Multifunctional transformer used for traction transmission system

A traction drive, traction inverter technology, applied in control systems, electrical energy storage systems, control/regulation systems, etc., can solve problems such as train speed loss, equipment damage, and increase in traction network voltage, to reduce volume and The effect of weight, improving energy utilization, reducing speed loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

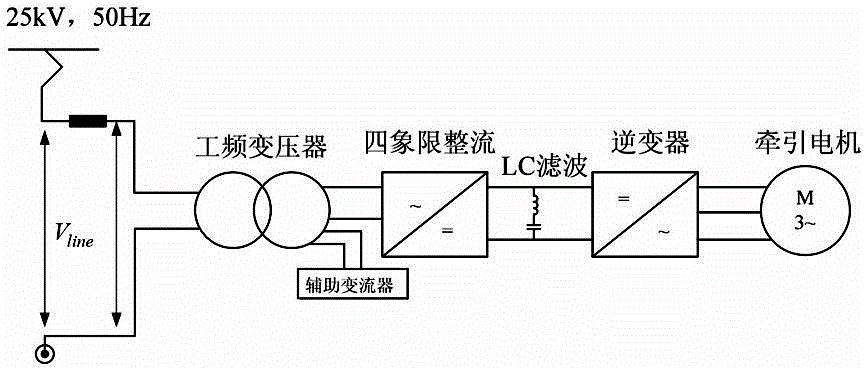

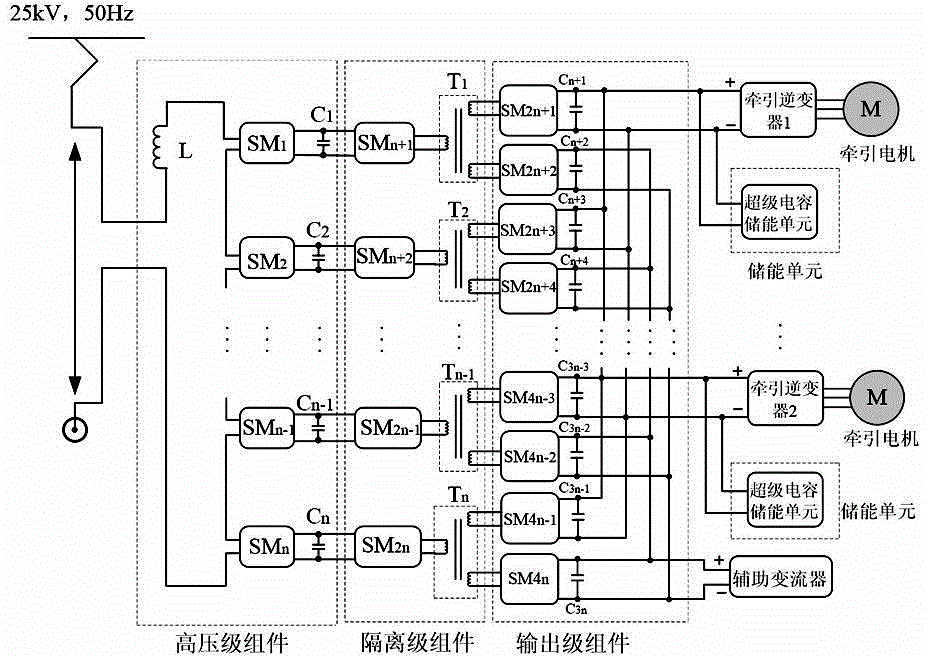

[0032] The multifunctional transformer used for the traction drive system of the present invention is based on the electronic power transformer technology; as figure 2 As shown, taking the specific application of a transformer with two traction motors as an example, the transformer includes:

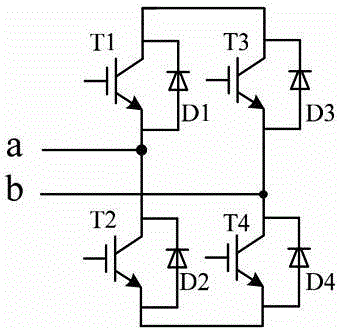

[0033] The high-voltage level components are connected to the railway traction network with an AC voltage of 25kV by connecting the reactance L, and are cascaded by cascading n-level bridge-type power sub-modules (SM1-SMn, Submodule). The circuit diagram of the power sub-module SM is as follows image 3 As shown; each H-bridge is connected in parallel with a capacitor (C1-Cm) of the same capacity, and the capacitor has the function of energy storage and filtering. The H-bridge module converts the AC voltage it bears into a DC voltage across th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com