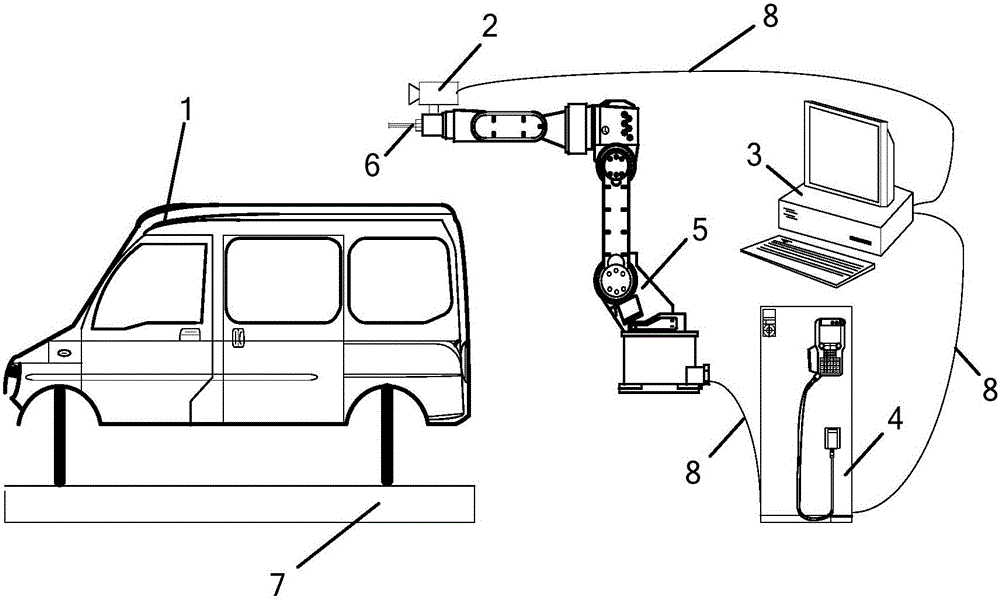

Car body-in-white welding spot positioning method and device based on robot visual servo

A technology of robot vision and positioning method, applied in auxiliary devices, vehicle parts, welding equipment, etc., can solve the problems that solder joints cannot be fully inspected, affect the production capacity of automobiles, and the inspection efficiency is not very high, so as to reduce manual operations, The effect of reducing production costs and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings and examples.

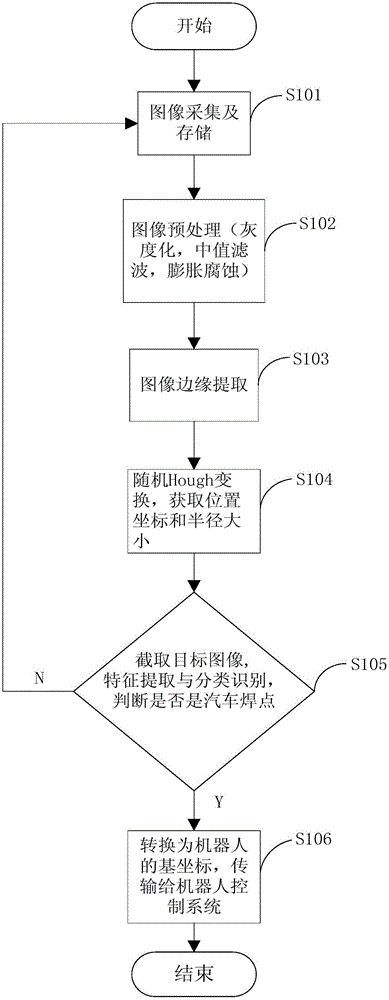

[0039] like figure 1 As shown, the positioning method in this embodiment includes the following steps:

[0040] S101. Acquiring an image of a partial body with welding spots of the body-in-white through the image acquisition unit, storing the acquired image in the storage unit, and reading the image from the storage unit;

[0041] S102. Perform image preprocessing on the collected color image, successively perform image grayscale, median filter, expansion and corrosion processing on the image, and remove the interference of factors such as rust and scratches on the white body of the car;

[0042] S103. Perform image edge extraction on the preprocessed image to obtain an ideal edge detection image;

[0043] S104, using random Hough transform to identify and locate the position coordinates and radius of the welding spot or circular hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com