Two-stage fluidized bed-membrane bioreactor and method of treating coking wastewater by using two-stage fluidized bed-membrane bioreactor

A membrane bioreactor, coking wastewater technology, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of ammonia nitrogen and COD emissions that are not up to standard, improve effluent quality and reduce treatment load, the effect of improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

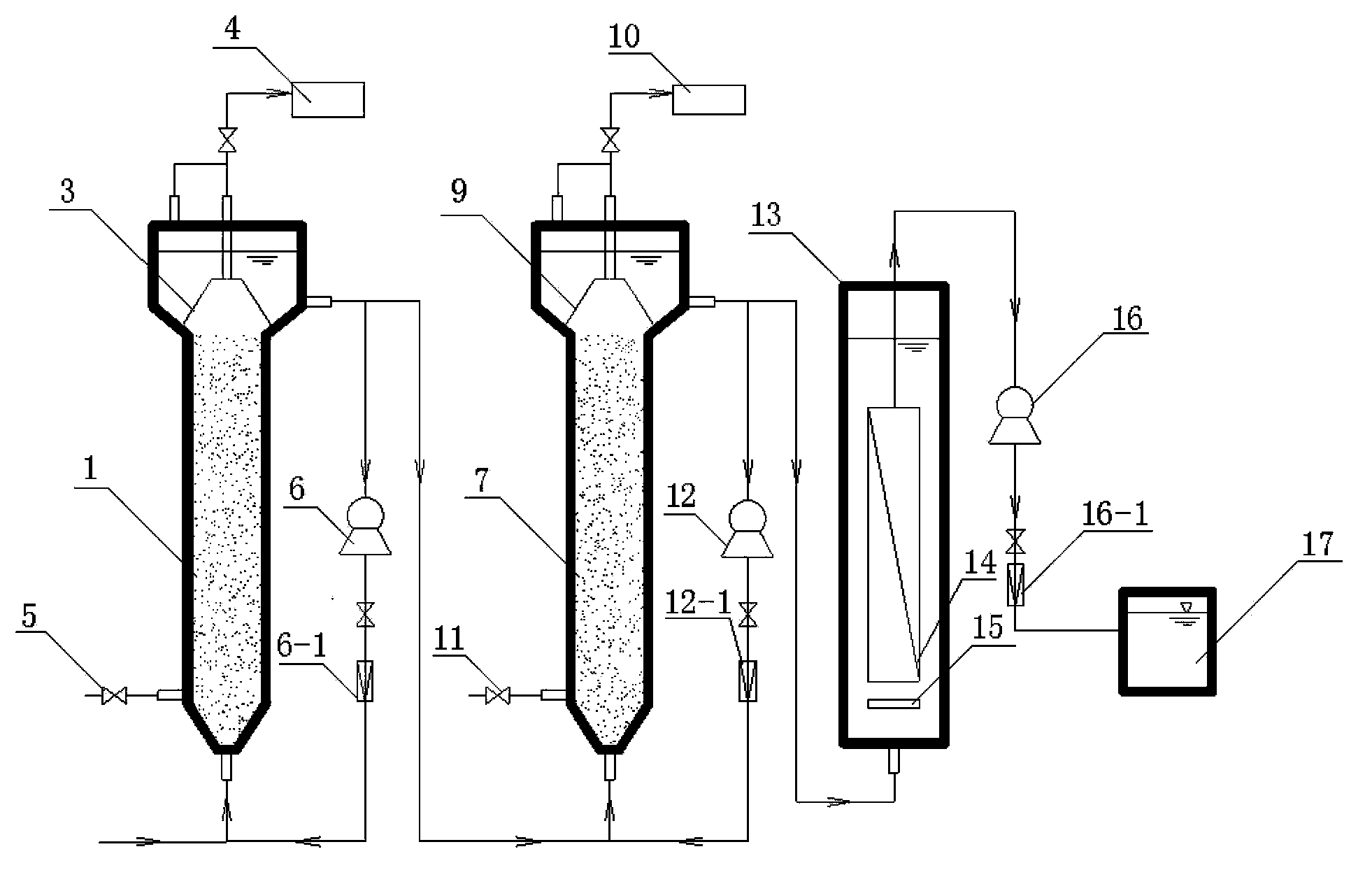

[0019] Specific Embodiment 1: The dual-stage fluidized bed-membrane bioreactor in this embodiment includes a membrane module 14 and an aeration device 15, the shape of the membrane module 14 is hollow fiber type or flat plate type, and the material of the membrane module 14 is Polyvinylidene fluoride, polyvinyl chloride, polyethersulfone, polyacrylonitrile or polypropylene ultrafiltration membrane, the membrane pore diameter of the membrane module 14 is 0.01-0.1 μm, and the suction pressure of the membrane module 14 is 10- 60kPa, the membrane flux is 10~30L / m 2 h.

specific Embodiment approach 2

[0020] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the suction pressure of the membrane module 14 is 10-6020-50kPa, and the membrane flux is 15-2510-30L / m 2 h. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the membrane pore diameter of the membrane module 14 is 0.05 μm. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com