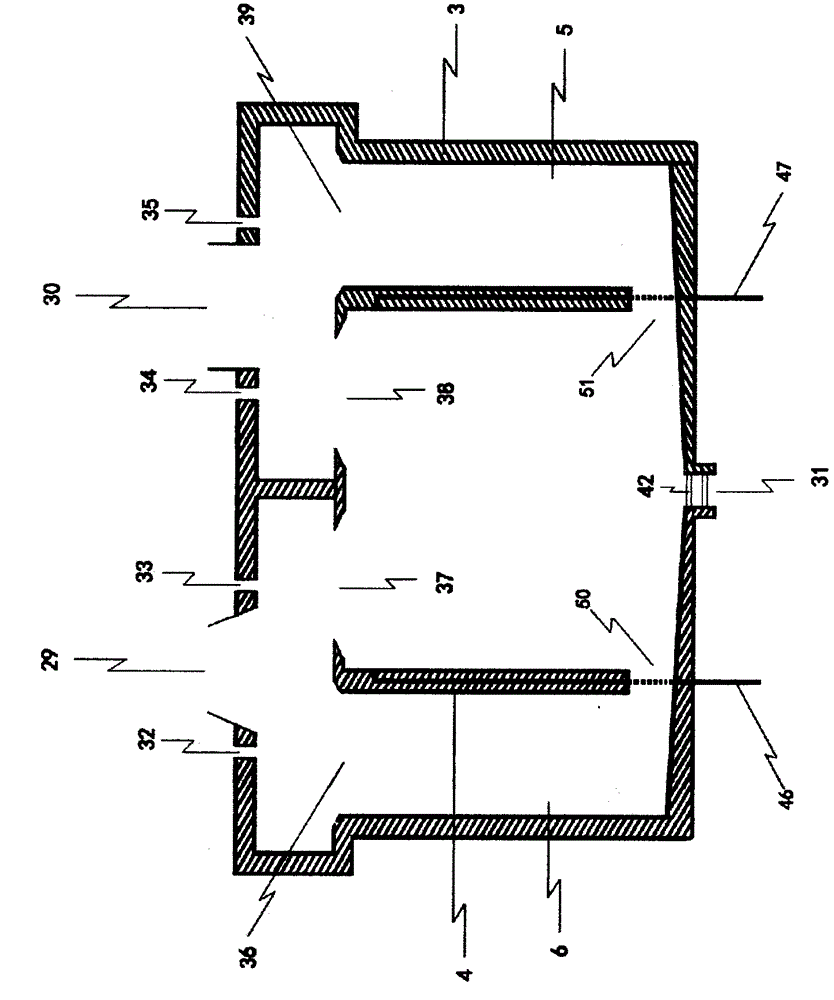

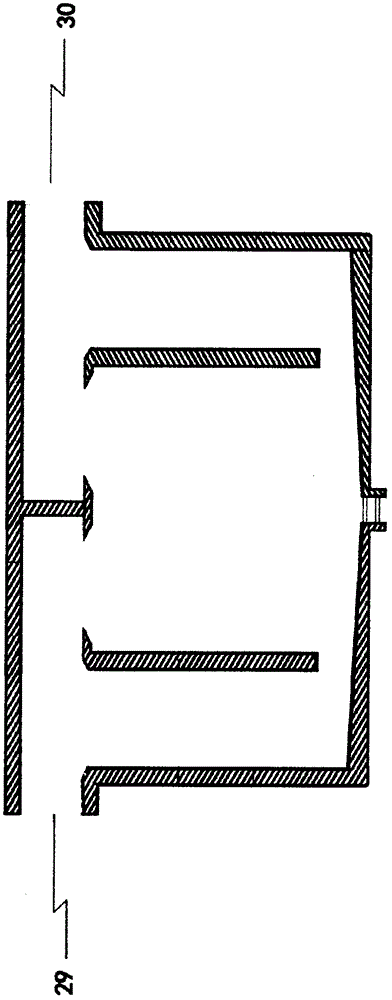

[0081] The following is mainly combined with the accompanying drawings ( Figure 4 ) and attached drawings ( Figure 5 ) The operating principle of the single-stroke pneumatic engine of the present invention is further described. In order to highlight the working principle of the single-stroke pneumatic engine, the description of the structure of the lubrication system will be omitted (for the lubrication scheme, please refer to Figure 8 , Figure 9 , Figure 10 And the description of the aforementioned "structural features of a single-stroke pneumatic engine"). Those skilled in the art should be able to understand that this description omits the lubricating process of the camshaft and other components, including the oil pump and oil pipeline, oil pan, crankcase, engine outer shell and cylinder head, as engine components , although these parts are indispensable in practice, the present invention mainly demonstrates the operating principle of the single-stroke pneumatic en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com