Heat-storage steam generating device

A steam generating device and heat storage technology, applied in the field of heat storage equipment, can solve the problems of inability to meet the demand of steam temperature, large environmental pollution, small heat storage, etc., and achieve the effects of simple structure, low cost, and alleviating power consumption pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

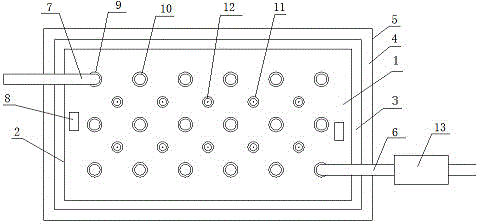

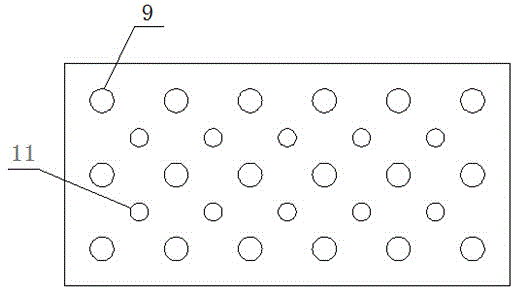

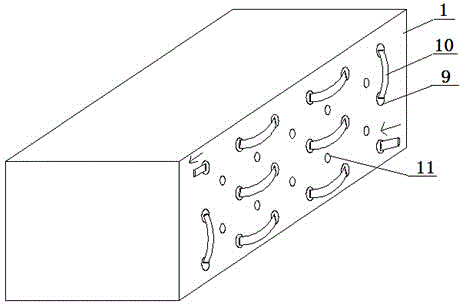

[0026] like Figure 1-4 As shown, a thermal storage steam generating device, the thermal storage steam generating device is a closed cubic structure, mainly including a graphite block 1, a wrapping layer 2, an airgel layer 3, an insulating layer 4, a casing 5, and a water inlet pipe 6. Steam outlet pipe 7, temperature sensing probe 8, the graphite block 1 is arranged in the center of the heat storage steam generating device, and its outside is wrapped with a layer of wrapping layer 2, and the wrapping layer 2 is coated with an airgel layer 3. The gel layer 3 is provided with a thermal insulation layer 4, and the thermal insulation layer 4 is provided with a shell 5, so that the graphite block 1 is wrapped layer by layer to form a heat storage steam generator with good thermal insulation. The graphite block 1 is evenly provided with heating coil jacks 9, and a row of electric heating rod jacks 11 is set at the midpoint between every two rows of heating coil jacks 9, and the ele...

Embodiment 2

[0029] like Figure 1-4 As shown, a thermal storage steam generating device, the thermal storage steam generating device is a closed cubic structure, mainly including a graphite block 1, a wrapping layer 2, an airgel layer 3, an insulating layer 4, a casing 5, and a water inlet pipe 6. Steam outlet pipe 7, temperature sensing probe 8, the graphite block 1 is arranged in the center of the heat storage steam generating device, and its outside is wrapped with a layer of wrapping layer 2, and the gap between the wrapping layer 2 and the graphite block 1 is filled with graphite Powder, can reduce the loss of heat energy. The wrapping layer 2 is coated with an airgel layer 3, and the airgel layer 3 is provided with an insulation layer 4. The insulation layer 4 is glass wool with a thickness of 10 cm, so that the thermal insulation effect of the heat storage steam generator is good. Reduce heat loss. A shell 5 is arranged outside the heat insulating layer 4 .

[0030] The graphite...

Embodiment 3

[0035] like Figure 1-4 As shown, a thermal storage steam generating device, the thermal storage steam generating device is a closed cubic structure, mainly including a graphite block 1, a wrapping layer 2, an airgel layer 3, an insulating layer 4, a casing 5, and a water inlet pipe 6. Steam outlet pipe 7, temperature sensing probe 8, the graphite block 1 is arranged in the center of the heat storage steam generating device, and its outside is wrapped with a layer of wrapping layer 2, and the gap between the wrapping layer 2 and the graphite block 1 is filled with graphite Powder, can reduce the loss of heat energy. The wrapping layer 2 is coated with an airgel layer 3, and the airgel layer 3 is provided with an insulation layer 4. The insulation layer 4 is glass wool with a thickness of 10 cm, so that the thermal insulation effect of the heat storage steam generator is good. Reduce heat loss. A shell 5 is arranged outside the heat insulating layer 4 .

[0036] The graphite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com