A method for prolonging the time of snow-melting effect of environmental protection snow-melting agent

A technology of action time and snow-melting agent, which is applied in the field of traffic environment safety, can solve the problems of short snow-melt time, high corrosion of metal and concrete, etc., and achieve the effects of prolonging action time, good light transmission, and slowing down metal corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

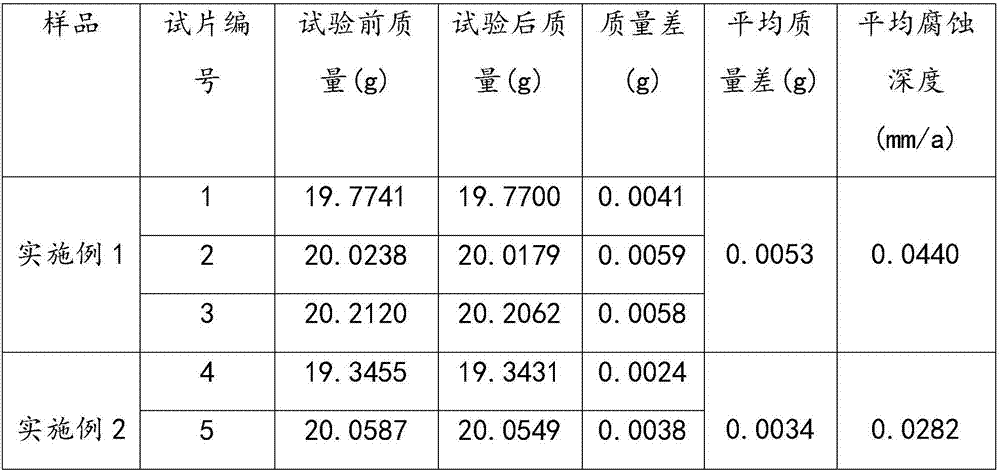

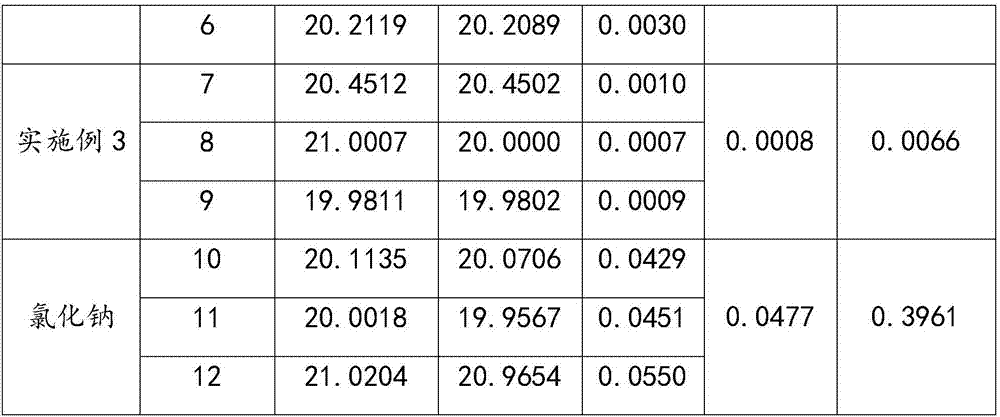

Embodiment 1

[0027] (1), 70 parts of sodium chloride and 20 parts of calcium chloride are stirred and mixed to obtain a chloride salt mixture; 35 parts of sodium silicate, 30 parts of sodium dihydrogen phosphate, 10 parts of sodium tartrate and 25 parts of thiourea are mixed to obtain Corrosion inhibitor; 60 parts of urea and 40 parts of sodium bicarbonate are mixed according to the proportion to obtain a pH regulator;

[0028] (2), 90 parts of chlorine salt mixtures, 5 parts of corrosion inhibitors and 5 parts of pH regulators prepared in step (1) were stirred and mixed to obtain the crude product of deicing agent;

[0029] (3) Stir, pulverize and granulate the homogeneously mixed snow-melting agent rough product, and pass through a standard sieve with an aperture of 6 mm to obtain granular environmental-friendly snow-melting agent;

[0030] (4) Place the solid PDMS in the lower layer of the closed heating furnace, and place the granular environmentally friendly snow-melting agent prepare...

Embodiment 2

[0033] (1), 70 parts of sodium chloride and 20 parts of calcium chloride are stirred and mixed to obtain a chloride salt mixture; 35 parts of sodium silicate, 30 parts of sodium dihydrogen phosphate, 10 parts of sodium tartrate and 25 parts of thiourea are mixed to obtain Corrosion inhibitor; 60 parts of urea and 40 parts of sodium bicarbonate are mixed according to the proportion to obtain a pH regulator;

[0034] (2), 90 parts of chlorine salt mixtures, 5 parts of corrosion inhibitors and 5 parts of pH regulators prepared in step (1) were stirred and mixed to obtain the crude product of deicing agent;

[0035] (3) Stir, pulverize and granulate the homogeneously mixed snow-melting agent rough product, and pass through a standard sieve with an aperture of 6 mm to obtain granular environmental-friendly snow-melting agent;

[0036] (4) Place the solid PDMS in the lower layer of the closed heating furnace, and place the granular environmentally friendly snow-melting agent prepare...

Embodiment 3

[0039] (1), 70 parts of sodium chloride and 20 parts of calcium chloride are stirred and mixed to obtain a chloride salt mixture; 35 parts of sodium silicate, 30 parts of sodium dihydrogen phosphate, 10 parts of sodium tartrate and 25 parts of thiourea are mixed to obtain Corrosion inhibitor; 60 parts of urea and 40 parts of sodium bicarbonate are mixed according to the proportion to obtain a pH regulator;

[0040] (2), 90 parts of chlorine salt mixtures, 5 parts of corrosion inhibitors and 5 parts of pH regulators prepared in step (1) were stirred and mixed to obtain the crude product of deicing agent;

[0041] (3) Stir, pulverize and granulate the homogeneously mixed snow-melting agent rough product, and pass through a standard sieve with an aperture of 6 mm to obtain granular environmental-friendly snow-melting agent;

[0042] (4) Place the solid PDMS in the lower layer of the closed heating furnace, and place the granular environmentally friendly snow-melting agent prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com