Polarization resistance single line polarization interference and single Woodward prism spectral homodyne laser vibrometer

A laser vibrometer and prism spectroscopic technology, used in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of poor device accuracy, difficult to overcome nonlinear errors, optical path asymmetry, etc., to solve polarization leakage The effect of aliasing with polarization, suppressing polarization leakage and aliasing, and simple optical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described in detail below with reference to the accompanying drawings, and examples will be given.

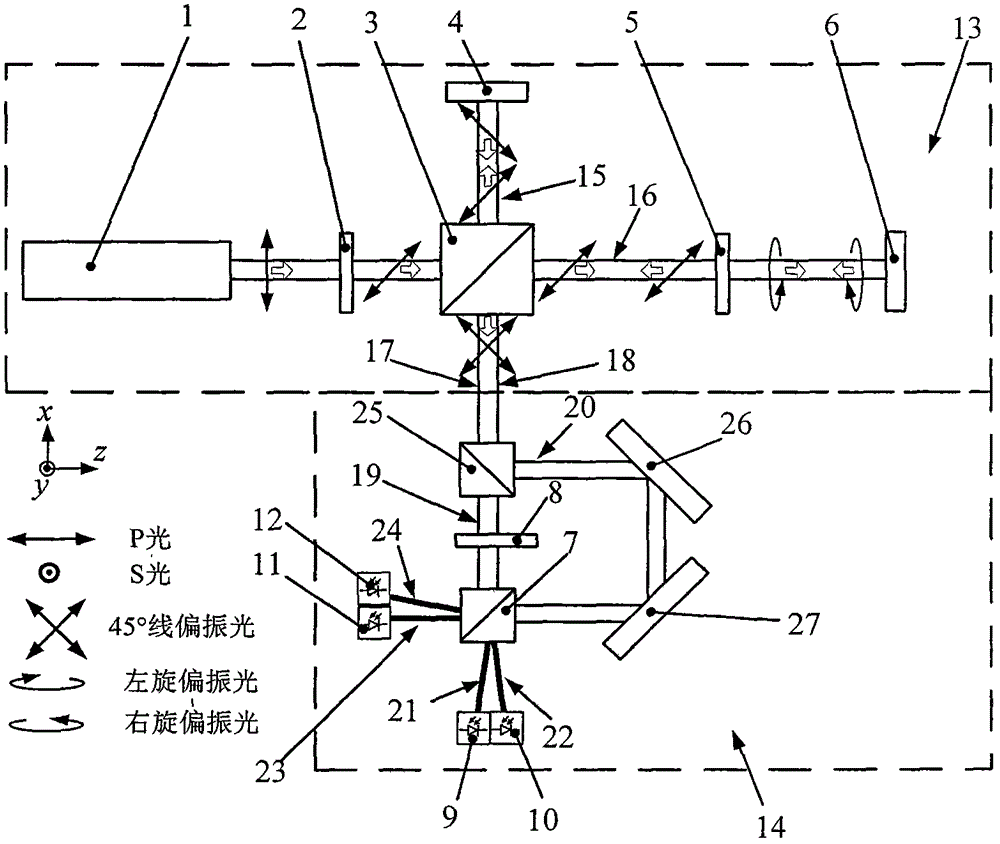

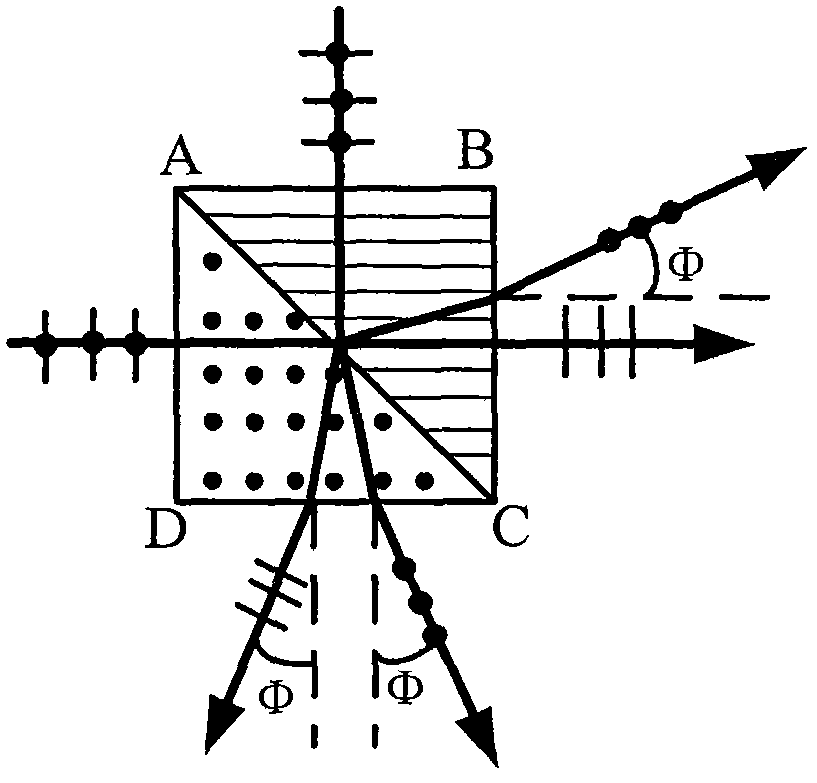

[0030] An anti-polarization aliasing single-line polarization interference and single Wollastedt prism spectroscopic homodyne laser vibrometer is composed of an interference part 13 and a detection part 14, and the interference part 13 is composed of a laser 1, a half The wave plate 2, the first depolarizing beam splitter 3, the measuring mirror 4, the second quarter wave plate 5, and the reference mirror 6 are composed; the laser 1 emits linearly polarized light, which forms a 45° angle after passing through the half wave plate 2 The linearly polarized light is split by the first depolarizing beam splitter 3, the reflected light forms the first beam 15 as the measuring light, and the transmitted light forms the second beam 16 as the reference light; after the first beam 15 is reflected by the measuring m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com