A preparation method of single-hole hollow polyarabinogalactose-chitosan composite microspheres

A technology of arabinogalactose and composite microspheres, which is applied in the directions of non-active ingredients such as medical preparations, pharmaceutical formulations, and bulk transportation, can solve the problems of large residues, utilization restrictions, waste of biomass energy, etc., and achieves the preparation process. Simple, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

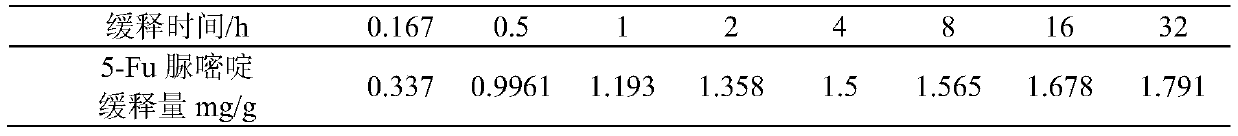

Embodiment 1

[0016] Stir 2.8 mg of the water-soluble drug 5-Fu uracil, 10 mg of polyarabinogalactose, 1.075 g of chitosan, and 10 mL of 1 wt % acetic acid aqueous solution into a transparent mixture and vacuum degassing for 2 hours to obtain drug-loaded microsphere slurry A; Add 2.4g of compound emulsifier (the mass ratio of sodium lauryl sulfate to Tween-80 is 1:1) and 10mL of liquid paraffin and stir at high speed for 1 hour to form O / W emulsion B; Add 190mL of liquid paraffin and continue to stir for 1 hour to form O / W / O emulsion C; use glutaraldehyde to cross-link polyarabinogalactose and chitosan and set it at 40°C for 6 hours, cool and solidify and separate with a separatory funnel The crude microspheres D were obtained from the upper layer of liquid paraffin; the crude product D was dialyzed in distilled water with a dialysis membrane with a molecular weight cut-off of 8000Da; centrifuged at a speed of 4000r / min, washed with hot water for 3 times, and freeze-dried to obtain an averag...

Embodiment 2

[0018] Stir 2.8 mg of the water-soluble drug 5-Fu uracil, 10 mg of polyarabinogalactose, 1.075 g of chitosan, and 10 mL of 1 wt % acetic acid aqueous solution into a transparent mixture and vacuum degassing for 2 hours to obtain drug-loaded microsphere slurry A; Add 2.4g Tween-80 and 10mL liquid paraffin and stir at high speed for 1 hour to form O / W emulsion B; under the condition of 1000r / min high-speed turbulent flow, add 190mL liquid paraffin and continue stirring for 1 hour to form O / W / O emulsion C; Dialdehyde cross-linked polyarabinogalactose and chitosan and set it at 40°C for 6 hours. After cooling and solidifying, the upper layer of liquid paraffin was separated with a separating funnel to obtain crude microspheres D; a dialysis membrane with a molecular weight cut-off of 8000Da was used to The crude product D was dialyzed in distilled water; centrifuged at a speed of 4000r / min, washed three times with hot water, and freeze-dried to obtain single-hole hollow polyarabino...

Embodiment 3

[0020] Stir 2.8 mg of the water-soluble drug 5-Fu uracil, 10 mg of polyarabinogalactose, 1.075 g of chitosan, and 10 mL of 1 wt % acetic acid aqueous solution into a transparent mixture and vacuum degassing for 2 hours to obtain drug-loaded microsphere slurry A; Add 2.4g of polyvinyl alcohol and 10mL of liquid paraffin and stir at high speed for 1 hour to form O / W emulsion B; under the condition of 1000r / min high-speed turbulent flow, add 190mL of liquid paraffin and continue to stir for 1 hour to form O / W / O emulsion C; use glutaraldehyde Cross-link polyarabinogalactose and chitosan and set it at 40°C for 6 hours. After cooling and solidifying, use a separatory funnel to separate the upper liquid paraffin to obtain crude microspheres D; use a dialysis membrane with a molecular weight cut-off of 8000Da in distilled water The crude product D was dialyzed; centrifuged at a speed of 4000r / min, washed three times with hot water, and freeze-dried to obtain single-hole hollow polyarab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com