Preparation method for nano-crystallization low-alloy heat-resistant high-strength steel mould

A low-alloy steel and nano-technology, which is applied in the field of preparation of nano-alloy low-alloy heat-resistant and high-strength steel molds, can solve the problems of inability to withstand high-speed loads, shallow compound layer depth, and inability to withstand heavy loads, and achieves heat resistance and Improved corrosion resistance, reduced types, and increased thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

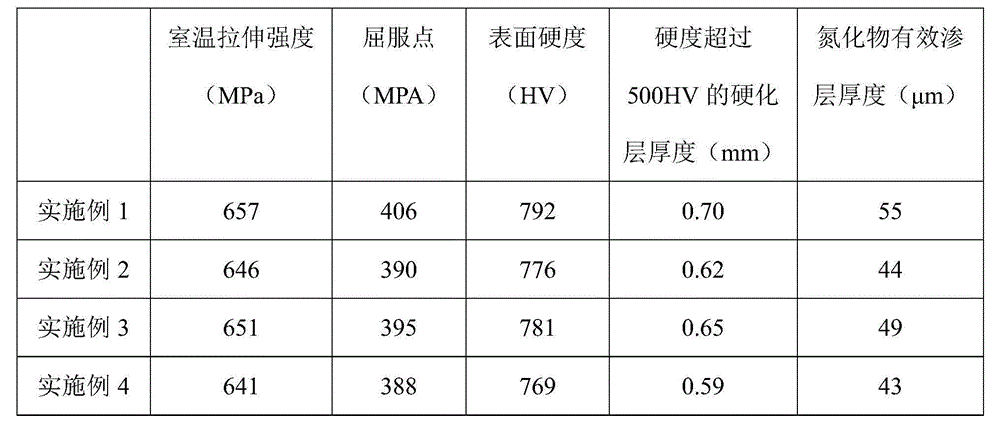

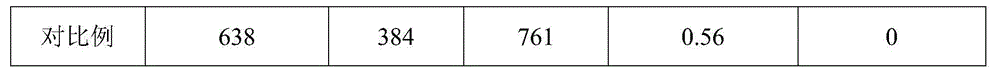

Embodiment 1

[0032] Prepare the nano-sized low-alloy heat-resistant high-strength steel mold of embodiment 1 according to the following steps:

[0033] (1) In terms of weight percentage, prepare low alloy steel with the following components: C 0.09, Cr 1.45, Si 0.30, Mn 0.33, Mo 0.17, Ni 0.15, Nb 0.05, V 0.15, Ti 0.0015, P 0.002, S 0.002, the balance is Fe and unavoidable impurities;

[0034] (11) Smelting and pouring: Carry out the electric arc furnace primary smelting, ladle RH treatment and LF treatment in sequence, and control the molten steel to meet the defined chemical composition before pouring. During the ladle refining, argon blowing is carried out at a pressure above 3 atm for at least 5 minutes to effectively Facilitate the floating and removal of impurities;

[0035] (12) Rolling: including soaking treatment, rolling and cooling, wherein soaking treatment is soaking in a heating furnace at 1150°C for about 5 hours, the starting temperature of rolling is 1000°C, the final rollin...

Embodiment 2

[0047] According to the method described in Example 1, but the base salt described in the step (32) is the following components by weight: 100 parts of potassium cyanate, Ce 2 CO 3 3 parts, ZrO 2 3 copies. The nano-sized low-alloy heat-resistant high-strength steel mold of Example 2 was obtained.

Embodiment 3

[0049] According to the method described in Example 1, but the base salt described in the step (32) is the following components by weight: 100 parts of potassium cyanate, Ce 2 CO 3 3 parts, CeO 2 3 copies. The nano-sized low-alloy heat-resistant high-strength steel mold of Example 3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com