Manganese Sand Fluidized Bed-Ultrafiltration-UV Disinfection Groundwater Iron and Manganese Removal Device

A technology of ultraviolet disinfection and fluidized bed, which is applied in the field of water treatment, can solve problems such as interference with manganese removal effect, complex process flow, membrane clogging, etc., and achieve high utilization rate of manganese sand, high removal efficiency, and prevention of membrane fouling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

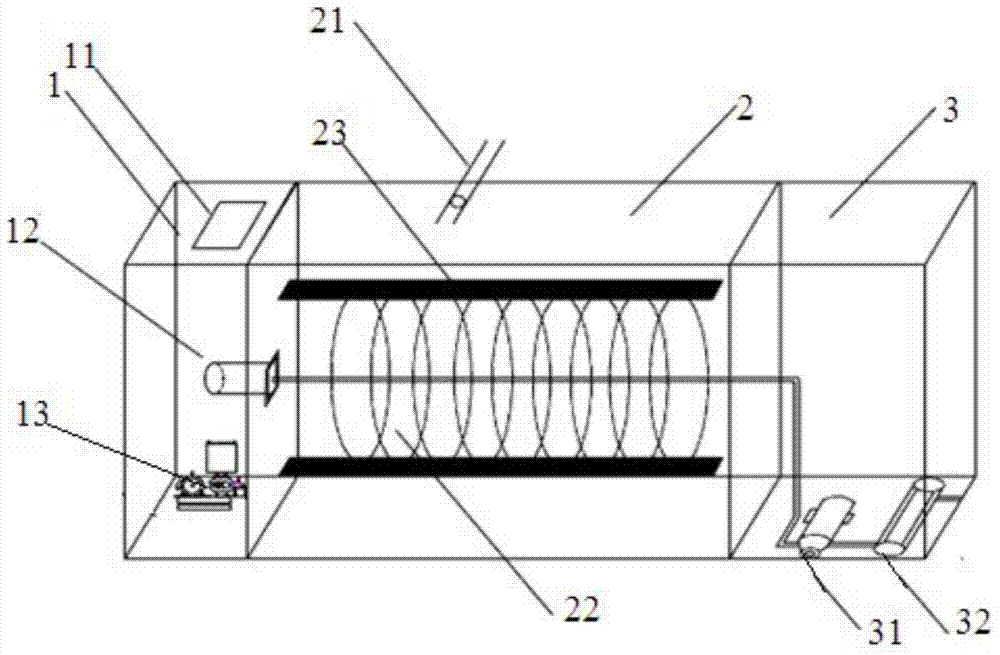

[0028] Such as figure 1 As shown, a manganese sand fluidized bed-ultrafiltration-ultraviolet disinfection groundwater removal iron and manganese device is disclosed in this embodiment, which includes: control room 1, manganese sand fluidized bed-ultrafiltration room 2 and ultraviolet disinfection room 3 , control the above-mentioned manganese sand fluidized bed-ultrafiltration chamber 2 and the ultraviolet disinfection chamber 3 to carry out water treatment through the control device 11 in the above-mentioned control room 1, between the above-mentioned manganese sand fluidized bed-ultrafiltration chamber 2 and the ultraviolet disinfection chamber 3 Connected by tubing.

