A plasma wire cutting method and cutting device

A plasma and wire cutting technology, used in attachments, electric processing equipment, metal processing equipment, etc., can solve the problems of small thickness, inability to achieve high-speed cutting, inability to complete deep cutting operations, etc., to achieve convenient movement and stable working conditions reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

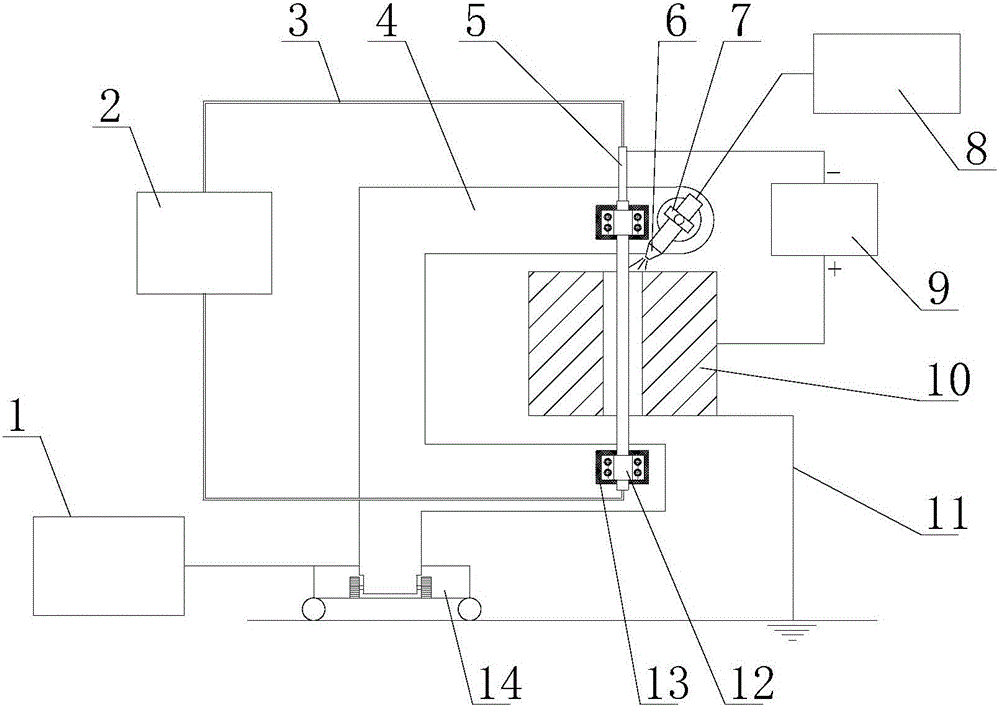

[0024] The specific embodiments of the present invention will be further described below in conjunction with the drawings:

[0025] A plasma wire cutting method. The plasma cutting wire 5 with a diameter of 2-10mm is connected to the negative electrode of the arc controller 9, and the metal piece 10 to be cut is connected to the positive electrode of the arc controller 9. The arc ignition voltage is 2000-4000V, and the holding voltage is 100-200V. A high-temperature plasma arc is pulled between the plasma cutting line 5 and the metal piece 10 to be cut, and bombards the metal piece 10 to be cut to partially melt or even burn; at the same time, gas is blown in through the gas nozzle 6 to remove the molten metal, and the plasma cutting line 5 presses The preset route moves and the process of melting and removing metal is continuously performed to realize the cutting of the metal piece 10 to be cut.

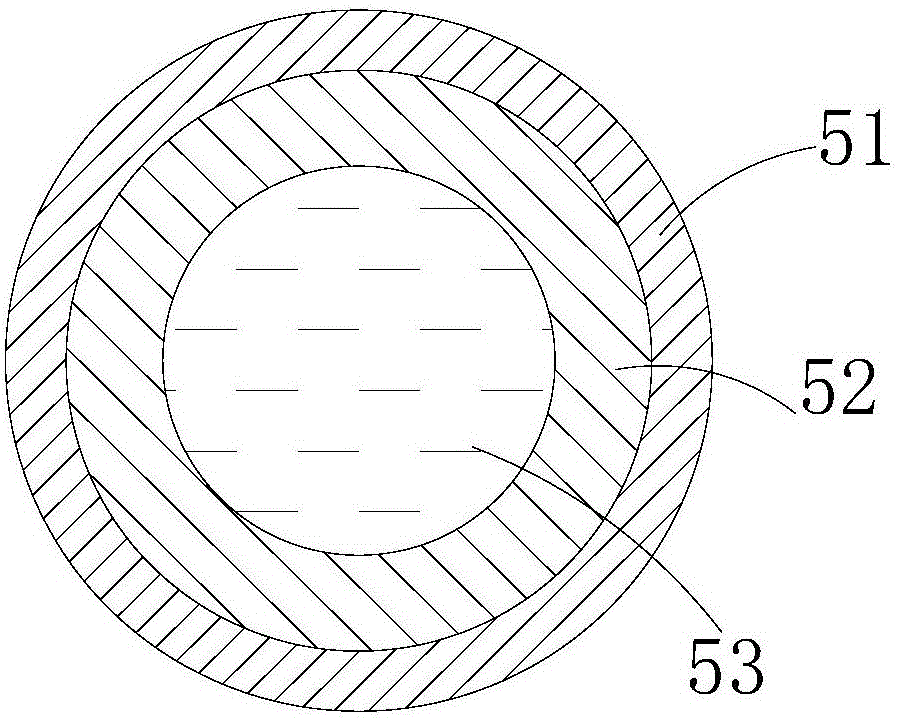

[0026] The plasma cutting line 5 is an electrode wire or a composite electrode sleev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com