Alkali corrosion resistance high strength steel and production method thereof

A high-strength steel and production method technology, applied in the field of steel materials, can solve the problems that steel is not resistant to alkaline environment corrosion, cannot meet the use strength, etc., to achieve improved corrosion resistance, reduced production costs, and excellent corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

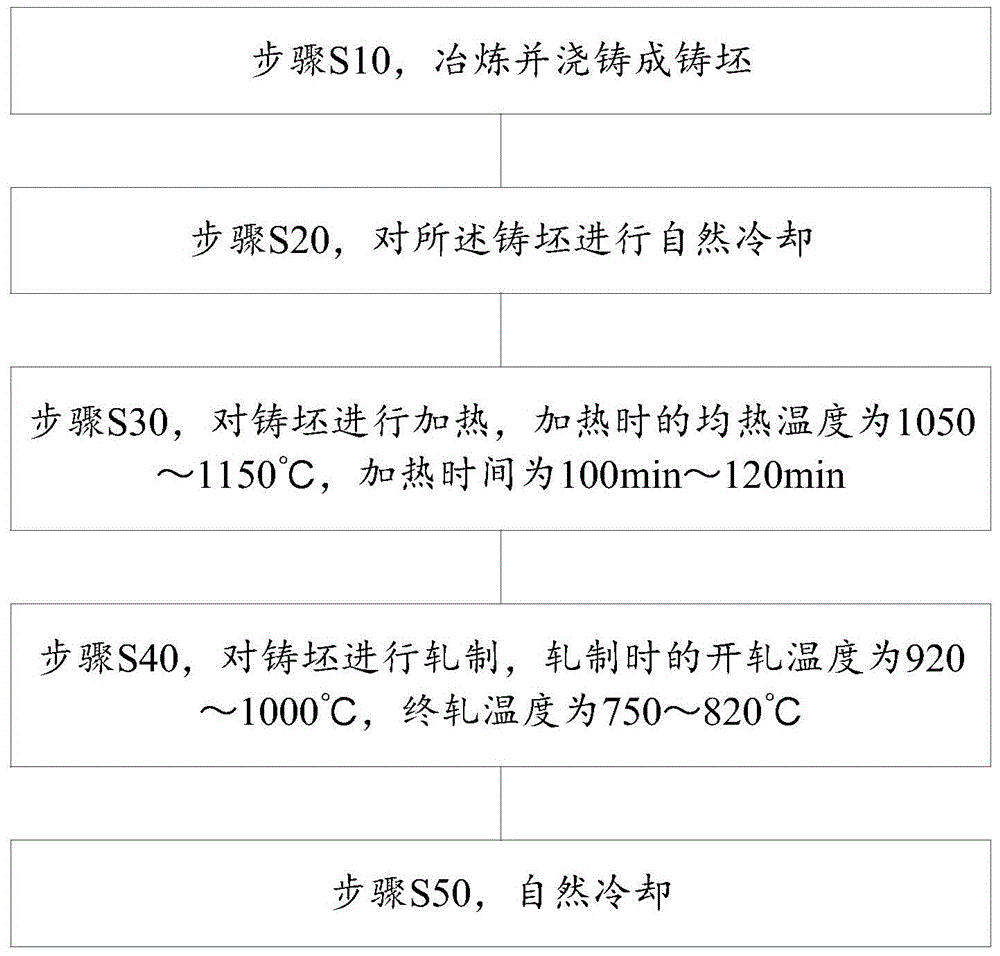

Method used

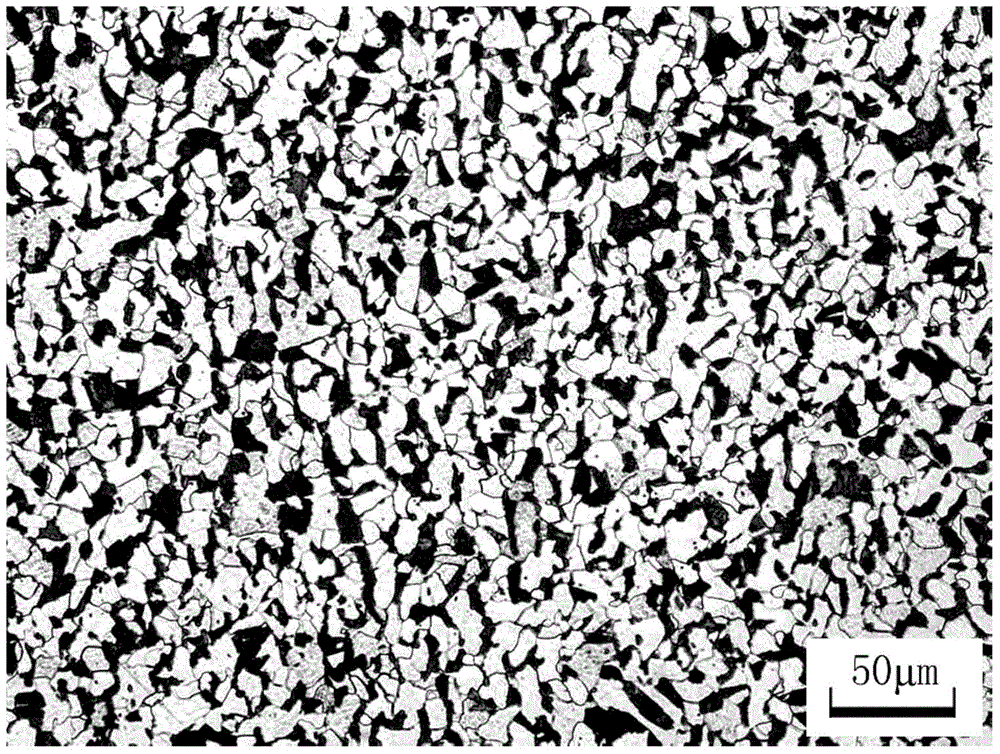

Image

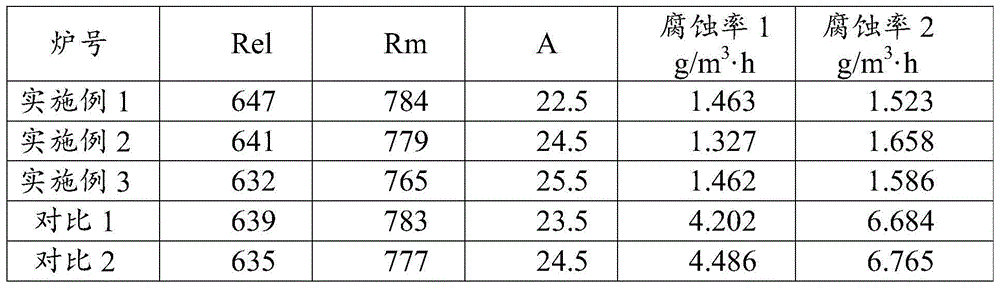

Examples

Embodiment 1

[0079] For the production of steel bars with a specification of Φ12mm, the selected chemical composition is: 0.15%C, 1.27%Mn, 0.73%Si, 0.015%P, 0.011%S, 0.27%Cu, 0.17%Ni, 1.15%Cr, 0.096%V , 0.010% N, 0.0015% B, 0.019% Ti, and the balance is Fe. Continuous rolling process parameters: soaking section temperature: 1050°C, heating time 100min, start rolling temperature: 920°C, final rolling temperature 820°C, free air cooling after going to the cooling bed.

Embodiment 2

[0081] To produce steel bars with a specification of Φ22mm, the selected chemical composition is: 0.18%C, 1.13%Mn, 0.57%Si, 0.008%P, 0.009%S, 0.29%Cu, 0.21%Ni, 1.15%Cr, 0.10%V , 0.0108% N, 0.0021% B, 0.023% Ti, and the balance is Fe. Continuous rolling process parameters: soaking section temperature: 1100°C, heating time 100min, no overheating or overburning, starting rolling temperature: 950°C, final rolling temperature 800°C, free air cooling after going to the cooling bed.

Embodiment 3

[0083] For the production of steel bars with a specification of Φ40mm, the selected chemical components are: 0.20%C, 1.35%Mn, 0.72%Si, 0.007%P, 0.010%S, 0.30%Cu, 0.24%Ni, 1.25%Cr, 0.12%V , 0.0120% N, 0.0027% B, 0.026% Ti, and the balance is Fe. Continuous rolling process parameters: soaking section temperature: 1150°C, heating time 120min, no overheating or overburning, starting rolling temperature: 1000°C, final rolling temperature 750°C, free air cooling after going to the cooling bed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com