Full-seal waterproof system of concrete construction project

A concrete building and fully sealed technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of affecting the waterproof system and waterproof failure, and achieves the effect of strong adhesion and tight combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

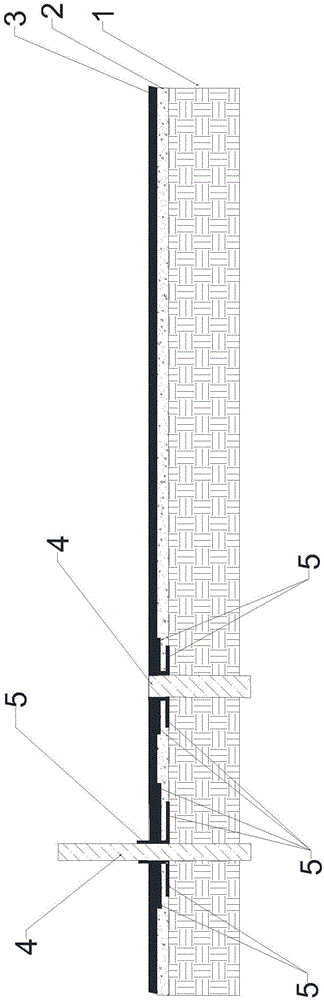

[0042] Such as figure 2 Shown is the basement floor, which has a concrete floor base surface 1, and there are special-shaped parts 4 on the floor, specifically floor drains and water pipes. After construction, a fully sealed waterproof structure is formed, the floor drain and the roots of the pipe roots are coated with a sealing paste waterproof layer 5, and a waterproof coiled material layer 2 and a cement mortar protective layer 3 are sequentially arranged on the concrete base surface 1, and The sealing paste waterproof layer 4 and the waterproof coiled material layer 2 overlap each other. The specific method of lap joint is as follows: a layer of sealing paste waterproof layer 5 is brushed close to the connection transition between the root of the special-shaped part 4 (floor drain, water pipe) and the base surface, and the sealing compound waterproof layer 5 surrounds the root of the special-shaped part 4 The extended radius is 10-50mm, and the vertical turning height is 1...

Embodiment 2

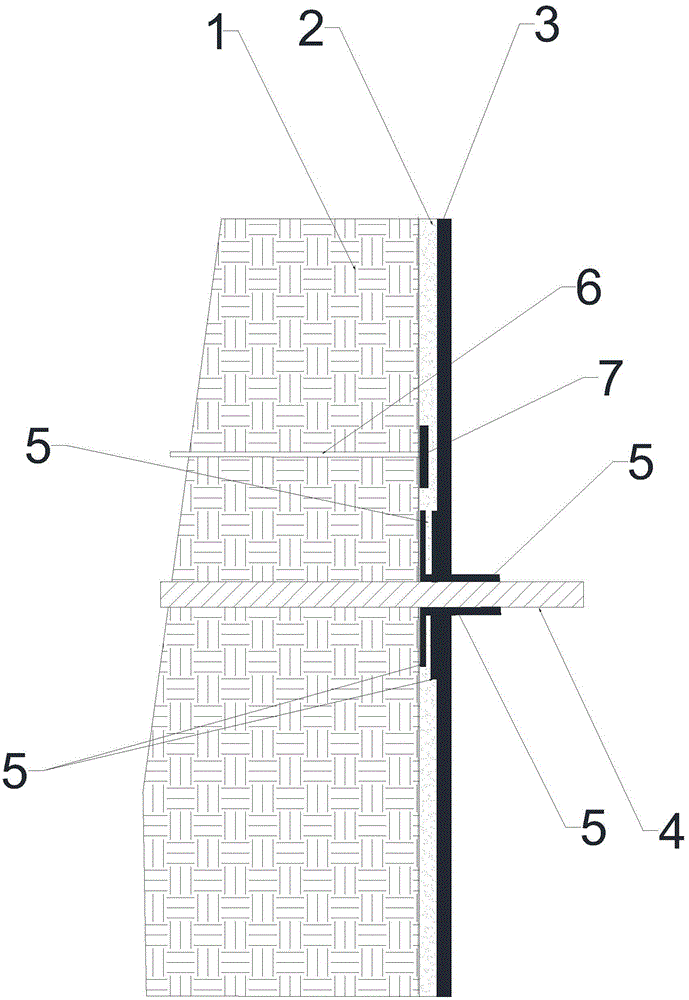

[0047] Such as image 3 As shown, the side wall of the basement has a concrete side wall base surface 1. There are special-shaped parts 4 and gaps 6 on the side walls. After construction, a fully sealed waterproof structure is formed, and the roots of the special-shaped parts 4 are painted The sealing paste waterproof layer 5 is brushed, and the waterproof coiled material layer 2 and the cement mortar protective layer 3 are sequentially arranged on the concrete base surface 1, and the sealing paste waterproof layer 5 and the waterproof coiled material layer 2 overlap each other. The specific method of lap joint is as follows: brush a layer of sealing paste waterproof layer 5 at the connection transition between the special-shaped part 4 and the base surface 1, the sealing paste waterproof layer 5 extends around the root of the node with a radius of 50-100mm, standing The top-turning height is 20-50mm; the waterproof coiled material layer 2 is spread to the edge of the root of th...

Embodiment 3

[0052] Such as Figure 4 Shown is the waterproof structure of a swimming pool in a club. A densely structured concrete self-waterproof layer base surface 1 has been built. The side wall of the swimming pool is provided with a water inlet 41 through the wall, and a water outlet 42 through the wall is provided on the bottom plate. , There are many yin and yang angles formed between the side wall and the bottom plate, and a fully sealed waterproof structure is formed after waterproof construction:

[0053] A waterproof coiled material layer 2 and a cement mortar protective layer 3 are sequentially arranged on the concrete base surface 1, and a waterproof coiled material reinforcement layer 7 is attached to each corner of the swimming pool. The waterproof coiled material reinforcement layer 7 is located in the waterproof coil. Between the material layer 2 and the concrete base surface 1; the width of the waterproof coiled material reinforcement layer is 500-800mm.

[0054] A sealing p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com