Plugging agent special for building roof crack

A leak-stopping agent and construction technology, applied in the field of leak-stopping agents, can solve problems such as leakage and inability to form grouting channels, and achieve the effects of cost reduction, good adaptability, and low possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

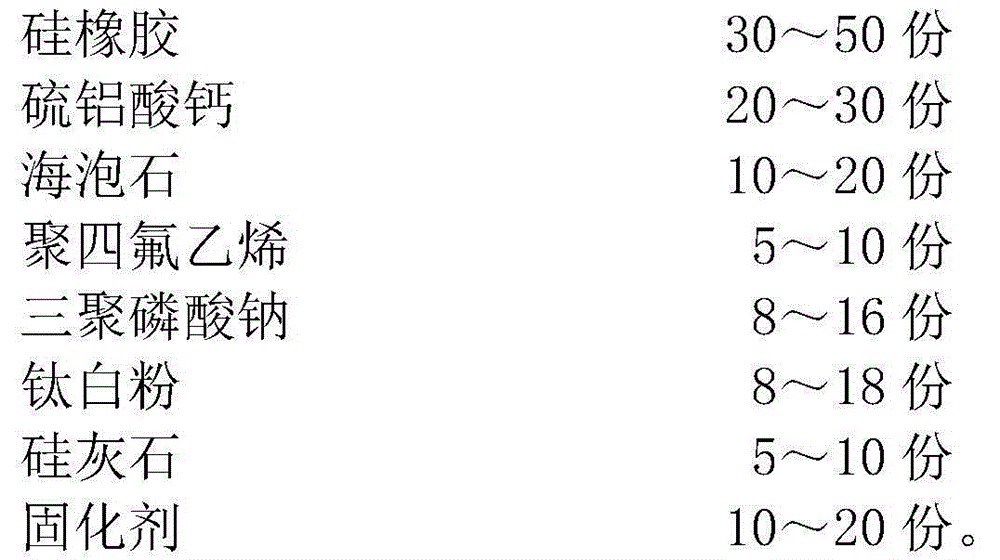

[0023] 1) Take the raw material by the following parts by weight:

[0024]

[0025] 2) All the raw materials are added into the mixing equipment and stirred evenly to obtain the product.

[0026] The curing agent is a mixture of 20 parts of lithium chloride, 5 parts of talcum powder and 5 parts of bentonite; the particle size of polytetrafluoroethylene is 0.02 mm; the particle size of the talc powder is 0.012 mm.

Embodiment 2

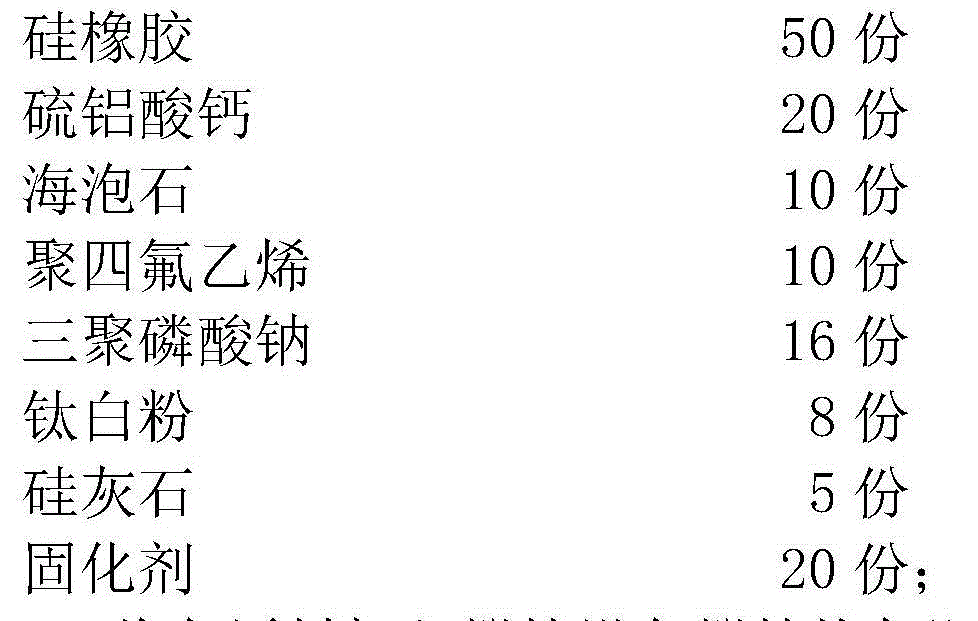

[0028] 1) Take the raw material by the following parts by weight:

[0029]

[0030] 2) All the raw materials are added into the mixing equipment and stirred evenly to obtain the product.

[0031] The curing agent is a mixture of 18 parts of lithium chloride, 6 parts of talcum powder and 7 parts of bentonite; the particle size of polytetrafluoroethylene is 0.03 mm; the particle size of the talc powder is 0.031 mm.

Embodiment 3

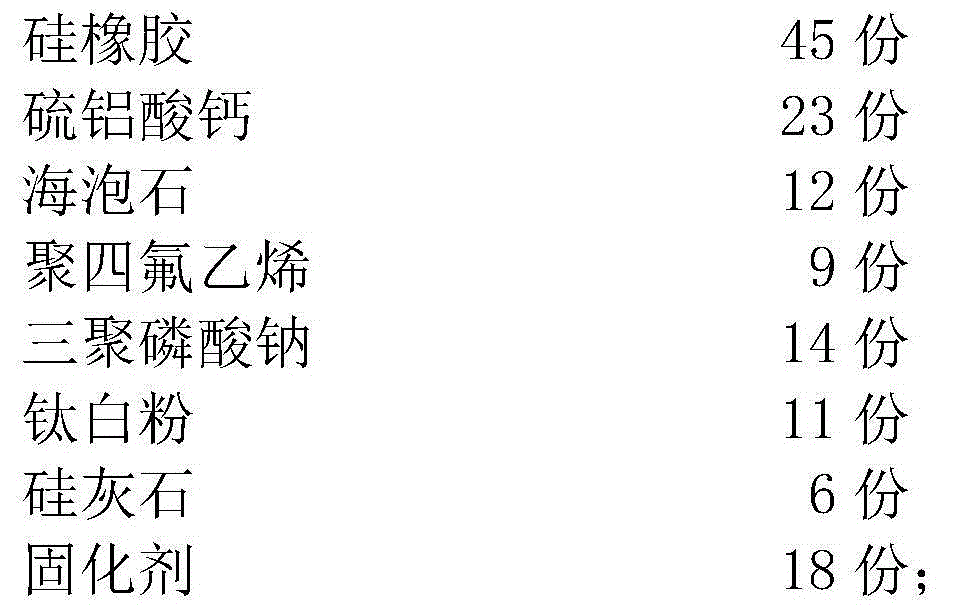

[0033] 1) Take the raw material by the following parts by weight:

[0034]

[0035]

[0036] 2) All the raw materials are added into the mixing equipment and stirred evenly to obtain the product.

[0037] The curing agent is a mixture of 15 parts of lithium chloride, 7 parts of talcum powder and 8 parts of bentonite; the particle size of polytetrafluoroethylene is 0.05 mm; the particle size of the talc powder is 0.047 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com