Method for preparing ethylbenzene and styrene through toluene and methanol side chain alkylation

A technology of alkylation and styrene, which is applied in the field of side-chain alkylation of toluene and methanol to produce ethylbenzene and styrene, which can solve the problems of unstable catalyst, low selectivity of ethylbenzene and styrene, and low conversion rate of toluene. To achieve the effect of improving catalytic effect, increasing ion exchange degree and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

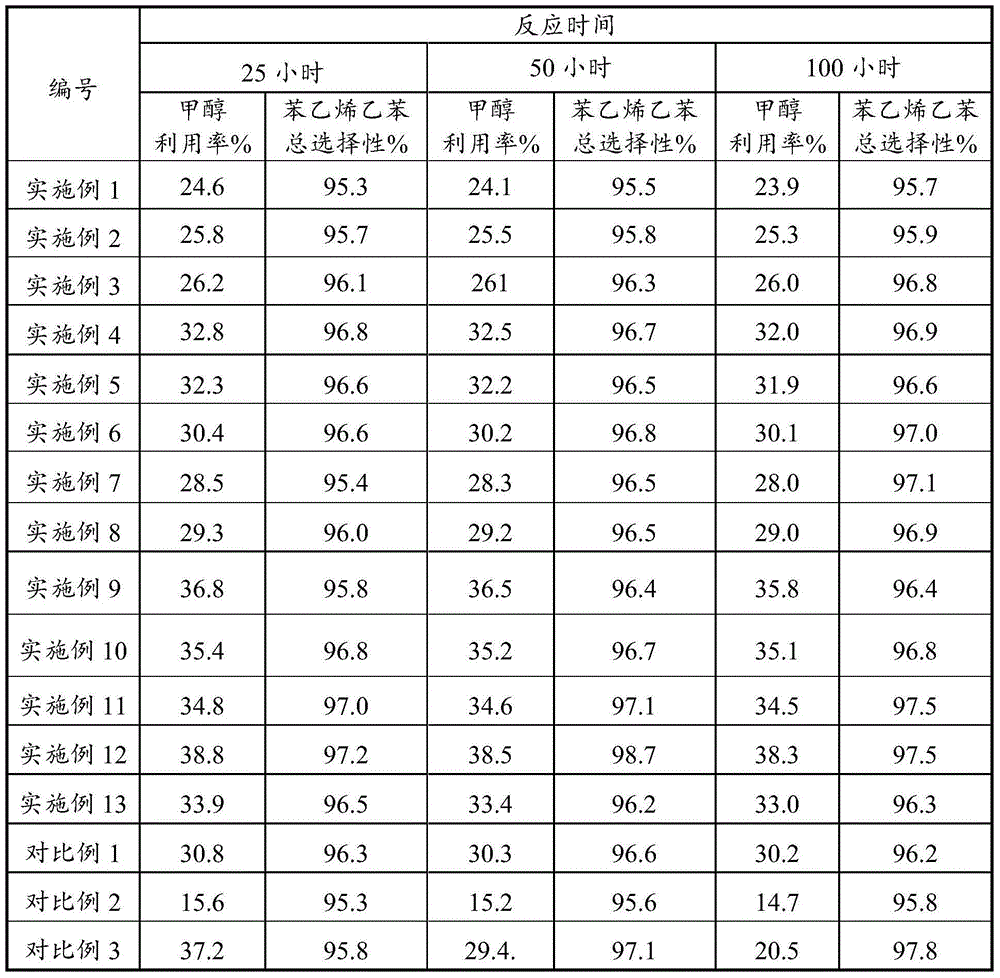

Examples

Embodiment 1

[0032] Take silicon aluminum than SiO 2 / Al 2 o 3 = 2.2 x molecular sieve and SiAl ratio SiO 2 / Al 2 o3 =25 of the ZSM-5 molecular sieve with KNO 3 The solution was ion-exchanged, filtered and dried at 100°C for 10 hours. After the exchange, the ion exchange degree of the sodium ion in the alkali metal ion exchange molecular sieve in the catalyst is more than 85%. After ion exchange, cerium nitrate was used as the rare earth source, and the rare earth cerium was loaded on the two molecular sieves by impregnation method, and the rare earth content was 1%. The dried modified X molecular sieve and modified ZSM-5 molecular sieve were mechanically mixed according to a weight ratio of 1:1, and calcined at 500° C. for 4 hours.

[0033] Press the catalyst obtained above to form a 40-60-mesh granular catalyst, put it into the reactor, and put it under normal pressure with a molar ratio of toluene to methanol of 3:1 for 3.0 hours -1 liquid space velocity, 415°C, N 2 The activity...

Embodiment 2

[0035] Take silicon aluminum than SiO 2 / Al 2 o 3 = 2.2 x molecular sieve and SiAl ratio SiO 2 / Al 2 o 3 =25 ZSM-5 molecular sieves were ion-exchanged with RbCl solution, filtered and dried at 100°C for 10 hours. After the exchange, the ion exchange degree of the sodium ion in the alkali metal ion exchange molecular sieve in the catalyst is more than 85%. After ion exchange, lanthanum nitrate was used as the rare earth source, and the rare earth lanthanum was loaded on the two molecular sieves by impregnation method, and the rare earth content was 1%. The dried modified X molecular sieve and modified ZSM-5 molecular sieve were mechanically mixed according to a weight ratio of 1:1, and calcined at 500° C. for 4 hours.

[0036] Press the catalyst obtained above to form a 40-60-mesh granular catalyst, put it into the reactor, and put it under normal pressure with a molar ratio of toluene to methanol of 3:1 for 3.0 hours -1 liquid space velocity, 415°C, N 2 The activity ev...

Embodiment 3

[0038] Take silicon aluminum than SiO 2 / Al 2 o 3 = 2.2 x molecular sieve and SiAl ratio SiO 2 / Al 2 o 3 =25 of the ZSM-5 molecular sieve with CsNO 3 The solution was ion-exchanged, filtered and dried at 100°C for 10 hours. After the exchange, the ion exchange degree of the sodium ion in the alkali metal ion exchange molecular sieve in the catalyst is more than 85%. After ion exchange, europium nitrate was used as the rare earth source, and the rare earth europium was loaded on the two molecular sieves by impregnation method, and the rare earth content was 1%. The dried modified X molecular sieve and modified ZSM-5 molecular sieve were mechanically mixed according to a weight ratio of 1:1, and calcined at 500° C. for 4 hours.

[0039] Press the catalyst obtained above to form a 40-60-mesh granular catalyst, put it into the reactor, and put it under normal pressure with a molar ratio of toluene to methanol of 3:1 for 3.0 hours -1 liquid space velocity, 415°C, N 2 The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com