Cloud type dust removal system

A technology of dust removal system and dust removal device, which is applied in the direction of dispersed particle separation, chemical instruments and methods, and the use of liquid separation agents, etc., which can solve the problem of corrosion of fan blades and tail flue, affecting the dilution and diffusion of pollutants, and the large drop in flue gas temperature and other problems, to achieve low cost, good separation effect, and reduce the effect of fluid drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

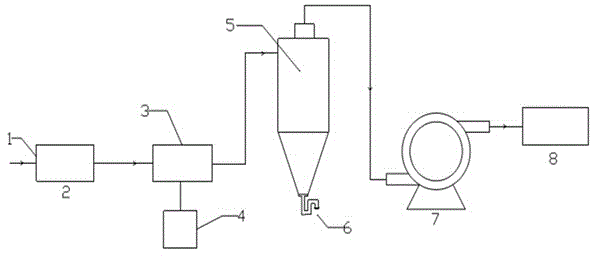

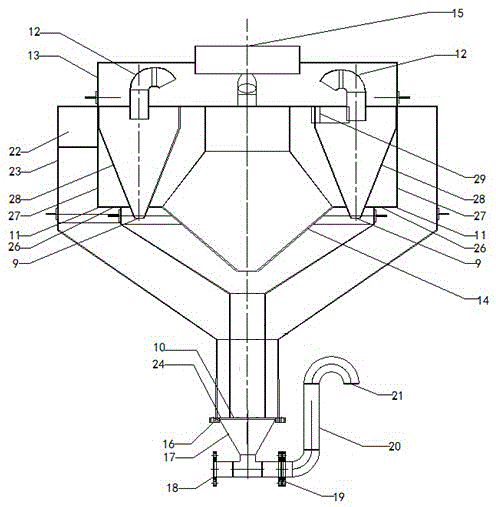

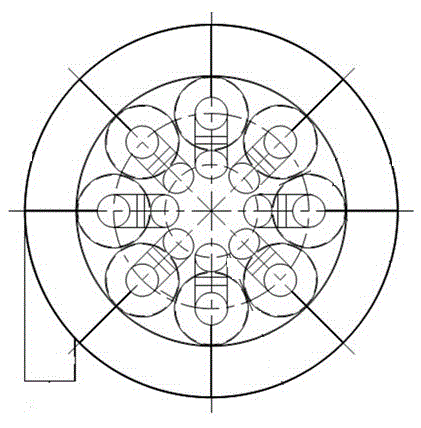

[0038] Embodiment 1, with reference to figure 1 , a cloud-type dust removal system, the front end of the device is a feed inlet 1, and the feed inlet 1 is sequentially connected with a cloud generator or an atomization box 2, a particle growth area or an expansion joint 3, a cloud-type collection area or a cloud-type dust removal The device 5, the induced draft fan 7, and the outlet concentration measurement area 8 are sealed and connected; the bottom of the particle growth area or expansion joint 3 is connected to the sewage tank 4; the bottom of the cloud collection area or cloud dust removal device 5 is connected to the ash discharge device 6 and the particle growth area or expansion joint The outlet of section 3 is tangentially connected to the upper end of the cloud-type collection area or the cloud-type dust collector device. Wherein, the cloud type collection area or cloud type dedusting device 5 (refer to figure 2 , image 3 ) is mainly composed of a central cylind...

Embodiment 2

[0042] Example 2, the cloud generator or atomization box 2 and the particle growth area or expansion joint 3 are not in accordance with each other figure 1 The sequence shown is connected, but the cloud generator or atomization box 2 is installed on the side of the particle growth area or expansion joint 3, the feed port 1 is directly connected to the particle growth area or expansion joint 3, and the cloud generator or atomization box 2 The generated mist is sucked in under negative pressure from the particle growth area or the side of the expansion joint 3, and the dust-laden airflow and the mist are directly in contact with the particle growth area or the expansion joint 3. The rest are the same as embodiment 1.

Embodiment 3

[0043] Embodiment 3, the cloud generator or the atomization box 2 can be installed in the particle growth area or the expansion joint 3 so that the two are integrated. The rest are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com