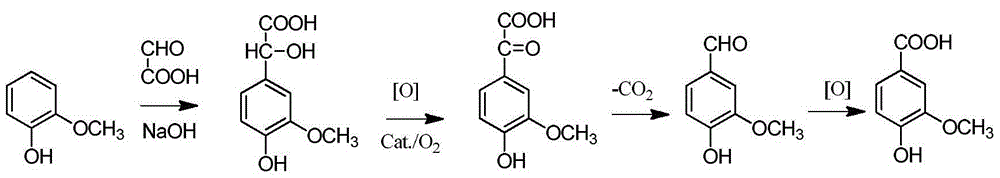

Preparation method for 4-hydroxy-3-methoxy benzoic acid

A technology of methoxybenzoic acid and hydroxyl, applied in the field of preparation of 4-hydroxy-3-methoxybenzoic acid, can solve the problems of harsh reaction conditions, high production cost, low safety, etc. The effect of low production cost and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

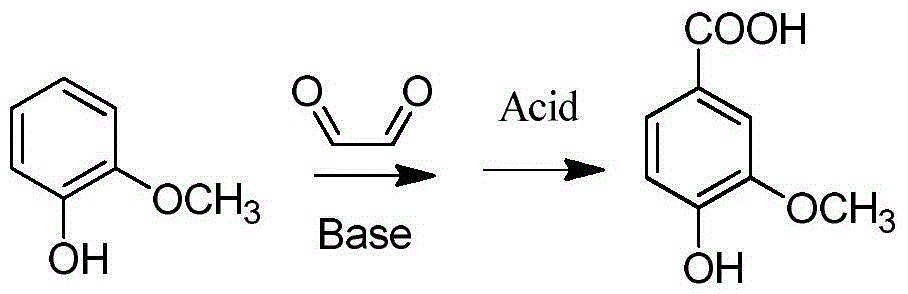

Method used

Image

Examples

Embodiment l

[0024] The 500ml three-necked flask is equipped with a magnetic stirrer, a thermometer, and a detachable reflux condensing device. Add 24.8g (0.2mol) guaiacol, then add 23.2g 50% glyoxal (0.2mol) (that is, the molar ratio of guaiacol to glyoxal is 1:1), add 10% hydroxide Sodium adjusts the pH value to 12.0-12.5, stirs, and reacts at 35-40° C. for 6.0 hours. After the reaction is completed, dilute hydrochloric acid is used to adjust the pH value of the reaction solution to 2-3. After the product is extracted 3 times with ethyl acetate, it is concentrated under reduced pressure to obtain the crude product. The HPLC analysis content of the product vanillic acid is 25%, and the crude product is recovered under reduced pressure. Guaiacol, the raw material for the reaction, and the residue were recrystallized with water to obtain 6.3 g of a white solid, with a reaction selectivity of 83% and a yield of 75%.

[0025] m.p.206~207℃(lit.m.p.208~210℃); 1H NMR (500MHz, DMSO-d6)d 12.73(br...

Embodiment 2

[0027] The 500ml three-necked flask is equipped with a magnetic stirrer, a thermometer, and a detachable reflux condensing device. Add 12.4g (0.1mol) guaiacol, then add 23.2g 50% glyoxal (that is, the molar ratio of guaiacol to glyoxal is 1:2), add 10% potassium hydroxide solid to adjust the pH value 11.5-12.0, stirred, 30 ~ 35 ℃ heat preservation reaction for 6.0 hours. After the reaction is completed, dilute sulfuric acid is adjusted to adjust the pH of the reaction solution to 2-3. After the product is extracted 3 times with ethyl acetate, it is concentrated under reduced pressure to obtain the crude product. The product vanillic acid HPLC content is 18%, and the crude product is recovered under reduced pressure. The raw material was guaiacol, and the residue was crystallized with water to obtain 2.3 g of white powdery crystals, with a reaction selectivity of 81% and a yield of 70%.

Embodiment 3

[0029] The 500ml three-necked flask is equipped with a magnetic stirrer, a thermometer, and a detachable reflux condensing device. Add 12.4g (0.1mol) guaiacol, then add 46.4g 50% glyoxal (that is, the molar ratio of guaiacol to glyoxal is 1:4), add 30% sodium hydroxide to adjust the pH value 13.0-13.5, stirred, and kept at 45-50°C for 2-2.5 hours. After the reaction is completed, adjust with dilute hydrochloric acid to adjust the pH value of the reaction solution to 2-3. After the product is extracted 3 times with ethyl acetate, it is concentrated under reduced pressure to obtain the crude product. The HPLC content of the product vanillic acid is 16%. The raw material guaiacol, the residue was recrystallized with water to obtain 1.69g of white solid, the reaction selectivity was 73%, and the yield was 58%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com