Esterquat-containing modified nano-cellulose as well as preparation method and application thereof

A technology of nano-cellulose and ester-based quaternary ammonium salt, which is applied in the field of organic modification of cellulose, can solve the problems of lack of thermoplasticity, complex technology, application limitations, etc., achieve easy-degradable tensile properties, simple synthesis method, and preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

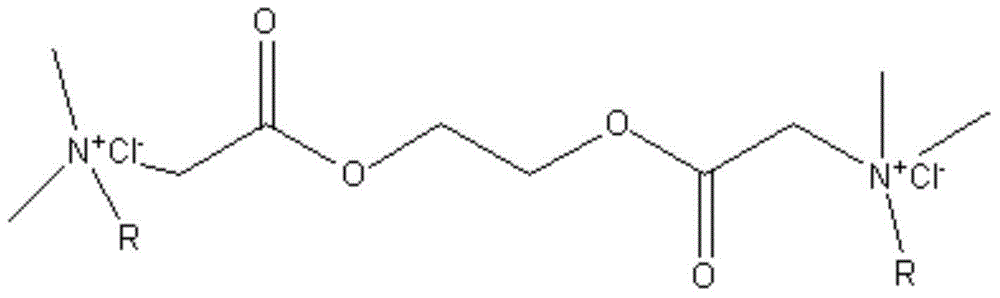

[0025] A kind of ester group-containing quaternary ammonium salt modified nanocellulose is prepared by the following method:

[0026] (1) Dissolve 2g of nanocellulose powder in 100ml of deionized water, ultrasonically treat it for 15 minutes, and obtain a uniformly dispersed nanocellulose aqueous dispersion after fully stirring;

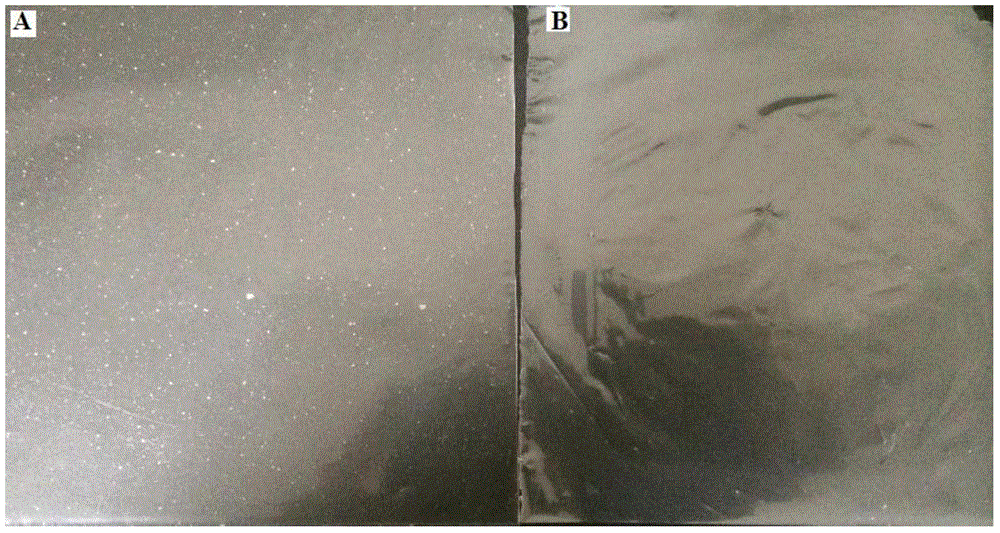

[0027] (2) Add 0.5 g of an ester-containing quaternary ammonium salt surfactant to the nanocellulose aqueous dispersion, heat up to 30° C., fully stir, and react for 2 hours to obtain a white suspension; ultrasonically treat the white suspension for 15 minutes, and then Centrifuge at 10000r / min, remove the supernatant, and obtain a white solid precipitate;

[0028] (3) The white solid precipitate was washed twice with deionized water, vacuum freeze-dried for 24 hours, and the obtained white solid was ground to obtain a powdery solid, that is, a quaternary ammonium salt-modified nanocellulose containing an ester group.

