Heating plate and soldering method of IGBT (insulated gate bipolar transistor) module

A heating plate and heating block technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of prolonging the welding time, welding temperature, wasting energy, and accelerating the decomposition of flux, achieving high temperature uniformity and soldering voids The effect of low rate and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

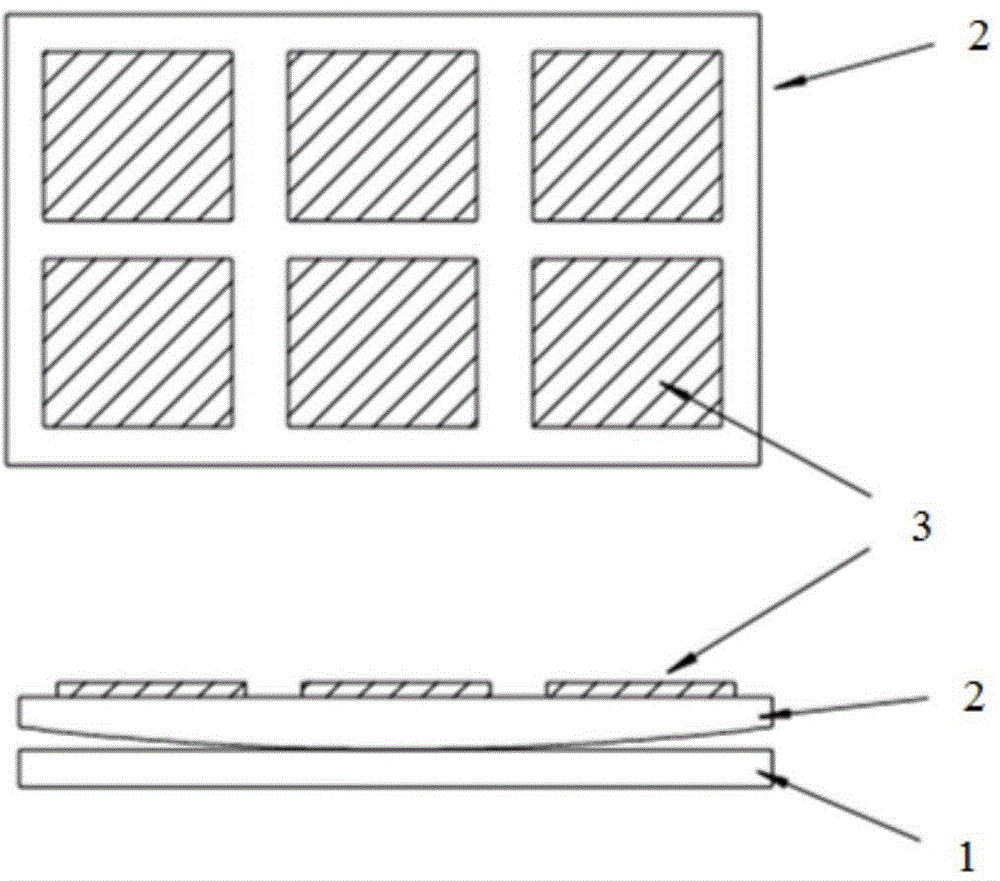

[0036] As mentioned in the background art, in the existing IGBT module reflow soldering process, the heat is conducted to the bottom plate through the heating plate to realize the soldering between the bottom plate and the DBC. Due to the camber of the bottom plate, the temperature of the two DBCs at the center of the bottom plate is the highest, and the temperature of the DBCs at the four corners is slightly lower. The welding void rate of the DBCs at the four corners is significantly higher than that of the two DBCs at the center. The higher void rate seriously affects the Reliability of IGBT modules. Although prolonging the soldering time and increasing the soldering temperature may reduce the soldering void rate, there are still many problems such as low module reliability and low soldering efficiency.

[0037] Next, the specific technical solution of the present invention will be introduced in detail.

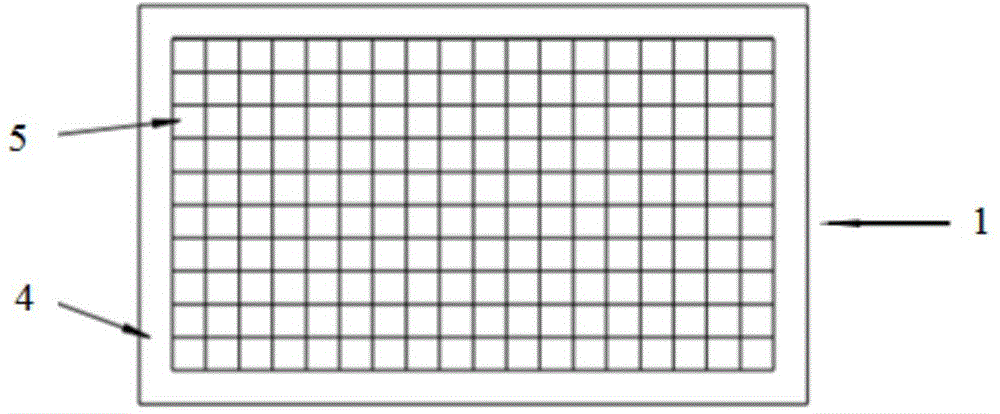

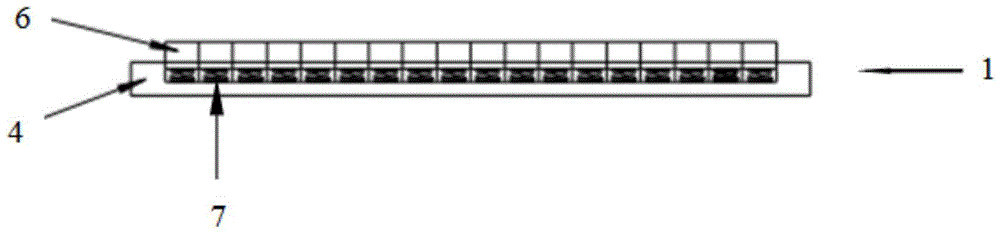

[0038] A heating plate 1, which is used in the welding of IGBT modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com