Sulfonate betaine type acrylamide copolymer oil displacement agent and synthesis method thereof

A technology of methacrylamide and betaine, which is applied in the direction of sulfonate preparation, chemical instruments and methods, and drilling compositions, etc., can solve the problems of low yield, complex preparation process of oil displacement agent, and high cost. Achieve the effects of simple preparation process, enhanced oil recovery and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Synthesis of sodium 3-(3-methylacrylamido-1-dimethylaminopropyl)-2-hydroxypropyl sulfonate

[0044] (1) Add 0.12mol sodium bisulfite and 100mL deionized water into a 250mL three-necked flask, stir to dissolve;

[0045] (2) Heat to 85°C, slowly add 0.1 mol epichlorohydrin dropwise, and react for 3.5 hours after the dropwise addition is complete;

[0046] (3) After the reaction, cool to room temperature, filter with suction, and recrystallize the solid with deionized water three times to obtain a white solid of sodium 3-chloro-2-hydroxy-propanesulfonate;

[0047] (4) Dissolve N-dimethylaminopropyl methacrylamide in a 70% ethanol solution, and slowly add dropwise the aqueous solution of sodium 3-chloro-2-hydroxy-propanesulfonate prepared above, N-dimethylamino The molar ratio of propylmethacrylamide to sodium 3-chloro-2-hydroxy-propanesulfonate is 1.2:1;

[0048] (5) Heat to 70°C and react for 6-8 hours;

[0049] (6) After the reaction is completed, cooling, rotary evapor...

Embodiment 2

[0050] Example 2: Structural characterization of sodium 3-(3-methylacrylamido-1-dimethylaminopropyl)-2-hydroxypropyl sulfonate

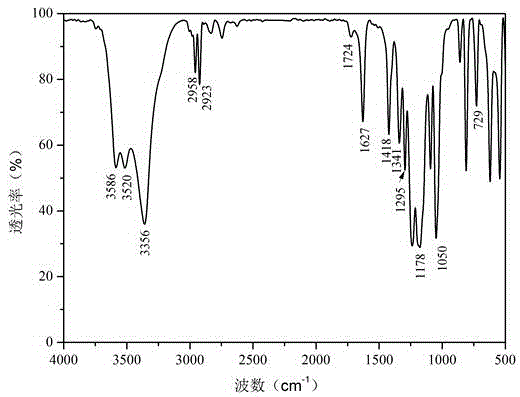

[0051] The infrared spectrum of 3-(3-methylacrylamido-1-dimethylaminopropyl)-2-hydroxypropyl sulfonate synthesized by implementation example 1 is as follows figure 1 Shown. by figure 1 It can be seen that 3586cm -1 And 3520cm -1 O-H stretching vibration peak at the place; 3356cm -1 Amide N-H stretching vibration peak at the place; 2958cm -1 And 2923cm -1 At -CH 3 And -CH 2 Stretching vibration peak; 1724cm -1 Where is the amide C=O stretching vibration peak; 1627cm -1 C=C stretching vibration peak; 1418cm -1 And 1341cm -1 At -CH 3 And -CH 2 Flexural vibration peak; 1295cm -1 C-N stretching vibration peak in ammonium; 1178cm -1 And 1050cm -1 At-SO 3 - S=O, S-O in - Stretching vibration peak; 729cm -1 At -CH 2 -Stretching vibration peak.

Embodiment 3

[0052] Implementation example 3: Synthesis of copolymer oil-displacing agent AM / DMEA / MPAS

[0053] (1) Put AA, MPAS, and DMEA into a 250 mL three-neck flask according to the monomer mass feed ratio, add an appropriate amount of deionized water, and adjust the total monomer concentration to 25 wt%. Under the condition of 300-400rpm, stir for 10min to make the system evenly dispersed;

[0054] (2) Blow in nitrogen at 40°C for 30 minutes, then add the initiators ammonium persulfate and sodium bisulfite (the molar ratio of ammonium persulfate and sodium bisulfite is 1:1), and the amount of initiator added is the total monomer 0.4% of quality;

[0055] (3) At a reaction temperature of 40°C, nitrogen gas is introduced for 10-20 minutes, and the reaction is continued for 8 hours;

[0056] (4) After the reaction is completed, the reaction product is washed three times with absolute ethanol, pulverized, and dried to prepare the AM / DMEA / MPAS terpolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com