Method for preparing styrene-acrylate copolymer

A technology of acrylate and styrene, which is applied in the field of polymer copolymer preparation, can solve the problems of expensive dispersants and complex production processes, and achieve the effects of reducing production costs, simple implementation steps, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) In a reactor equipped with a reflux condensing device, add 0.5 g of carboxymethyl cellulose and 50 g of deionized water, heat it in a water bath to 80° C., and stir to dissolve it;

[0026] (2) Take by weighing 0.3g initiator dibenzoyl peroxide, place in the container that cleans and dry, add monomer 2g styrene and 8g methyl methacrylate, join the reaction of step (1) after dissolving device;

[0027] (3) Control the stirring speed at 350 rpm, and react at a constant temperature for 4 hours to form copolymer beads;

[0028] (4) After stopping the reaction, the copolymer beads were washed with water, filtered, and dried to obtain transparent bead-like styrene-acrylate copolymers. Optical microscope photographs of styrene-acrylate copolymers are shown in figure 1 .

Embodiment 2

[0030] (1) In a reactor equipped with a reflux condensing device, add 0.5 g of hydroxypropyl methylcellulose and 50 g of deionized water, heat it in a water bath to 80° C., and stir to dissolve it;

[0031] (2) Take by weighing 0.3g initiator dibenzoyl peroxide, place in the container that cleans and dry, add monomer 2g styrene and 8g methyl methacrylate, join the reaction of step (1) after dissolving device;

[0032] (3) Control the stirring speed at 350 rpm, and react at a constant temperature for 4 hours to form copolymer beads;

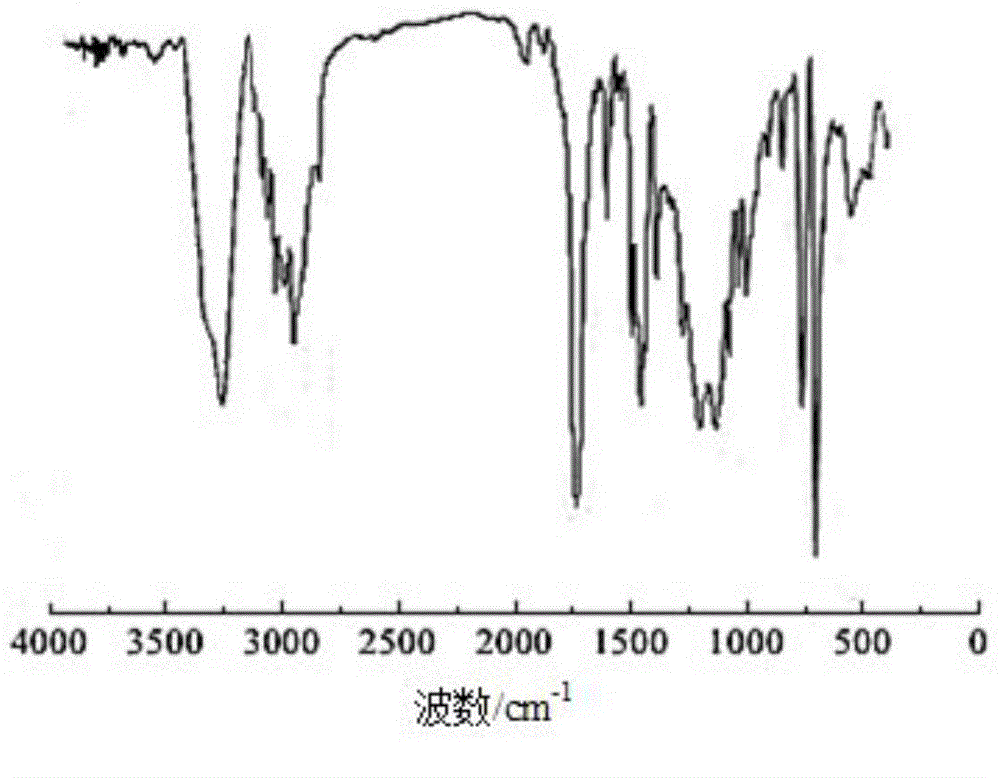

[0033] (4) After stopping the reaction, the copolymer beads were washed with water, filtered, and dried to obtain transparent bead-like styrene-acrylate copolymers. Optical microscope photographs of styrene-acrylate copolymers are shown in figure 2 , see the infrared spectrum image 3 .

Embodiment 3

[0035] (1) In a reactor equipped with a reflux condensing device, add 0.5 g of hydroxypropyl methylcellulose and 50 g of deionized water, heat it in a water bath to 80° C., and stir to dissolve it;

[0036] (2) Take by weighing 0.3g initiator dibenzoyl peroxide, place in the container that cleans and dry, add monomer 10g styrene and 0.1g methyl methacrylate, join the step (1) after dissolving in the reactor;

[0037] (3) Control the stirring speed at 350 rpm, and react at a constant temperature for 4 hours to form copolymer beads;

[0038] (4) After stopping the reaction, the copolymer beads were washed with water, filtered, and dried to obtain transparent bead-like styrene-acrylate copolymers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com