Plasma arc and MIG arc distance adjustable intelligent composite welding torch

A plasma arc and adjustable technology, which is applied in the field of welding torches where the ion arc and MIG arc are combined, can solve the problems of increasing the life of the plasma electrode, the arc interference does not play a role, and mutual interference, so as to improve the metallurgical performance of the molten pool, promote the Droplet transfer, the effect of improving stirring ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

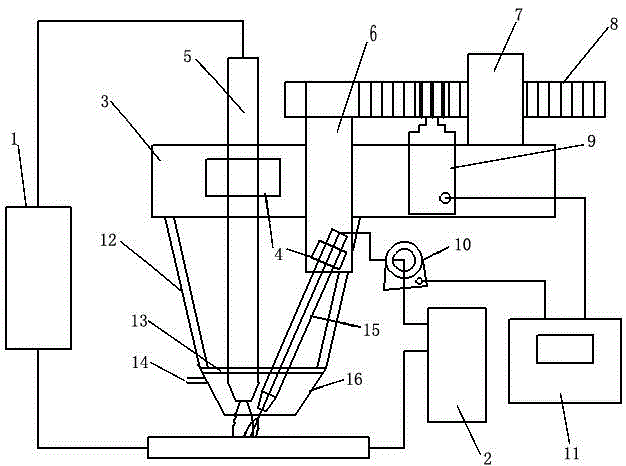

[0017] The intelligent composite welding torch with adjustable distance between plasma arc and MIG arc of the present invention will be described in detail below with reference to the accompanying drawings and specific implementation examples.

[0018] Such as figure 1 As shown, the intelligent composite welding torch with adjustable distance between plasma arc and MIG arc of the present invention includes plasma generator 5, pulse MIG welding torch 15, welding torch bracket 3, bracket rib plate 12, clamp 4, welding torch support 13, shielding gas Cover 16, rack 8, rack support frame 7, connecting plate 6, stepping motor 9, control system 11, current signal collector 10; clamp 4 is installed on the welding torch bracket 3, and the plasma generator passes through the clamp 4 is fixed on the welding torch bracket 3; the rack support frame 7 is fixed on the welding torch bracket 3, the rack 8 passes through the rack support frame 7, and the pulse MIG welding torch 15 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com