Preparation method of flexible package material of lithium ion battery

A lithium-ion battery and flexible packaging technology, which is applied in the direction of battery case/cover material, battery, battery case/cover, etc., can solve problems such as high brittleness, insufficient cold stamping performance, and insufficient mechanical properties, so as to achieve smooth surface and avoid thermal stress , to avoid uneven effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

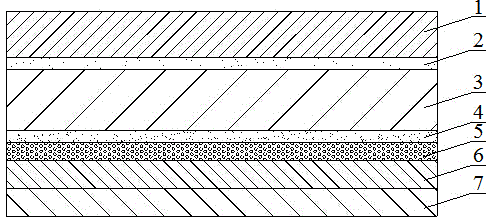

[0039] see figure 1 As shown, the embodiment of the present invention provides a method for preparing a lithium-ion battery flexible packaging material, comprising the following steps:

[0040] S1. Clean the aluminum foil 3, and then perform pretreatment on the cleaned aluminum foil 3. The pretreatment includes forming an inner protective layer 4 on one side of the aluminum foil 3.

[0041] S2. Prepare the heat-sealing layer, the heat-sealing layer includes a cast polyolefin film layer 7 and a modified polyolefin film layer 5 arranged in a laminated manner, the modified polypropylene film layer 5 is arranged on the side of the inner protective layer 4 of the aluminum foil 3, heat The sealing layer is compounded together by co-extrusion at a temperature of 100-150 degrees.

[0042] S3. At a temperature of 140-160 degrees, the heat-sealing layer is heat-laminated on the side of the aluminum foil 3 provided with the inner protective layer 4 through a heat laminating machine to f...

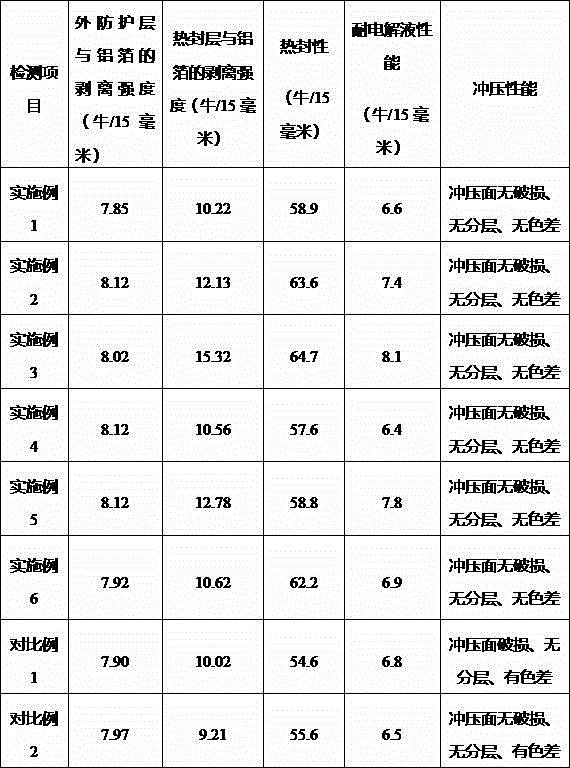

Embodiment 1

[0063] This embodiment provides a method for preparing a lithium-ion battery flexible packaging material, wherein the selected aluminum foil 3 is a soft aluminum foil with a thickness of 40 microns and a width of 650 mm, which specifically includes the following steps:

[0064] Step 101, wash the aluminum foil 3 with water, and then perform pretreatment on the cleaned aluminum foil 3. The pretreatment includes preparing a passivation solution containing trivalent chromium ions. The mass fraction of the trivalent chromium salt in the solution is 0.3%. The aluminum foil 3 is soaked in the prepared trivalent chromium ion solution, and the chromium oxide is deposited on the surface of the aluminum foil 3 after drying, and a thin and dense outer protective layer of chromium oxide is formed on both sides of the aluminum foil 3 respectively. 3 and the inner protective layer 4. The thickness of the inner protective layer 4 is 0.1 micron, and the thickness of the outer protective layer...

Embodiment 2

[0073] This embodiment provides a method for preparing a lithium-ion battery flexible packaging material, wherein the selected aluminum foil 3 is a soft aluminum foil with a thickness of 100 microns and a width of 650 mm, which specifically includes the following steps:

[0074]Step 201, wash the aluminum foil 3 with water, and then perform pretreatment on the cleaned aluminum foil 3. The pretreatment includes preparing a passivation solution containing trivalent chromium ions. The mass fraction of the trivalent chromium salt in the solution is 3.3%. The aluminum foil 3 is soaked in the prepared solution of trivalent chromium ions. After drying, the chromium oxide is deposited on the surface of the aluminum foil 3, and at the same time, a thin and dense outer protective layer 3 of chromium oxide is formed on both sides of the aluminum foil 3. and inner protective layer 4. The thickness of the inner protective layer 4 is 1 micron, and the thickness of the outer protective layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com