PE electric smelting inner pipe plug

An electrofusion and pipe plug technology, applied in the direction of pipe elements, pipe connection layout, pipe/pipe joints/pipe fittings, etc., can solve the problems of increasing workload, time-consuming operation, reducing the overall strength of cages, etc., to improve construction Efficiency and the effect of ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

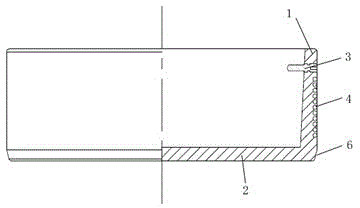

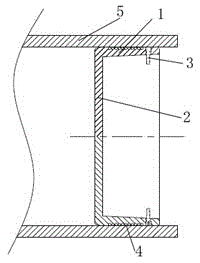

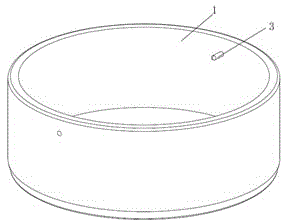

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the PE electrofusion inner pipe plug provided by the present invention includes a pipe plug main body 1 and a partition plate 2 that is closely connected to the pipe plug main body 1 as the bottom surface of the pipe plug main body 1. At the same time, the inner pipe plug also includes a terminal post 3. In this embodiment In the example, the terminal post 3 is a copper terminal post, and the terminal post 3 is vertically installed on the inner wall of the pipe plug main body 1; A heater 4 is arranged inside, and the heater 4 is connected with the terminal post 3 . In this embodiment, the heater 4 is a heating wire, and at the same time, in order to make the electrofusion layer 11 evenly heated, a plurality of heating wires are arranged in the electrofusion layer 11, and the plurality of heating wires are arranged along the axial direction of the pipe plug main body 1 and separated by a certain distance. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com