A kind of graphene material for hot compress material and preparation method thereof

A technology of graphene and graphene layers, applied in phototherapy, radiotherapy, treatment, etc., can solve problems such as poor structural stability and decreased electrothermal conversion effect, achieve reinforcement and repair effects, improve interface affinity, and good The effect of adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

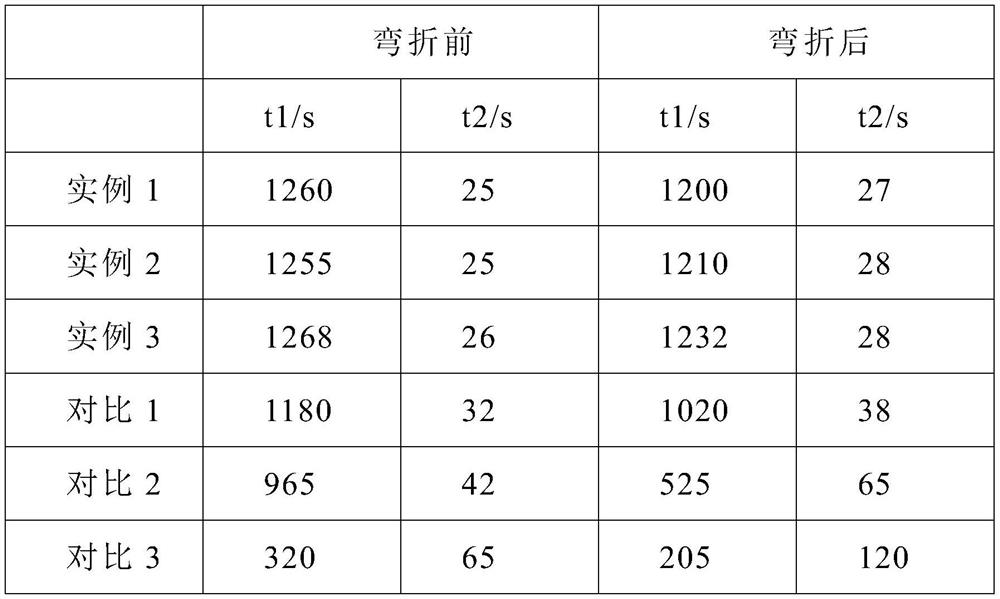

Examples

Embodiment 1

[0036] Pretreatment of graphene oxide:

[0037] Dry the reactor, and then add graphene oxide and toluene diisocyanate into the reactor, the mass ratio of graphene oxide and toluene diisocyanate is 1:5, and then under nitrogen protection, at a temperature of 75°C and a rotational speed of Under the condition of 300r / min, heat and stir for 3 hours, filter, collect the filter cake, and dry at 105°C to constant weight to obtain pretreated graphene oxide;

[0038] Preparation of graphene:

[0039] After mixing graphene oxide and hydrazine hydrate at a mass ratio of 1:5, under the protection of an inert gas at a temperature of 75°C, heat and stir for reaction, then filter and dry to obtain reduced graphene; In terms of parts, take 30 parts of reduced graphene, 80 parts of absolute ethanol, 8 parts of fatty acid, and 3 parts of tetraethyl orthosilicate in sequence. First, ultrasonically disperse the reduced graphene in absolute ethanol at a frequency of 60 kHz, and then add fatty ac...

Embodiment 2

[0043] Pretreatment of graphene oxide:

[0044]Dry the reactor, and then add graphene oxide and toluene diisocyanate into the reactor, the mass ratio of graphene oxide and toluene diisocyanate is 1:7, and then under nitrogen protection, at a temperature of 78°C and a rotational speed of Under the condition of 500r / min, after heating and stirring for 4 hours, filter, collect the filter cake, and dry at a temperature of 108°C to constant weight to obtain pretreated graphene oxide;

[0045] Preparation of graphene:

[0046] After mixing graphene oxide and hydrazine hydrate at a mass ratio of 1:8, under the protection of an inert gas at a temperature of 77°C, heat and stir to react, then filter and dry to obtain reduced graphene; In terms of parts, take 35 parts of reduced graphene, 120 parts of absolute ethanol, 9 parts of fatty acid, and 4 parts of ethyl orthosilicate in sequence. First, ultrasonically disperse the reduced graphene in absolute ethanol at a frequency of 70 kHz, ...

Embodiment 3

[0050] Pretreatment of graphene oxide:

[0051] Dry the reactor, and then add graphene oxide and toluene diisocyanate into the reactor, the mass ratio of graphene oxide and toluene diisocyanate is 1:10, and then under nitrogen protection, at a temperature of 85°C and a rotational speed of Under the condition of 600r / min, after heating and stirring for 5 hours, filter, collect the filter cake, and dry at a temperature of 110°C to constant weight to obtain pretreated graphene oxide;

[0052] Preparation of graphene:

[0053] After mixing graphene oxide and hydrazine hydrate at a mass ratio of 1:10, under the protection of an inert gas at a temperature of 85°C, heat and stir to react, then filter and dry to obtain reduced graphene; In terms of parts, take 40 parts of reduced graphene, 150 parts of absolute ethanol, 10 parts of fatty acid, and 5 parts of ethyl orthosilicate in sequence. First, ultrasonically disperse the reduced graphene in absolute ethanol at a frequency of 80 k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com