Novel polymeric aluminum ferric sulphate parparing and curing device

A technology of polymerized aluminum ferric sulfate and solidification device, which is applied in the fields of ferric sulfate, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of inefficient production of solidified polymerized aluminum ferric sulfate preparation device, etc., and achieves simple and easy feeding operation, The effect of convenient transportation and storage, and easy operation of reclaiming materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

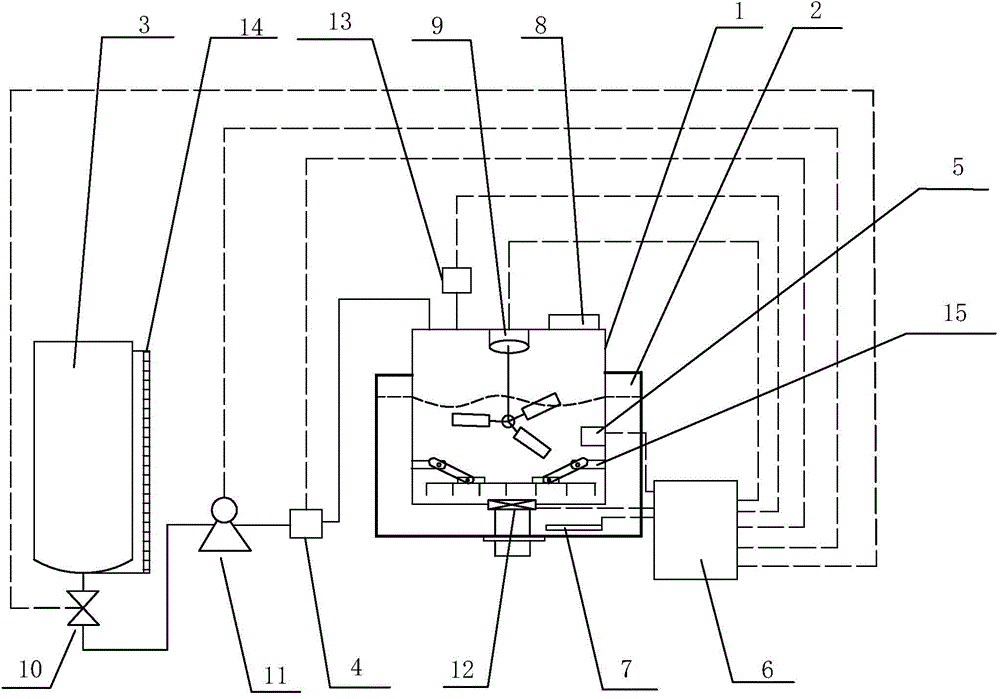

[0011] refer to figure 1 , a novel polymerized aluminum ferric sulfate preparation and curing device of the present invention, comprising a reaction chamber 1, an oil bath 2, a sulfuric acid storage tank 3, a flow detection device 4, a temperature detection device 5, and a control box 6; Injected with phenyl silicone oil and equipped with electric heating tube 7; the reaction chamber 1 is installed in the oil bath 2 through a bracket (not shown in the figure), and the oil bath 2 is supported on the ground by a frame (not shown in the figure) Above; the upper part of the reaction chamber 1 is provided with a material inlet 1 for adding high-iron bauxite, and a material inlet 2 for adding sulfuric acid solution; the bottom of the reaction chamber is provided with a material outlet, and the material outlet is connected to the oil tank through a pipeline. Outside the bath 2; the upper cover of the reaction chamber 1 is connected with a stirring device 9; the temperature detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com