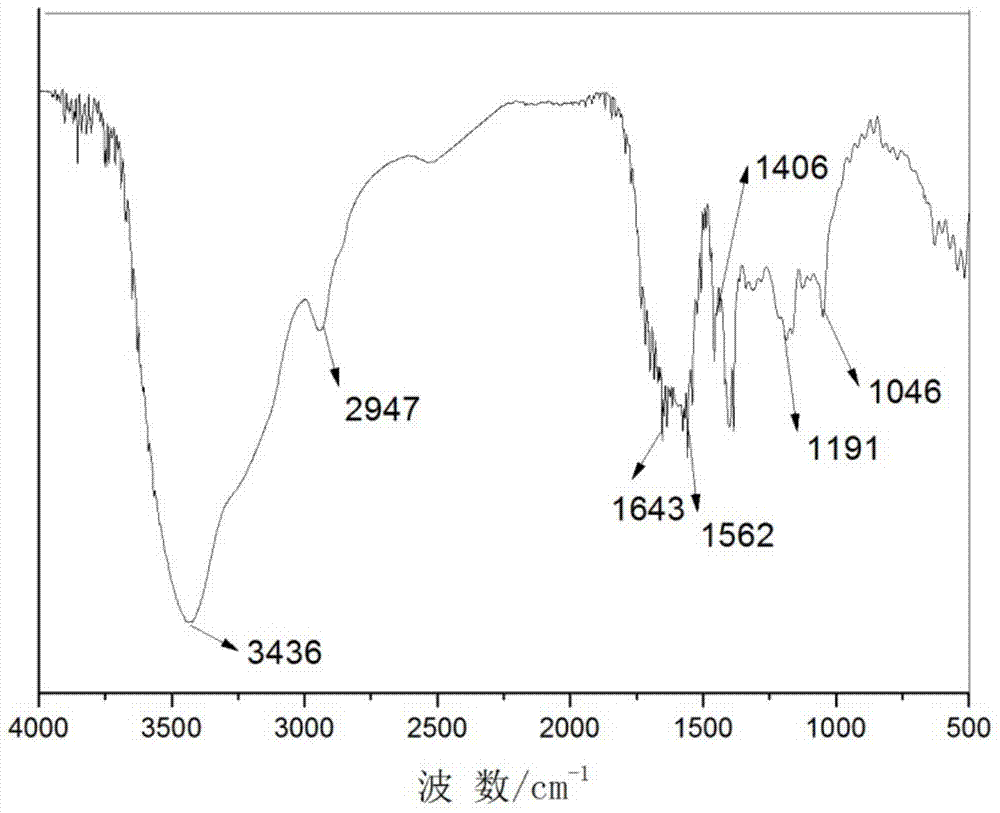

Temperature-resistant and salt-resistant polymer fluid loss reducer and preparation method thereof

A filtrate reducer, temperature-resistant and salt-resistant technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of low applicable temperature, high applicable cost, high production cost, etc., and achieve good salt and temperature resistance Performance, mild and controllable conditions, simple and feasible method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

