Fuel-gas-catalyzing flameless near-infrared direct heating porous medium combustor

A technology of porous media and gas catalysis, applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of uneven distribution of heating temperature, uneven distribution of premixed gas, high emission of combustion pollutants, and achieve surface temperature Stable, less exhaust, high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

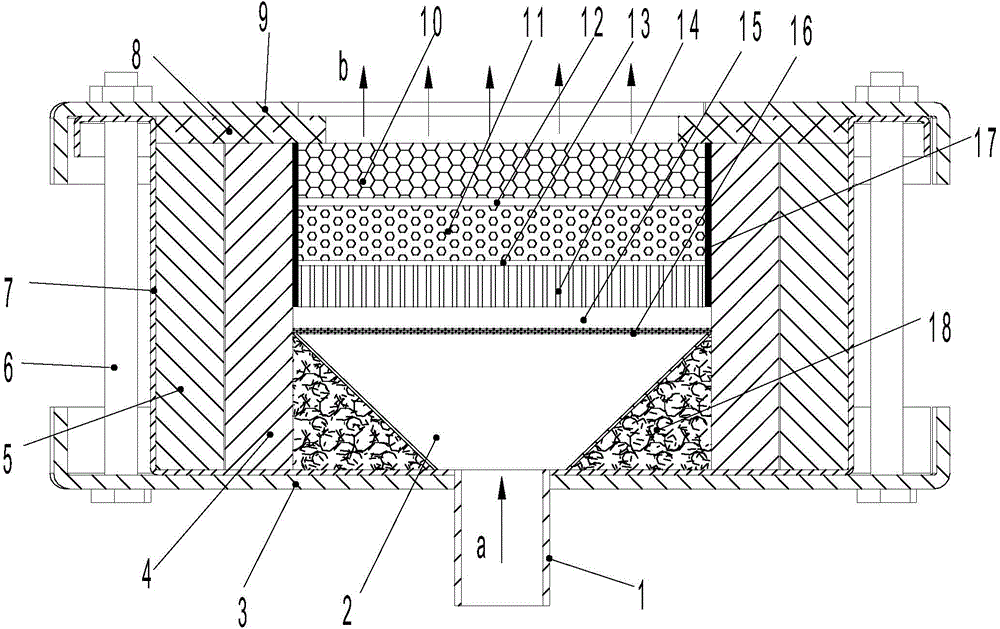

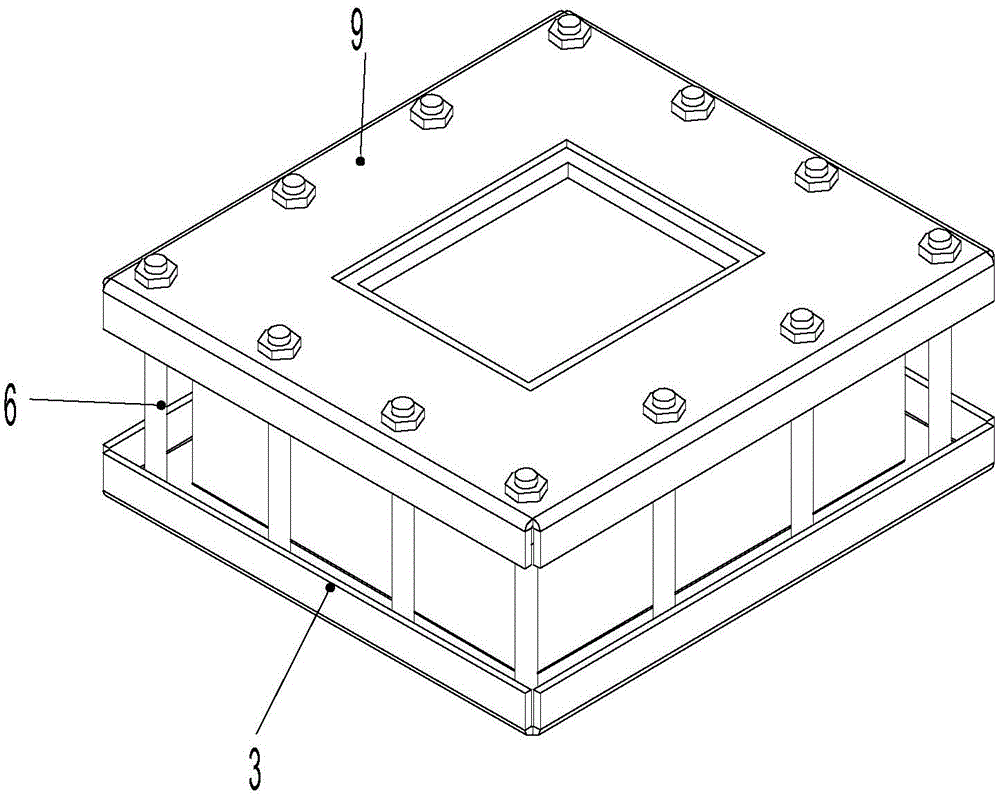

[0048] A gas catalytic flameless near-infrared direct heating porous media burner (see figure 1), including a burner body 7, an insulating layer 5, and a refractory brick layer 4. The refractory brick layer 4 is located in the burner body 7, and the insulating layer 5 is located between the refractory brick layer 4 and the burner body 7. The described The refractory brick layer 4 is sequentially provided with a premixed gas diffusion chamber 2, a perforated plate 16, a premixed gas pressure equalization chamber 15, a flame-resistant barrier plate 14, and a foam ceramic plate from the bottom to the top. The premixed gas diffusion chamber 2 The bottom of the premixed gas supply pipe 1 is in communication with the premixed gas diffusion chamber 2, and insulation cotton 18 is arranged between the periphery of the premixed gas diffusion chamber 2 and the refractory brick layer 4. Together; the upper end surface of the burner body 7 is also provided with an upper compression plate 9...

Embodiment 2

[0060] A gas catalytic flameless near-infrared direct heating porous media burner, the basic structure of the burner is the same as that of Embodiment 1, the difference is that the porosity of the macroporous ceramic foam plate 10 is 90%, and the pore diameter is 20PPI, the plate thickness is 50mm; the porosity of the small-hole foam ceramic plate 11 is 90%, the pore diameter is 65PPI, and the plate thickness is 50mm; holes, the hole spacing is 20mm; the plate thickness of the perforated plate 16 is 4mm, and the holes with a diameter of 3mm are evenly arranged on the perforated plate 16, and the hole spacing is 20mm; the plate thickness of the upper pressing plate 9 and the burner body 7 are 8mm.

Embodiment 3

[0062] A gas catalytic flameless near-infrared direct heating porous media burner, the basic structure of the burner is the same as that of Embodiment 1, the difference is that the porosity of the macroporous ceramic foam plate 10 is 85%, and the pore diameter is 15PPI, the plate thickness is 30mm; the porosity of the small-hole foam ceramic plate 11 is 85%, the pore diameter is 60PPI, and the plate thickness is 20mm; mm holes, the hole spacing is 10mm; the plate thickness of the perforated plate 16 is 2mm, and the holes with a diameter of 2mm are evenly arranged on the perforated plate 16, and the hole spacing is 10mm; the plate thickness of the upper pressing plate 9 and the burner body 7 are uniform is 5mm.

[0063] As a transformation of the above-mentioned embodiments 1 to 3, the porosity of the macroporous ceramic foam plate 10 is 80-90%, the pore diameter is 10-20PPI, and the plate thickness is 10-50mm; the pores of the small-porous ceramic foam plate 11 The rate is 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com