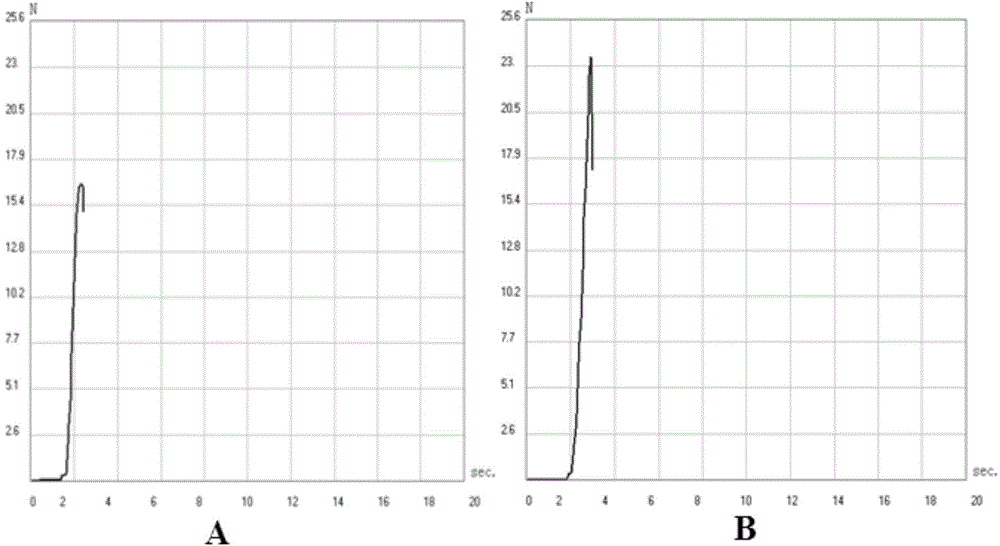

[0029] In the present embodim...

Embodiment 2

[0033] A kind of ester group-containing quaternary ammonium salt modified nanocellulose is prepared by the following method:

[0034] (1) 3 g of nanocellulose powder was dissolved in 100 ml of deionized water, ultrasonically treated for 15 minutes, and fully dispersed to obtain a uniformly dispersed nanocellulose aqueous dispersion;

[0035] (2) Add 0.75g of ester-containing quaternary ammonium salt surfactant to the nanocellulose aqueous dispersion, raise the temperature to 30°C, fully stir, and react for 2h to obtain a white suspension; ultrasonically treat the white suspension for 20min, and then Centrifuge at 10000r / min, remove the supernatant, and obtain a white solid precipitate;

[0036] (3) The white solid precipitate was washed twice with deionized water, vacuum freeze-dried for 24 hours, and the obtained white solid was ground to obtain a powdery solid, that is, a quaternary ammonium salt-modified nanocellulose containing an ester group.

[0037] In the present embo...

Embodiment 3

[0041] A kind of ester group-containing quaternary ammonium salt modified nanocellulose is prepared by the following method:

[0042] (1) Dissolve 4g of nanocellulose powder in 100ml of deionized water, ultrasonically treat it for 15 minutes, and obtain a uniformly dispersed nanocellulose aqueous dispersion after fully stirring;

[0043] (2) Add 1.3g of ester-containing quaternary ammonium salt surfactant to the nanocellulose aqueous dispersion, heat up to 35°C, stir well, and react for 3h to obtain a white suspension; ultrasonically treat the white suspension for 25min, and then Centrifuge at a speed of 11000r / min, remove the supernatant, and obtain a white solid precipitate;

[0044] (3) The white solid precipitate was washed twice with deionized water, vacuum freeze-dried for 24 hours, and the obtained white solid was ground to obtain a powdery solid, that is, a quaternary ammonium salt-modified nanocellulose containing an ester group.

[0045] In the present embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com