Aluminum silicate composition alloy and production method therof

An aluminum-silicon alloy and a production method technology, applied in the field of aluminum alloy, can solve the problems of complex melting and casting process and high cost, and achieve the effects of good strength and toughness, low cost and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

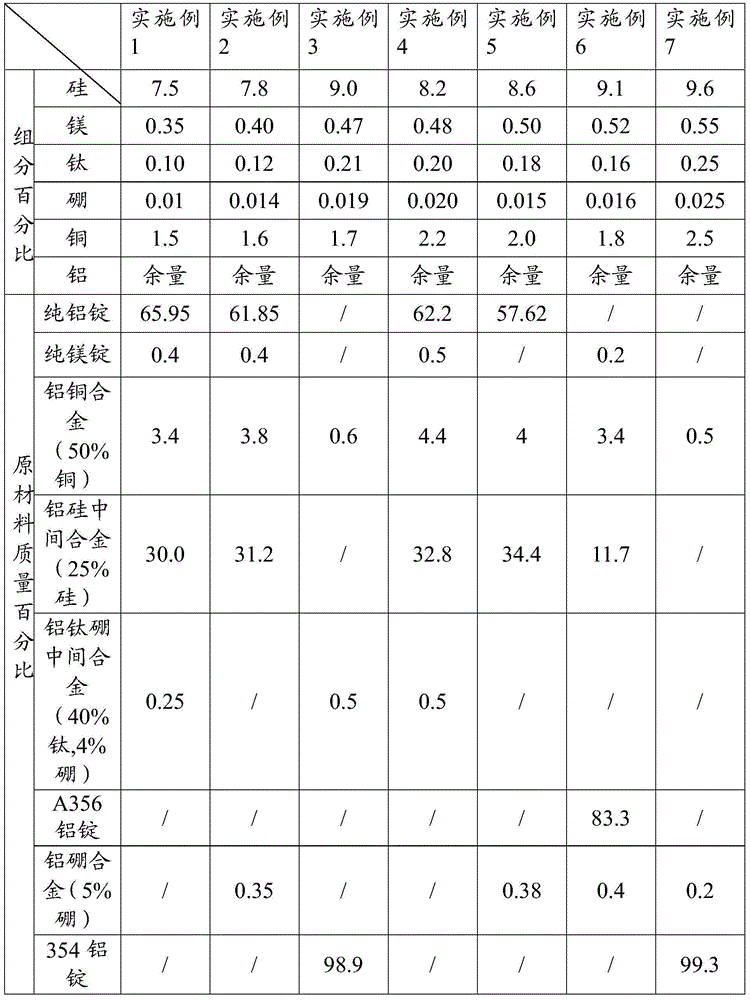

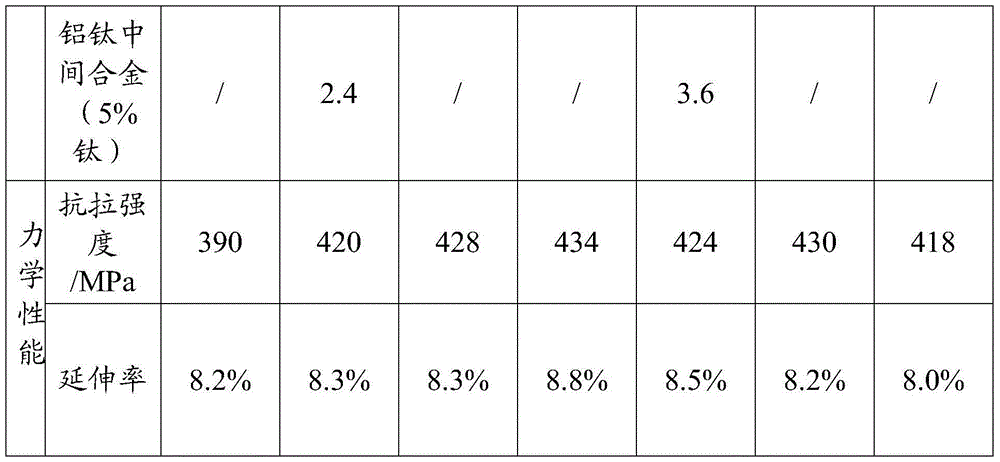

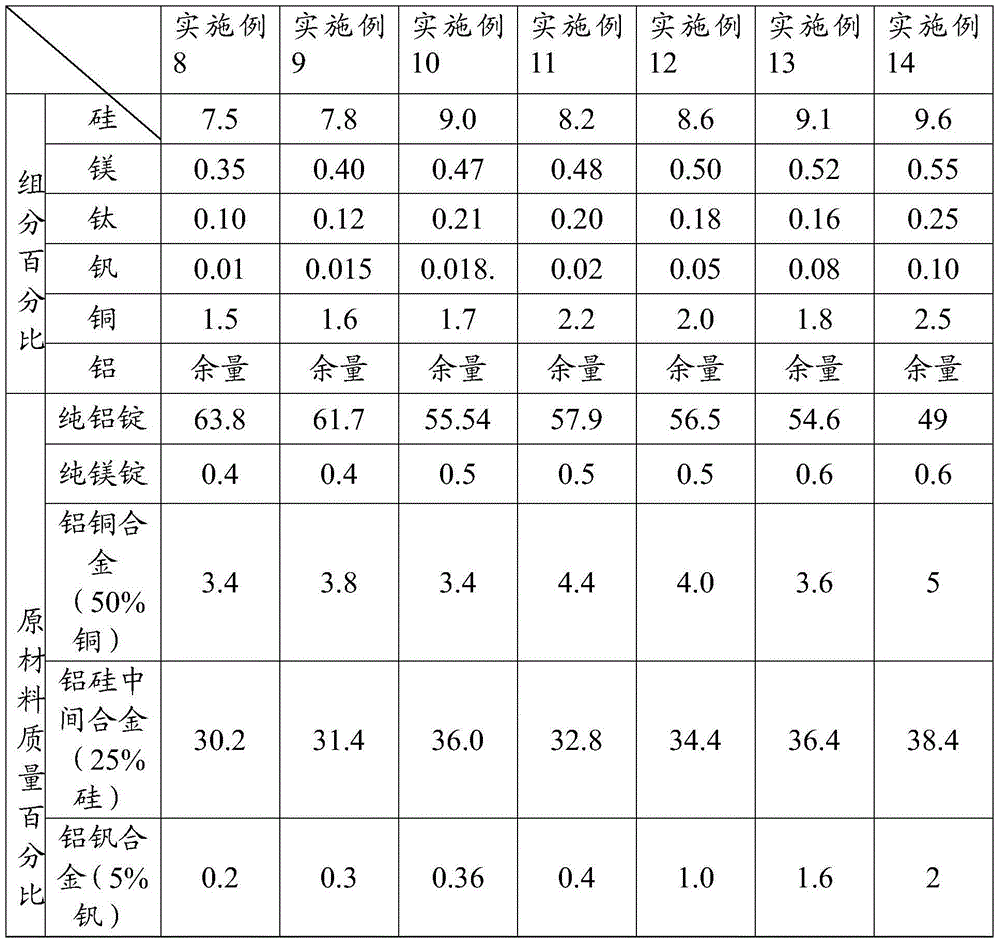

[0038] The content of the components involved in this embodiment is given according to the content specified in Table 1.

[0039] Aluminum silicon alloy is made according to the following steps:

[0040] Step S10, according to the weight percentage of the elements, silicon is 7.5%-10.2%, magnesium is 0.35%-0.60%, titanium is 0.10%-0.25%, vanadium is 0.10%-0.20%, copper is 1.5%-2.5%, and the balance of aluminum is used for raw material preparation. Compare;

[0041] In this embodiment, the raw materials are pure aluminum, pure magnesium, aluminum-copper alloy, aluminum-silicon master alloy, aluminum-titanium master alloy, aluminum-boron master alloy and the like. Titanium-boron alloys or aluminum-titanium-boron intermediate alloys can be used instead of aluminum-titanium intermediate alloys and aluminum-boron intermediate alloys, and other alloys can be added on the basis of aluminum-silicon alloys such as 354 and A356 with fixed components to adjust the composition of the al...

Embodiment 2

[0050] The steps of Example 1 were repeated according to the raw material components in Table 1, and the results of testing the mechanical properties of the aluminum-silicon alloy produced according to the steps described in Example 1 for the raw materials in Example 2 are shown in Table 1.

Embodiment 3

[0052] The steps of Example 1 were repeated according to the raw material components in Table 1, and the results of testing the mechanical properties of the aluminum-silicon alloy produced according to the steps described in Example 1 for the raw materials in Example 3 are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com