A method for capturing carbon dioxide in ore smelting waste gas using lng cold energy

A carbon dioxide and ore technology, applied in the field of carbon dioxide capture, can solve the problems of energy consumption, waste, and failure to recycle LNG cold energy resources, and achieve the effect of reducing carbon emissions and increasing cold energy power generation links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

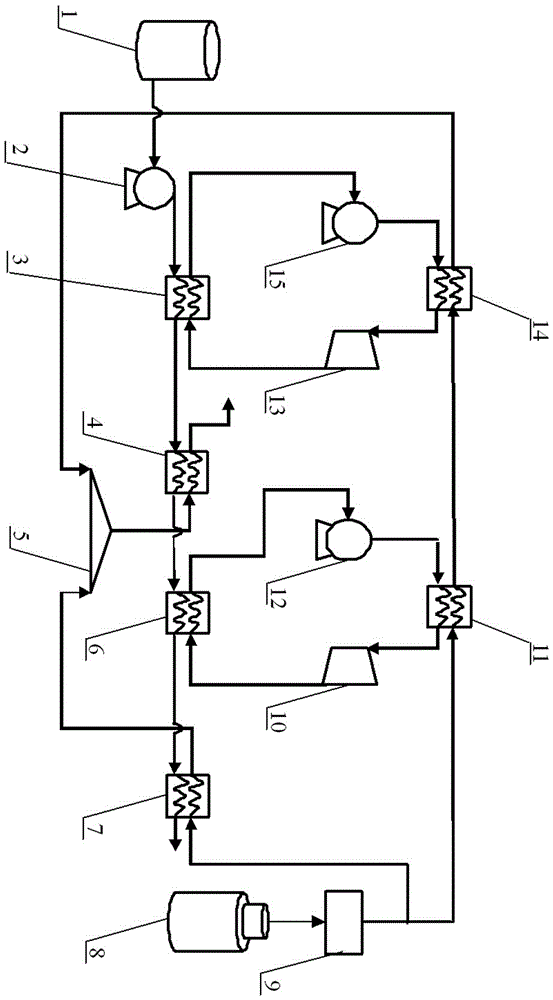

[0030] The invention discloses a method for capturing carbon dioxide in ore smelting exhaust gas utilizing LNG cold energy, which is characterized in that: utilizing LNG cold energy and waste heat of exhaust gas in ore smelting, adopting Rankine cycle cold energy to generate electricity, and simultaneously producing liquid carbon dioxide and Dry ice, which vaporizes natural gas. When the temperature of natural gas rises from -162°C to 20°C, the pressure during the liquefaction of carbon dioxide can be greatly reduced (about 0.15MPa), and at the same time, electricity can be output externally.

[0031] The liquefied natural gas is pumped out from the storage tank and enters the power generation cycle in the Rankine cycle power generation system to provide cooling capacity for the condenser. After the circulating working medium in the power generation system is condensed from gas to supercooled liquid, the temperature of the liquefied natural gas rises. into the front-end heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com