Multi-element mineral fertilizer taking copper smelting slag as raw material and preparation method of multi-element mineral fertilizer

A technology of copper smelting slag and multi-element, applied in fertilizer mixture, fertilization device, application, etc., can solve the problem of low utilization rate of copper slag resources, achieve the effect of improving crop quality, improving crop quality, and improving soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

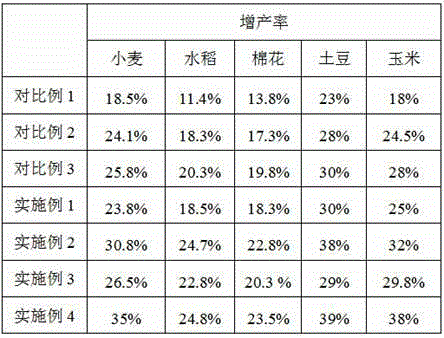

Examples

Embodiment 1

[0018] (1) Pulverize copper smelting slag to 100 mesh;

[0019] (2) Mix the copper smelting slag crushed in step (1) with the calcium-magnesium phosphate fertilizer at a mass ratio of 10:1, so that the effective phosphorus content of the mixture is 2.73%, and an alkaline multi-element mineral fertilizer is obtained.

Embodiment 2

[0021] (1) Pulverize copper smelting slag to 80 mesh;

[0022] (2) Mix the copper smelting slag crushed in step (1) with the calcium-magnesium phosphate fertilizer at a mass ratio of 1:1, so that the effective phosphorus content of the mixture is 15%, and an alkaline multi-element mineral fertilizer is obtained.

Embodiment 3

[0024] (1) Pulverize copper smelting slag to 200 mesh;

[0025] (2) Mix the copper smelting slag crushed in step (1) with superphosphate at a mass ratio of 20:1, so that the available phosphorus content of the mixture is 2.86%, and an acidic multi-element mineral fertilizer is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com