Lubricating oil

A technology for lubricating oil and base oil, applied in the field of lubricating oil, can solve problems such as reducing the performance of lubricating oil, and achieve the effect of improving fuel economy, excellent fuel economy and MRV viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

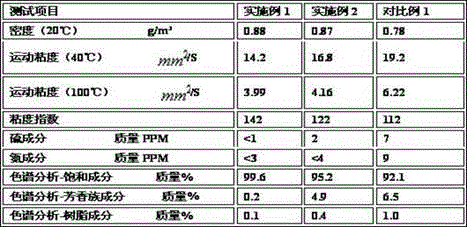

Examples

Embodiment 1

[0022]Lubricating oil, including the following substances in parts by weight: 0.01-0.5 parts of paraffin, 0.0-1.0 parts of molybdenum dialkyldithiophosphate, 0.1-1 part of polyurethane, 0.02-1.25 parts of modified polyurea, low molecular weight polyethylene 3-5 parts of wax, 1-50 parts of thionyl octyl zinc salt, 20-67 parts of petroleum ether, 1-20 parts of absolute ethanol, 3-15 parts of xylene, 3-56 parts of dichloromethane, benzyl alcohol 1-20 parts, 3-12 parts of n-pentane.

[0023] The production method of this lubricating oil comprises the following steps:

[0024] 1) Heat the mixture of base oil and petroleum ether to 50°C, then add paraffin wax and oxymolybdenum dithiophosphate into petroleum ether, stir well to form mixture I;

[0025] 2) Add terpolymer, modified polyurea, low molecular weight polyethylene wax, thionyl octyl zinc salt, dehydrated alcohol, xylene, methylene chloride, benzyl alcohol and n-pentane to mixture I successively, add Stir continuously durin...

Embodiment 2

[0029] Lubricating oil, including the following parts by weight: 0.3 parts of paraffin, 0.7 parts of oxymolybdenum dialkyldithiophosphate, 0.5 parts of polyurethane, 1.0 parts of modified polyurea, 4 parts of low molecular weight polyethylene wax, and thiophosphatine 25 parts of base zinc salt, 50 parts of petroleum ether, 10 parts of absolute ethanol, 5 parts of xylene, 10 parts of dichloromethane, 10 parts of benzyl alcohol, and 10 parts of n-pentane.

[0030] The production method of this lubricating oil comprises the following steps:

[0031] 1) Heat the mixture of base oil and petroleum ether to 60°C, then add paraffin and molybdenum dialkyl dithiophosphate into petroleum ether, stir well to form mixture I;

[0032] 2) Add terpolymer, modified polyurea, low molecular weight polyethylene wax, thionyl octyl zinc salt, absolute ethanol, xylene, methylene chloride, benzyl alcohol and n-pentane to mixture I in sequence, add Stir continuously during the process to form mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com