Cellular solid fluctuating micromechanical gyroscope and preparation method thereof

A micro-mechanical gyroscope and honeycomb-shaped technology, which can be used in gyroscope/steering sensing equipment, gyro effect for speed measurement, and microstructure devices without moving elements, etc. It can solve the problems of low sensitivity, poor impact resistance, and high precision. and other problems, to achieve the effect of good structural strength, strong stability and damage resistance, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

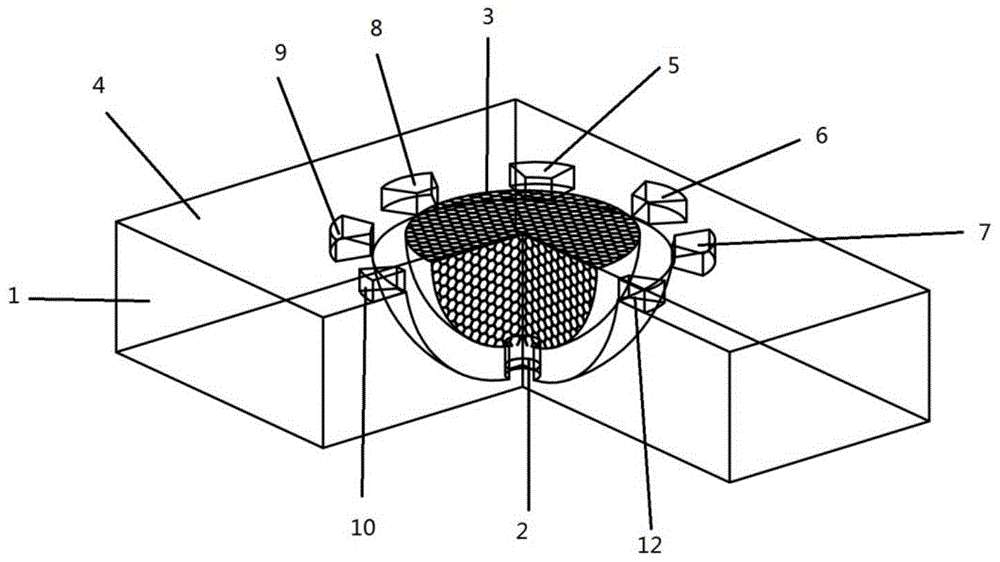

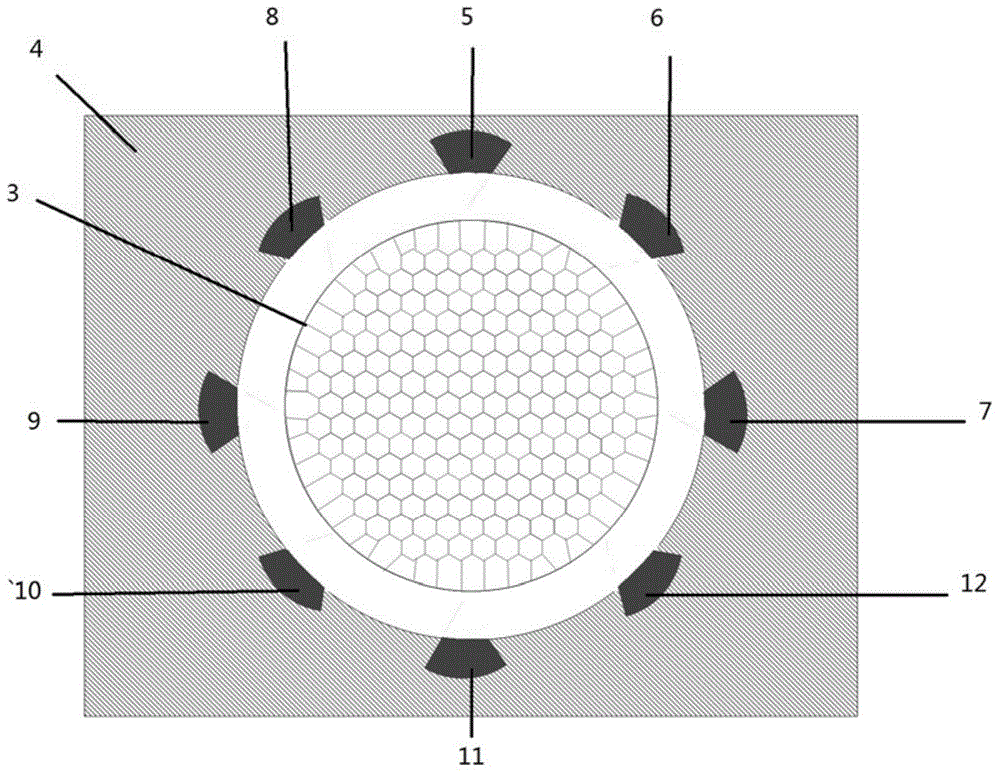

[0030] refer to figure 1 , the present embodiment provides a honeycomb hemispherical solid wave micromachined gyroscope, which includes:

[0031] a substrate 1 with an upper surface 4;

[0032] A honeycomb hemispherical resonator 3 placed on the base;

[0033] The supporting body 2 which is connected to the harmonic oscillator on the base and plays a supporting role;

[0034] And driving electrodes 5, detecting electrodes 6, monitoring electrodes 7, balancing electrodes 12, driving electrodes 11, detecting electrodes 10, monitoring electrodes 9, and balancing electrodes 8 located on the upper surface 4 of the substrate 1 and around the honeycomb resonator;

