Arc profile cutting discharge processing method based on combined arc breaking and efficient chip removal

A technology of electric discharge machining and arc breaking, which is applied in arc welding equipment, metal processing equipment, welding/cutting media/materials, etc. It can solve problems such as high-efficiency chip removal, affecting the stable and continuous operation of electric discharge machining, and processing short circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

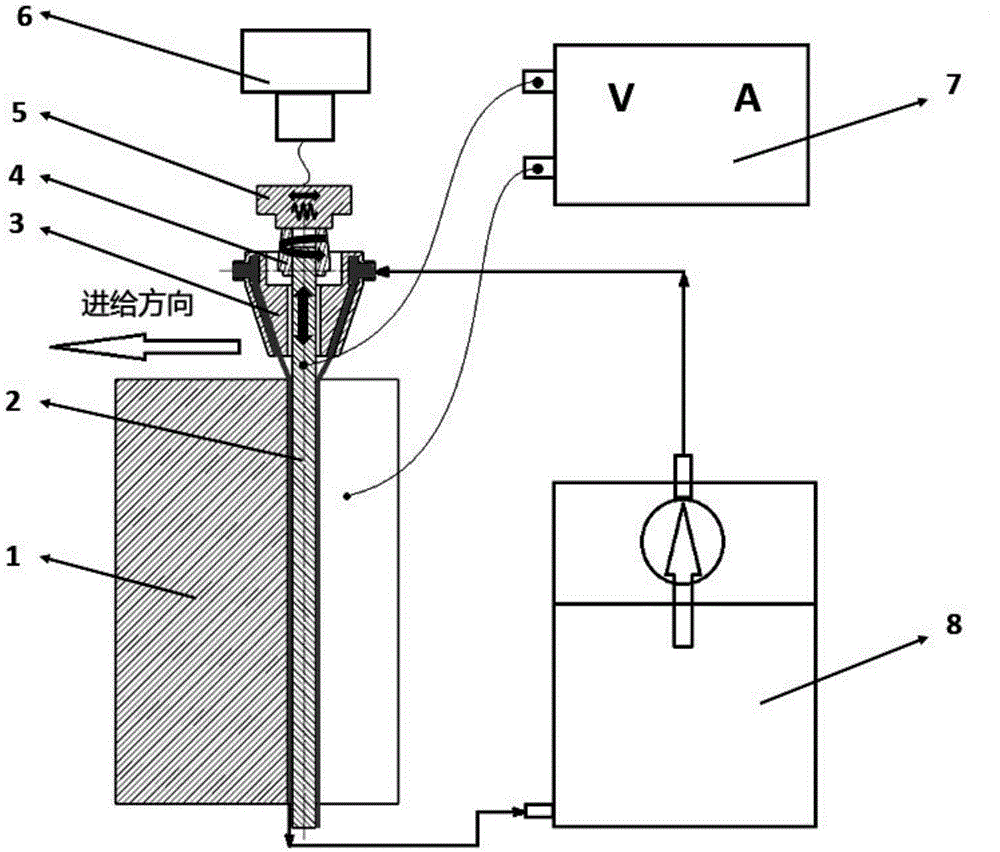

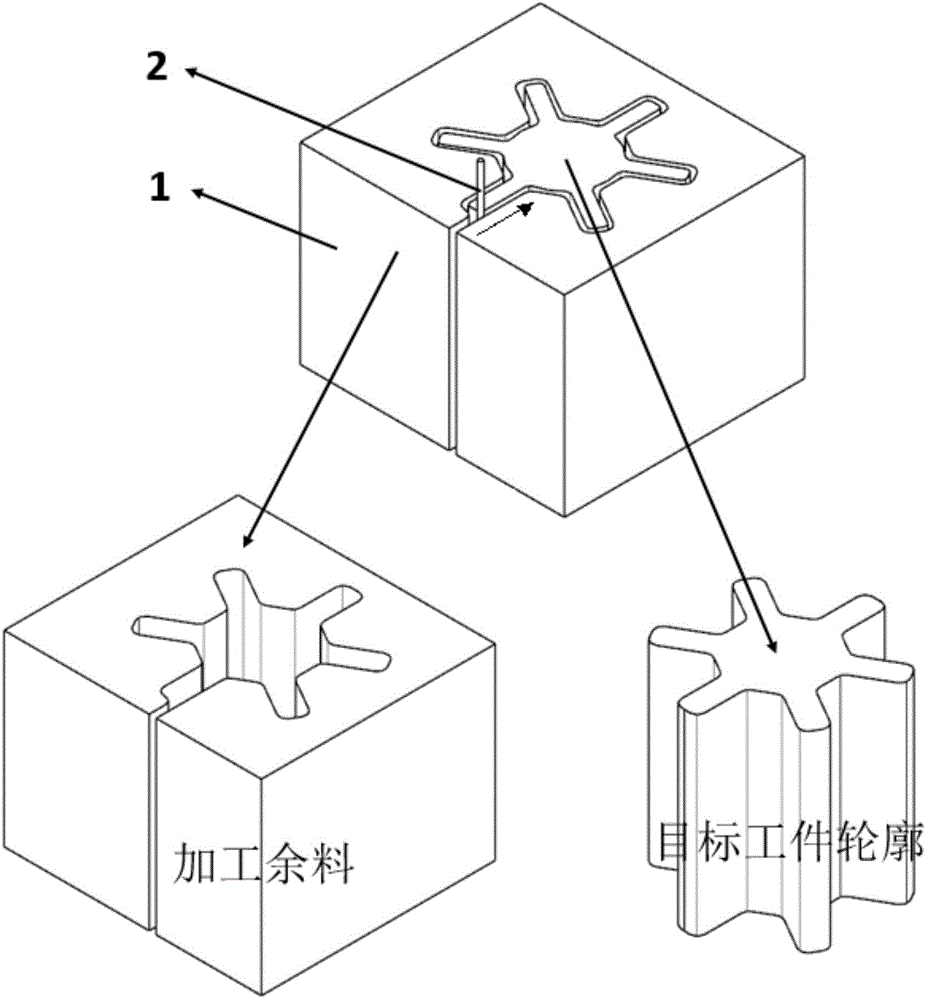

[0034] The contour cutting of arc contour cutting EDM method based on hydrodynamic and mechanical power combined arc breaking and efficient chip removal, such as figure 2 shown. Choose a CNC machine tool with 3-axis linkage, and predetermine the feed path according to the contour characteristics of the target workpiece. The workpiece 1 is a nickel-based superalloy (GH4169), the size is 200*200*150mm (length*width*height), and the electrode 2 is 5mm in diameter. The rod-shaped electrode, the length is 170mm, and the material is graphite. The power parameters are: peak voltage 90V, peak current 600A, pulse width 8000μs and pulse interval 1000μs. The rotation speed of the electrode is 1500r / min, the frequency of the electrode vibration is 200Hz, and the amplitude is 500μm. The working medium is water-based emulsion, and the coaxial flushing outlet pressure is 2.0MPa. Under the above process conditions, the arc contour cutting process is carried out, and finally the workpiece ...

Embodiment 2

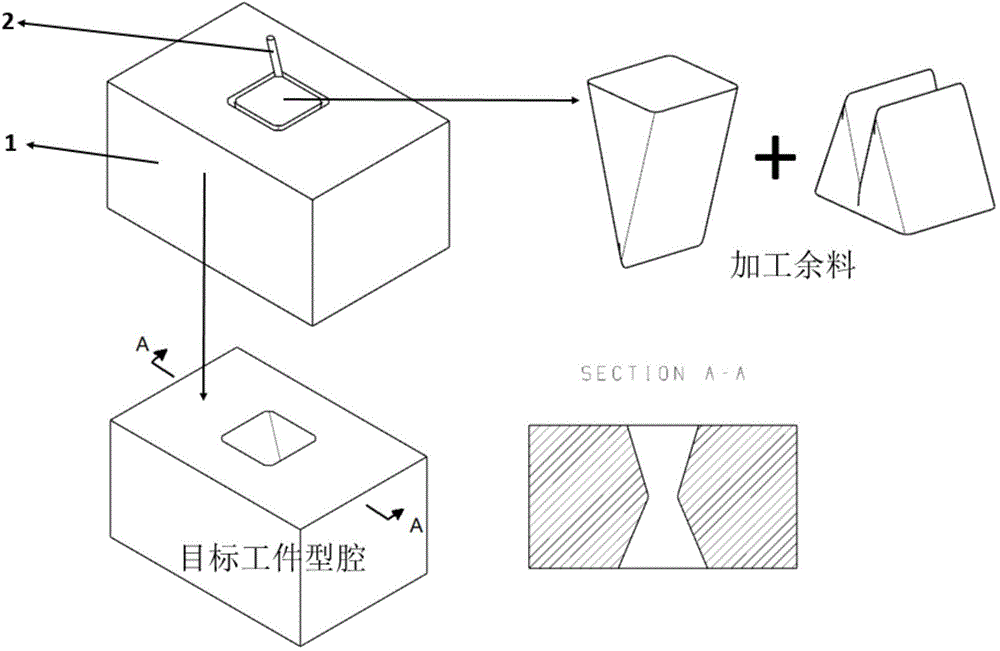