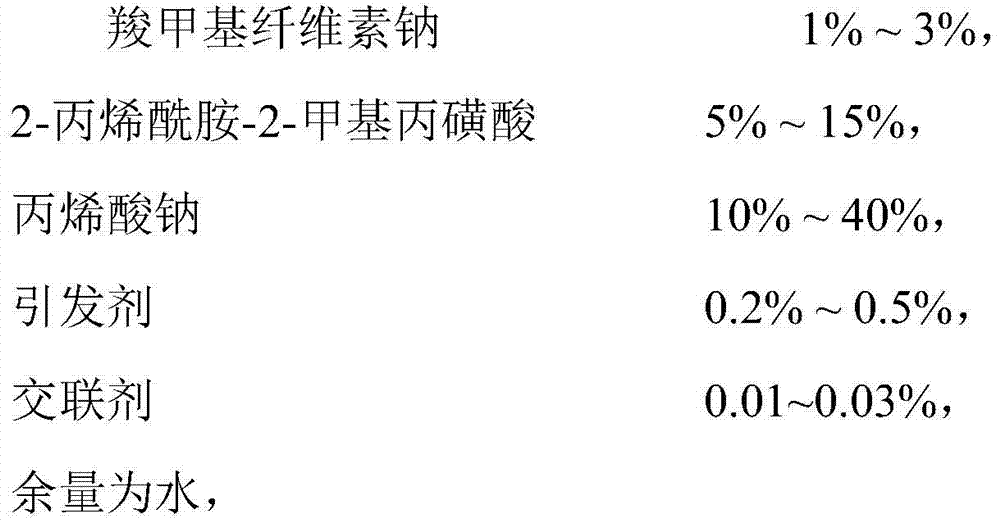

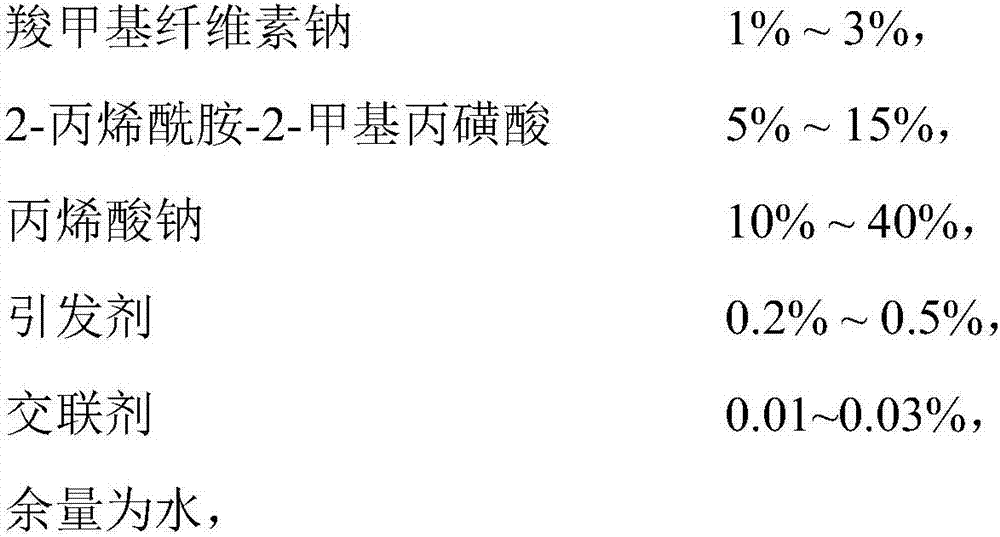

Method used

Image

Examples

Embodiment 1

[0022] Add 2g of sodium carboxymethylcellulose to the reactor, then add 20mL of water to the reactor, stir and heat to 40℃ for gelatinization for 20min, add 5g 2-acrylamide-2-methylpropanesulfonic acid, 20g Stir the sodium acrylate aqueous solution evenly, add 0.2g potassium persulfate initiator and 0.010g N,N-methylenebisacrylamide crosslinker in sequence, react at 50℃ for 4 hours, and wash twice with ethanol and distilled water. , Drying, crushing and granulating to obtain a white powdery product.

Embodiment 2

[0024] Add 2g of sodium carboxymethylcellulose to the reactor, then add 20mL of water to the reactor, stir and heat to 50℃ for gelatinization for 30min, add 5g of 2-acrylamido-2-methylpropanesulfonic acid, Stir 25g of sodium acrylate aqueous solution uniformly, add 0.3g of sodium persulfate initiator and 0.010g of N,N-methylenebisacrylamide crosslinking agent in sequence, react at a constant temperature of 60°C for 3 hours, and wash twice with ethanol and distilled water respectively. Dry, crush and granulate to obtain a white powder product.

Embodiment 3

[0026] Add 3g of sodium carboxymethylcellulose to the reactor, then add 25mL of water to the reactor, stir and heat to 60℃ for gelatinization for 20min, add 10g of 2-acrylamido-2-methylpropanesulfonic acid, Stir 30g sodium acrylate aqueous solution uniformly, add 0.4g potassium persulfate initiator and 0.010g N,N-methylenebisacrylamide crosslinking agent in sequence, react at 70°C for 2.5 hours, and wash twice with ethanol and distilled water respectively. Dry, crush and granulate to obtain a white powder product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com