Juglans sigillata oil expression production device

A production device and a technology for iron walnut, which are applied in the directions of fat oil/fat production, fat production, etc., can solve the problems of inability to realize automation, increase production processes, increase production costs, etc. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

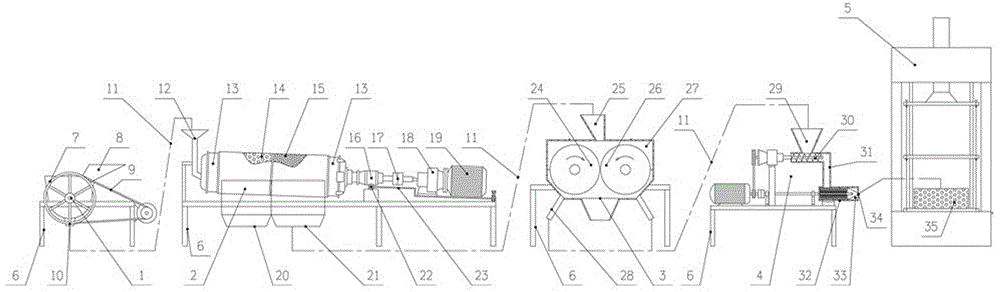

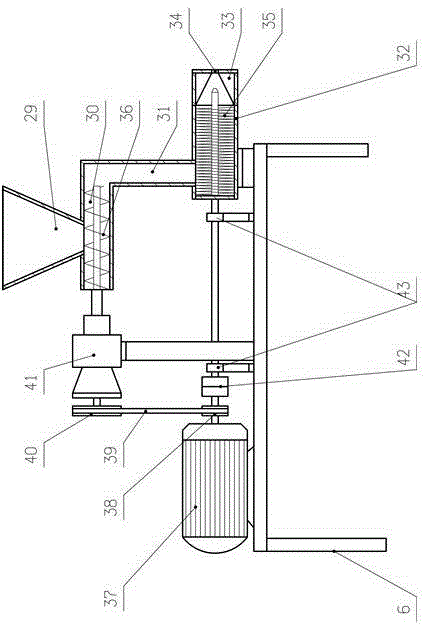

[0016] like figure 1 and figure 2 As shown, an iron walnut oil pressing production device includes a crusher, a screening machine, a shell kernel separator and a hydraulic oil press arranged in sequence along the horizontal direction. The feed port of the screening machine is connected. The screening machine is composed of a frame, a coarse screen drum, a fine screen drum and a transmission device. The coarse screen drum and the fine screen drum are connected to form a downwardly inclined cylinder. , the horizontal inclination angle between the cylinder body and the frame is 10 degrees, and there are multiple steel wool balls used to separate shells and kernels in the coarse screen drum and fine screen drum. The steel wire balls are radial. There is a discharge port for collecting crushed walnut kernels. The diameter of the hole on the outer wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com