[0036] The cavity machining of the arc contour cutting EDM method based on fluid power and mechanical power composite arc breaking and efficient chip removal, such as image 3 shown. Choose a CNC machine tool with 5-axis linkage, and predetermine the feed path according to the cavity characteristics of the target workpiece. The workpiece 1 is a molybdenum-titanium-zirconium superalloy (TZM), and its size is 300*150*150mm (length*width*height). An internal cavity, electrode 2 is a rod-shaped electrode with a diameter of 5mm, a length of 180mm, and the material is graphite. The power parameters are: peak voltage 90V, peak current 400A, pulse width 6000μs and pulse interval 1000μs. The rotation speed of the electrode is 1500r / min, the frequency of the electrode vibration is 200Hz, and the amplitude is 500μm. The working medium is water-based emulsion, and the coaxial flushing outlet pressure is 2.0MPa. Under the above process conditions, the arc contour cutting process is carr...

Embodiment 3

[0038] The blanking cutting of the electric arc contour cutting EDM method based on fluid power and mechanical power combined arc breaking and efficient chip removal, such as figure 2 shown. Choose a CNC machine tool with 3-axis linkage, and predetermine the feed path according to the characteristics of the target blanking workpiece. The workpiece 1 is a molybdenum-titanium-zirconium superalloy (TZM), the size is a bar with a diameter of 150mm and a length of 800mm, and the electrode 2 is a diameter of 5mm. The rod-shaped electrode is made of graphite. The power parameters are: peak voltage 90V, peak current 600A, pulse width 8000μs and pulse interval 1000μs. The rotation speed of the electrode is 1500r / min, the frequency of the electrode vibration is 200Hz, and the amplitude is 500μm. The working medium is water-based emulsion, and the coaxial flushing outlet pressure is 2.0MPa. Under the above process conditions, the arc contour cutting process is carried out, and finall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com