Axial cooling radial coil type parallel magnetic circuit electromagnet

A cooled, electromagnet technology applied to electromagnets. It can solve the problems of reducing the safety and reliability of the coil, reducing the dynamic response speed of the electromagnet, weakening the eddy current, etc., to achieve the effects of improving the control accuracy and diesel engine economy, improving the rising speed and decay speed, and good magnetic permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

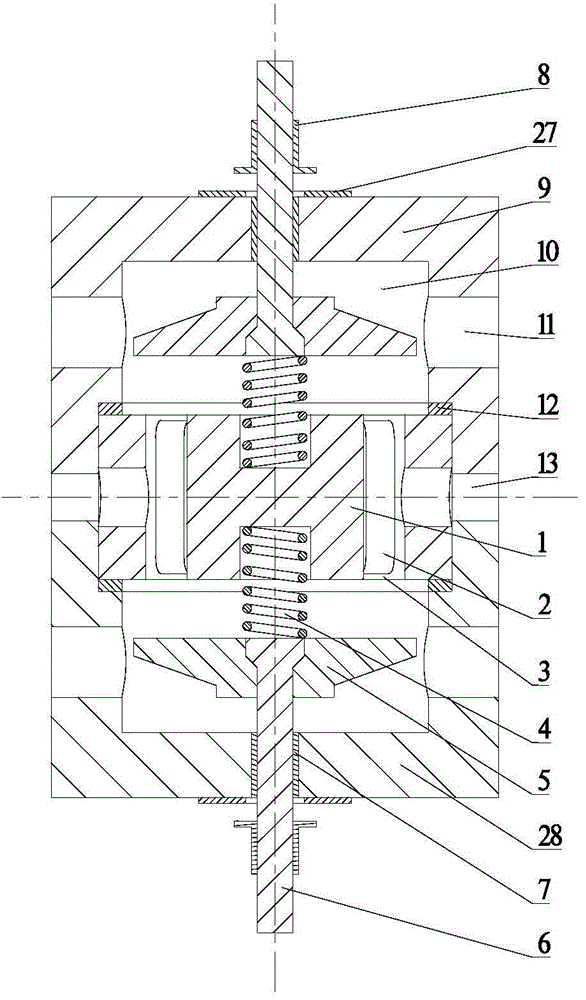

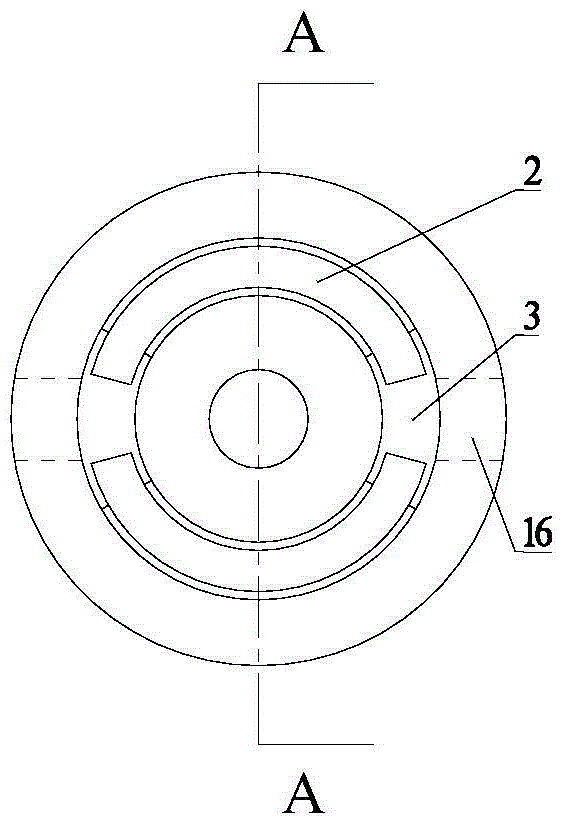

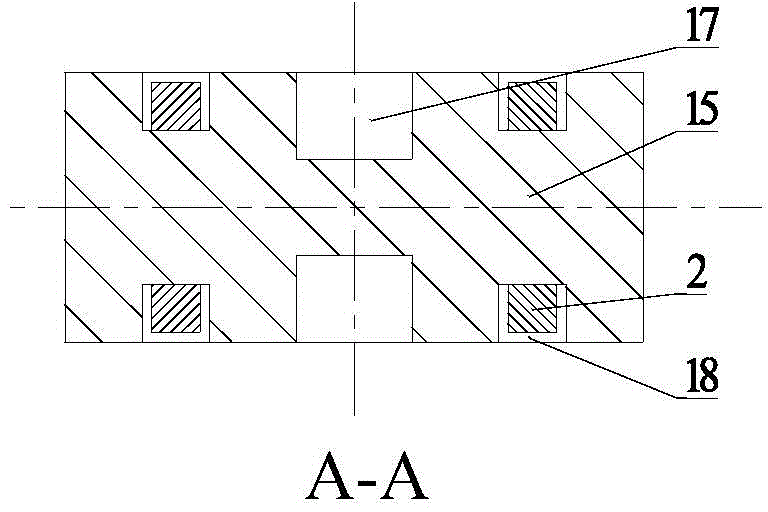

[0033] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0034] combine Figure 1-13 , The composition of the first embodiment of the axially cooled radial coil type parallel magnetic circuit electromagnet of the present invention includes an axially cooled iron core 1, a radial coil 2, an armature return spring 4, an armature 5, and a valve stem 6 , Valve sleeve 7, stop ring 8, rubber buffer gasket 27, upper housing 9, lower housing 28 and residual air gap adjustment ring 12. The upper shell 9 is square, with four bolt through holes 20 on the end face, and the center is provided with an iron core hole 19 and an armature chamber 10 in turn. There is a valve sleeve hole 21, which is embedded with a valve sleeve 7. In addition, the side of the upper housing 9 is provided with an armature chamber coolant inlet 11. The valve stem 6 is fixedly connected with the armature 5, and passes through the valve sleeve 7 of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com