Construction method for curve edge end surface of building water supplying thin-walled stainless steel pipeline

A construction method and technology of stainless steel pipes, applied in water supply main pipelines, water supply pipeline systems, buildings, etc., can solve problems such as waste of raw materials, high manual labor intensity, cumbersome installation process, etc., to reduce consumption, improve labor productivity, and reduce manpower The effect of material resources and time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

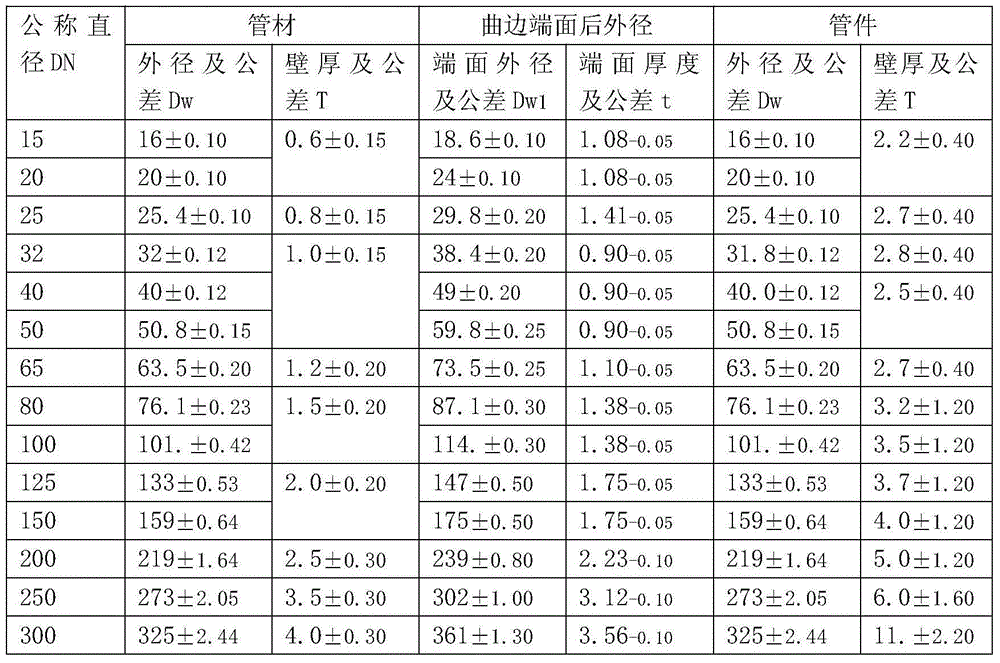

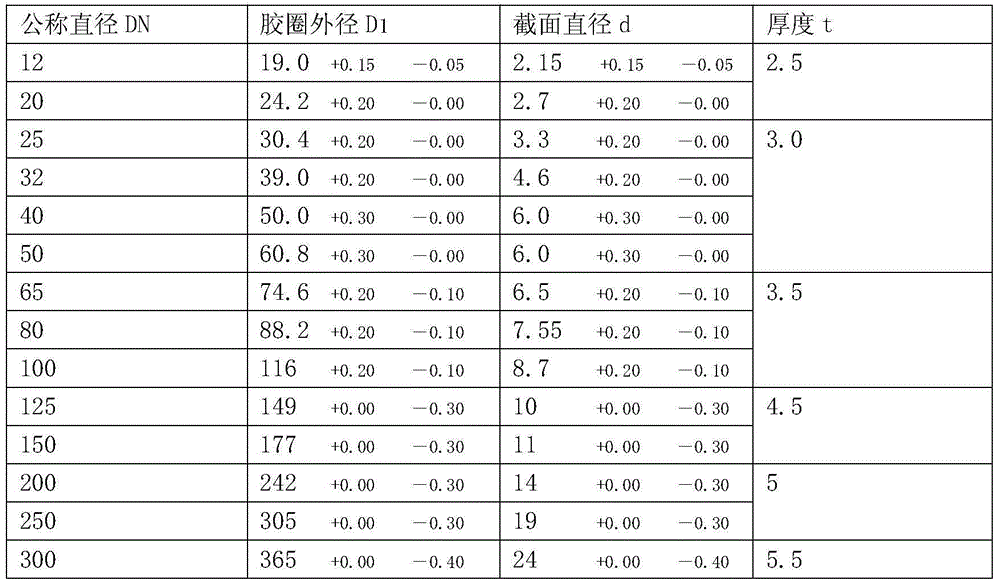

[0039] Chongqing Fuling Central Hospital has a construction area of 34,000 square meters, 15 floors above ground, 3 floors underground, and a total building height of 62.5m. It is a comprehensive building. The original design of the water supply system of the central hospital used thin-walled stainless steel pipe clamping connection technology, and after design modification, the curved-edge end-face connection of thin-walled stainless steel pipes was adopted. Its water supply system is divided into four subsystems: cold water system, hot water system, direct drinking water system, and soft water system. The pipe diameter is DN15-150mm, and the total number of thin-wall stainless steel pipes used is 10982m. The hot water system is insulated.

[0040] The construction process is divided into the following steps: Familiar with the construction drawings and comprehend the design intent → synthesis of each pipeline → joint review of drawings → accurate on-site measurement and deta...

Embodiment 2

[0103] The outpatient and emergency building decoration project of Guizhou Provincial People's Hospital has a construction area of 65,000 square meters, 25 floors in the north, 15 floors in the south, 6 floors in the podium, and a total building height of 99m. It is a large comprehensive building. The water supply system with thin-walled stainless steel pipes with curved edges and end faces is adopted. The water supply system is divided into cold and hot water systems, reclaimed water and reuse systems. The pipe diameters are DN15-DN250. The number of thin-walled stainless steel pipes is not yet total . Among them, the hot water system uses rubber and plastic for insulation, and the reclaimed water and sewage treatment plant are connected to the confluence purification system for reuse. The construction steps of this embodiment 2 are the same as that of embodiment 1. After the completion of the project, most of the pipes of the water supply and reclaimed water system are exp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com