A liquid level control system and liquid level measurement method based on oblique photography

A technology of liquid level control and oblique photography, which is applied to the configuration of indicating equipment/measuring equipment, manufacturing tools, and level indicators of level members, etc. Liquid level control and other issues, to achieve the effect of low cost, fast measurement speed and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

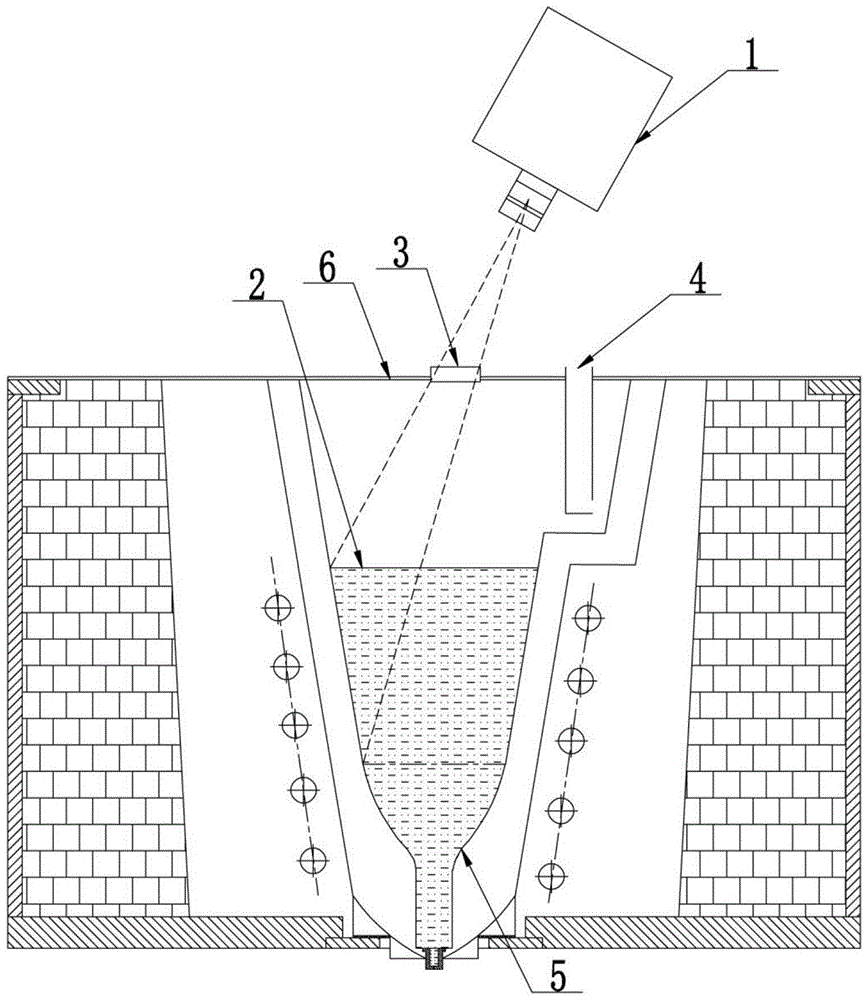

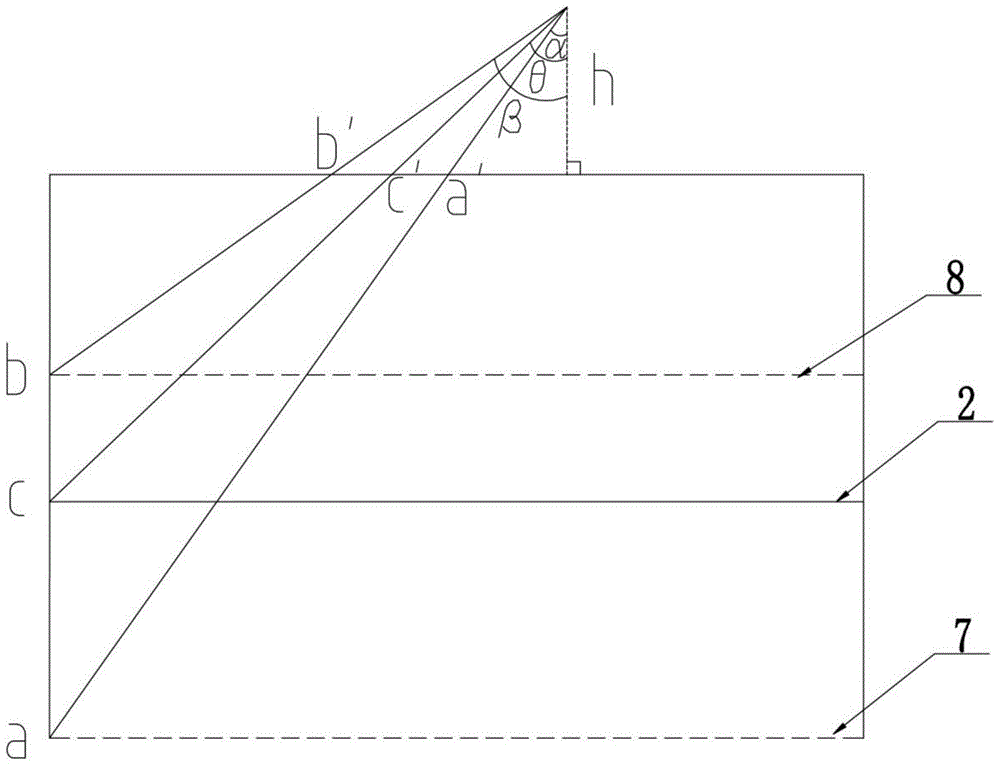

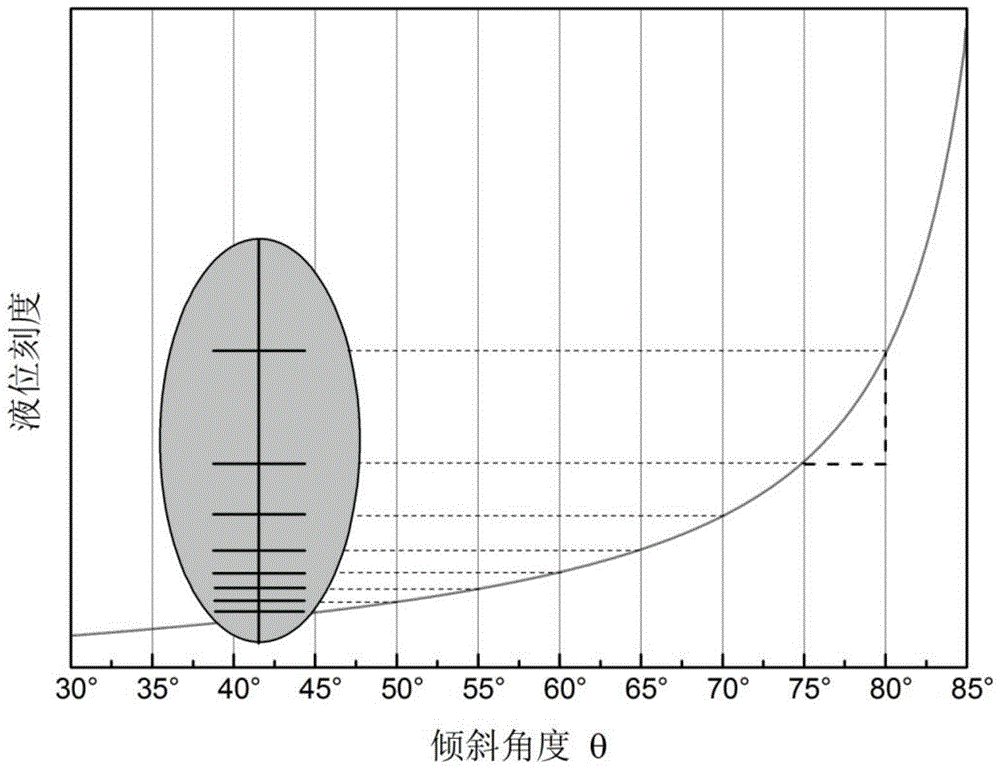

[0020] like figure 1 As shown, a liquid level control system based on oblique photography includes a nozzle package 5, the upper part of the nozzle package is provided with a nozzle cover 6, and the nozzle cover 6 is provided with a quartz glass observation window 3, and the glass observation There is a scale line on the window, the liquid level height 2 in the nozzle package forms a liquid level intersection line with the inner wall of the nozzle package, the scale line is parallel to the liquid level intersection line, and the upper part of the nozzle package is inclined A CCD camera 1 is provided, and the optical axis of the CCD camera can pass through the glass viewing window to photograph the liquid level intersection in the nozzle package, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com