[0035] Wherein, the drive electrode, the detection electrode, the monitoring electrode, and the balance electrode are a pair, a total of eight, which are evenly distributed on the base around the honeycomb resonator, and the centers of the two electrodes are separated by 45°; the electrodes and the honeycomb There is a ...

Embodiment 2

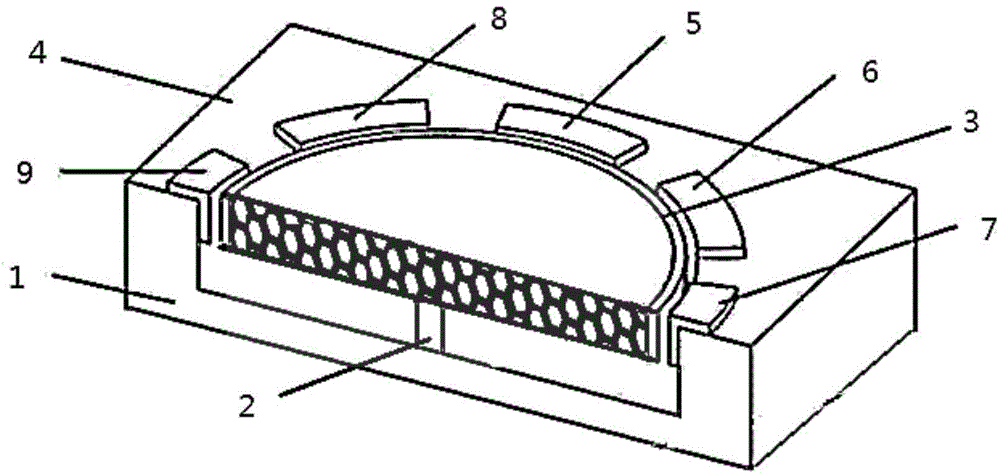

[0047] Embodiment 2 is basically the same as Embodiment 1, except that the structure of the resonator is different. Embodiment 2 uses a honeycomb disk resonator.

[0048] refer to image 3 , the present embodiment provides a honeycomb hemispherical solid wave micromachined gyroscope, which includes:

[0049] A base 1 with an upper surface 4; a honeycomb disc resonator 3 placed on the base; a support body 2 on the base to connect the resonator and play a supporting role; and a honeycomb resonator located on the upper surface 4 Surrounding driving electrodes 5, detecting electrodes 6, monitoring electrodes 7, monitoring electrodes 9, and balancing electrodes 8.

[0050] Wherein, the drive electrode, the detection electrode, the monitoring electrode, and the balance electrode are a pair, a total of eight, which are evenly distributed on the base around the honeycomb resonator, and the centers of the two electrodes are separated by 45°; the electrodes and the honeycomb There is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com