Porous gold nanowire and manufacturing method and application thereof

A technology of gold nanowires and nanowires, applied in the field of fluorescence-enhanced porous gold nanowires and its preparation, can solve the problems of inability to realize micro-region detection and fluorescence imaging, few fluorescence enhancement sites, large size, etc., and achieve pore size distribution The effects of narrow range, reduced background interference, and uniform fluorescence enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

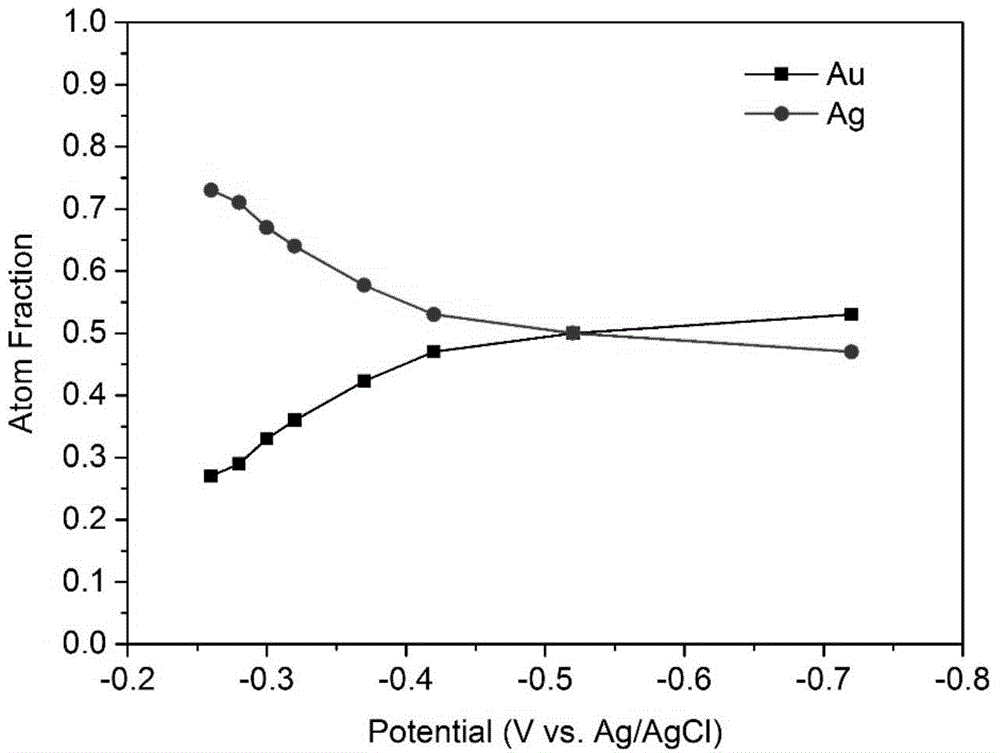

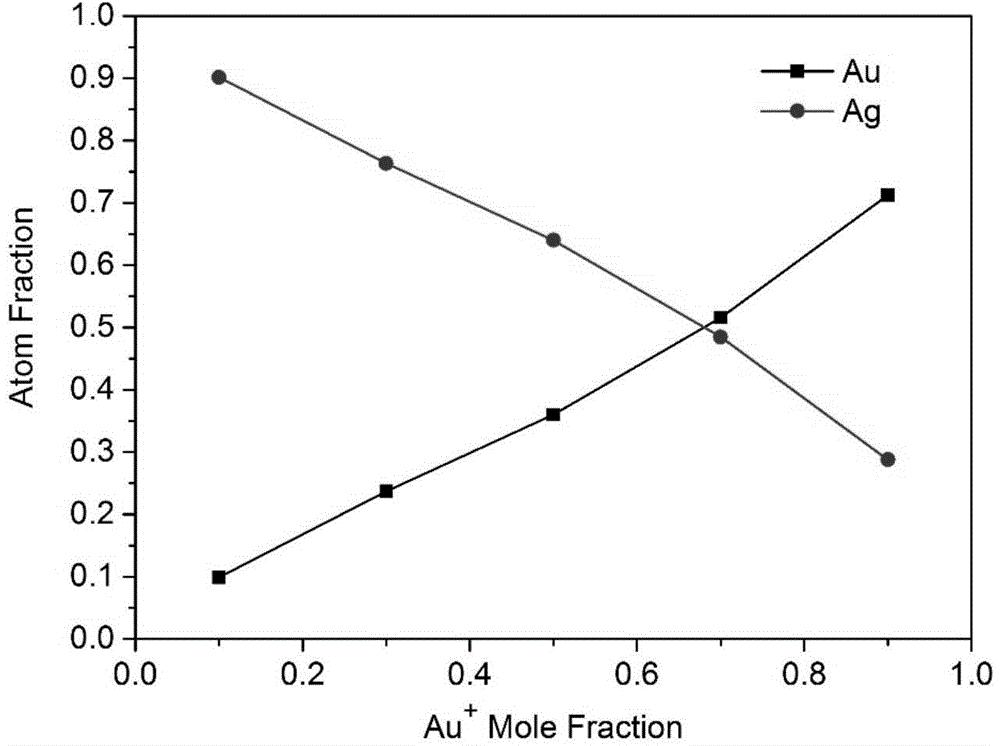

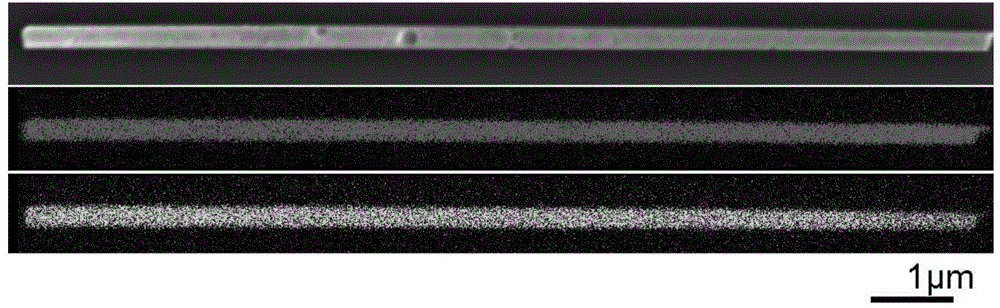

[0062] Au will be obtained 0.36 Ag 0.64 The nanowires were immersed in 65-68w% concentrated nitric acid and corroded for 6 hours. The nitric acid corroded the silver element, and the remaining gold atoms were re-polymerized and arranged to form a three-dimensional continuous nanopore and gold skeleton structure; after the concentrated nitric acid treatment, the Add excess dilute ammonia water; filter and separate the porous gold nanowires, wash with deionized water, disperse in water, and set aside. The SEM characterization images of the prepared porous gold nanowires are as follows: Figure 4 The pore sizes are shown in Table 1.

Embodiment 2-6

[0064] According to the same method as in Example 1, the nitric acid corrosion was carried out, and the corrosion time was changed to 5min, 15min, 1h, 3h, and 11h respectively, and porous gold nanowires with different pore diameters were prepared, and the pore diameters were as shown in Table 1:

[0065] Table 1

[0066] Numbering corrosion time Aperture (nm) Example 1 6h 37-45 Example 2 5min 9-11 Example 3 15min 15-19 Example 4 1h 22-26 Example 5 3h 32-40 Example 6 11h 42-49

[0067] It can be seen from Table 1 that with the prolongation of the nitric acid treatment time, the equivalent size of the pores and skeleton structure gradually increases, and the relationship between the equivalent size of the pores and the skeleton and the nitric acid corrosion time is as follows: Figure 5 shown.

[0068] In addition, the length of the porous gold nanowire in Example 1 is 10 μm and the diameter is 250 nm; the length of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com