Method of using crude extract of olive leaf oleuropein to prepare hydroxytyrosol

A technology of crude oleuropein and hydroxytyrosol, which is applied in the fields of biology and chemistry, can solve the problems of hyperthermia in reaction conditions, expensive enzymes, etc., and achieve the effect of mild method conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

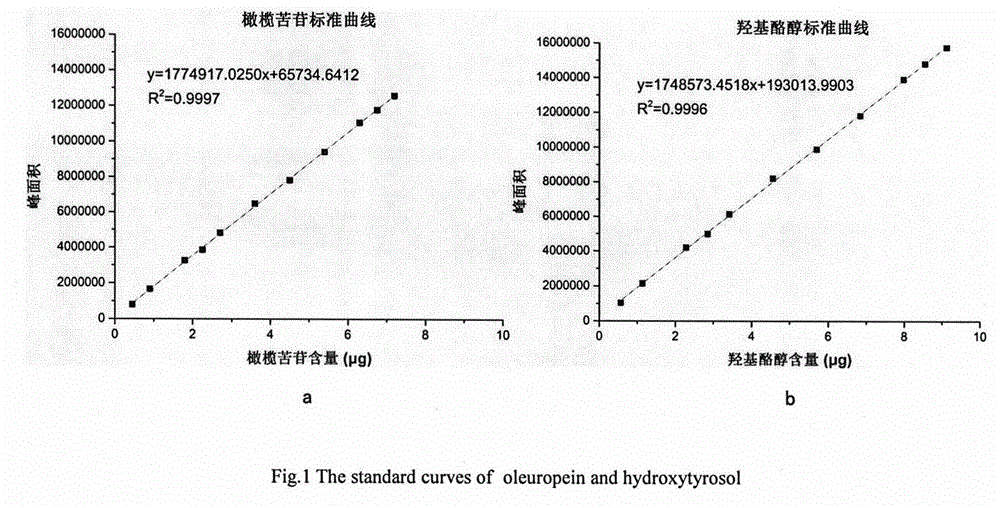

[0037] HPLC Analysis and Calculation Method of Oleuropein and Hydroxytyrosol

[0038] Accurately weigh 4.5mg and 5.7mg of oleuropein and hydroxytyrosol reference substances and place them together in a 10mL volumetric flask, dissolve them with methanol and shake well, dilute to volume and seal tightly to obtain concentrations of 0.45mg / mL and 0.57mg / mL The reference substance is mixed with the standard mother solution. Precisely draw 1, 2, 4, 6, 8, 10, 12, 14, and 16 μL of this standard solution respectively, inject samples, repeat the injection 3 times for each sample, and take the HPLC peak areas of oleuropein and hydroxytyrosol respectively average value. Then, with the HPLC peak area as the ordinate, and the mass (μg) of oleuropein and hydroxytyrosol as the abscissa, respectively, the HPLC standard curve was drawn to obtain the equation.

[0039] The liquid conditions are as follows: the chromatographic column is a C18ODS chromatographic column (250×5mm, 5 μm), the colum...

Embodiment 2

[0042] Acid Hydrolysis of Crude Extract of Olive Leaf Oleuropein

[0043] Weigh 1 g of olive leaf extract into a 250 mL round bottom flask, add 50 mL of 0.2 mol / L HCl bath solution, and place in a constant temperature water bath shaker at 80 °C. After hydrolysis for 6 hours, it was neutralized to neutral, filtered through a 0.45 μm organic membrane, and analyzed by HPLC. Each test was carried out 3 times and the average value was calculated. It is calculated that the HT content can be 7.41% after acid hydrolysis. (OE degradation rate=1-enzymatic hydrolyzate OE mass / extract OE mass (38.6%); HT content=enzymatic hydrolyzate HT mass / extract mass.)

Embodiment 3

[0045] Alkaline Hydrolysis of Crude Extract of Oleuropein from Olive Leaves

[0046] Alkaline hydrolysis conditions: Weigh 1g of olive leaf extract into a 250mL round bottom flask, add 50mL of 0.2mol / L NaOH solution, and place in a constant temperature water bath shaker at 80°C. After hydrolysis for 6 hours, it was neutralized to neutral, filtered through a 0.45 μm organic membrane, and analyzed by HPLC. Each test was carried out 3 times and the average value was calculated. It is calculated that the HT content can be 4.09% after alkali hydrolysis. (OE degradation rate=1-enzymatic hydrolyzate OE mass / extract OE mass (38.6%); HT content=enzymatic hydrolyzate HT mass / extract mass.)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com