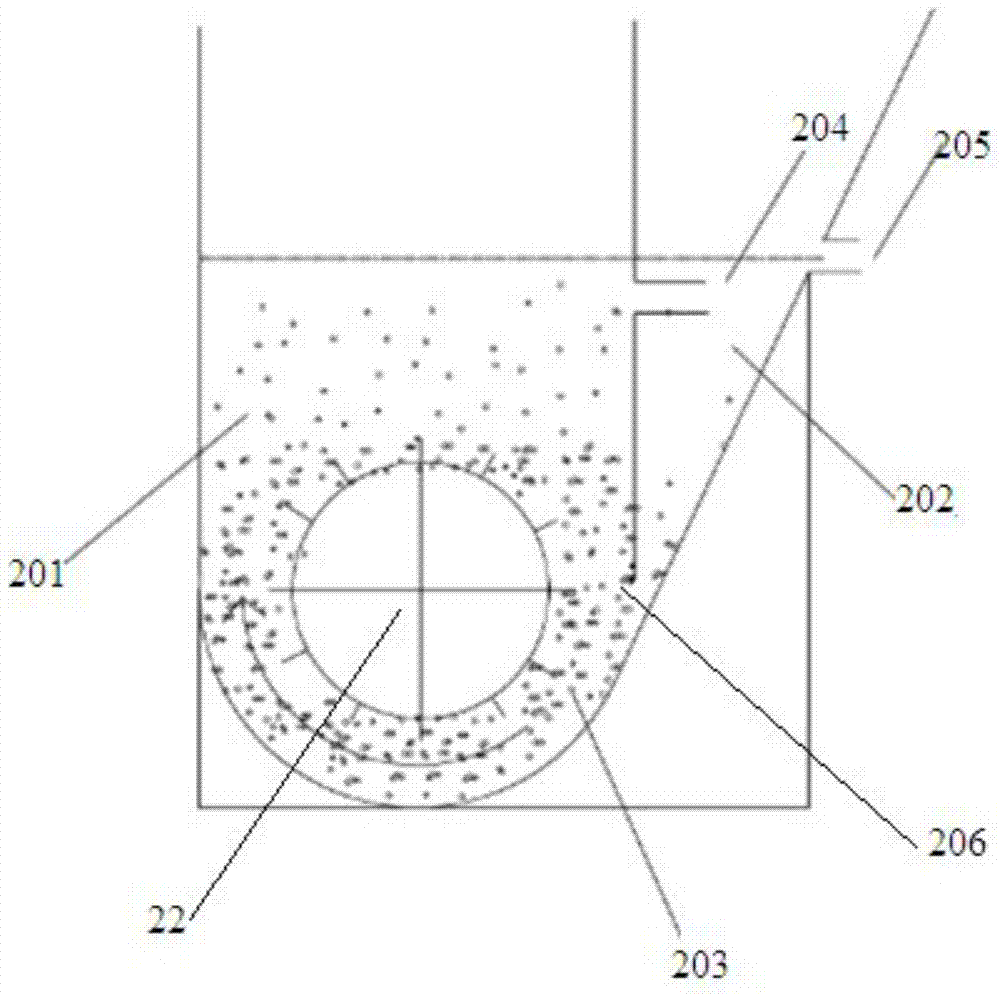

[0029] Above-mentioned manganese sand fluidized bed-ultrafiltration chamber 2 is provided with water inlet pipe 21, and above-mentioned manganese sand fluidized bed-ultrafiltration chamber 2 is provided with rotary membrane turntable 22 and agitator 23, through above-mentioned rotary membrane turntable 22 and ...

Embodiment 2

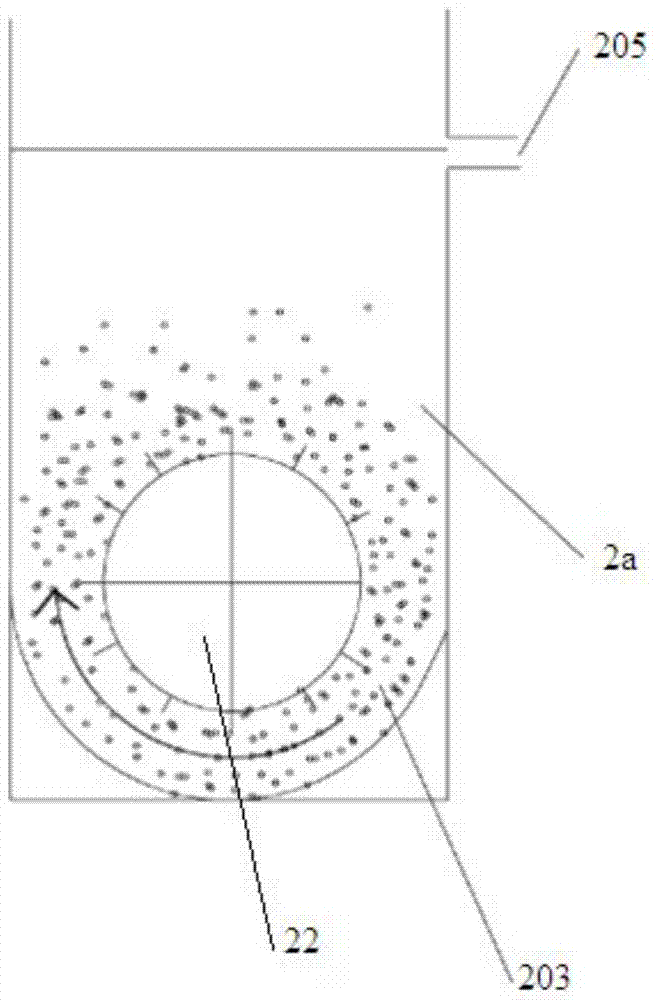

[0037] The difference between the sand fluidized bed-ultrafiltration-ultraviolet disinfection groundwater deferromanganese device in embodiment 2 and the device in embodiment 1 is: the structure of manganese sand fluidized bed-ultrafiltration chamber is different, as image 3 Shown in, the above-mentioned manganese sand fluidized bed-ultrafiltration chamber is a deep ultrafiltration chamber 2a, the above-mentioned deep ultrafiltration chamber 2a is provided with the above-mentioned rotary membrane turntable 22 and manganese sand 203, the upper part of the above-mentioned deep ultrafiltration chamber One side of the suspension is provided with a suspended matter discharge port 205.

[0038] After the fluidized manganese sand in the above-mentioned deep ultrafiltration chamber 2a contacts and reacts with the groundwater containing iron and manganese for a period of time, by setting a high liquid level in the deep ultrafiltration chamber 2a, the manganese sand is precipitated, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com