Ultrapure mixed gas preparation system and method

A preparation system and mixed gas technology, applied in the direction of mixing methods, chemical instruments and methods, mixers, etc., can solve the problems affecting the purity of ultra-pure mixed gas and the accuracy of gas distribution, the amount of raw material gas and the increase in time cost, etc. Achieve the effect of reducing impact, reducing consumption and time cost, and increasing air supply pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

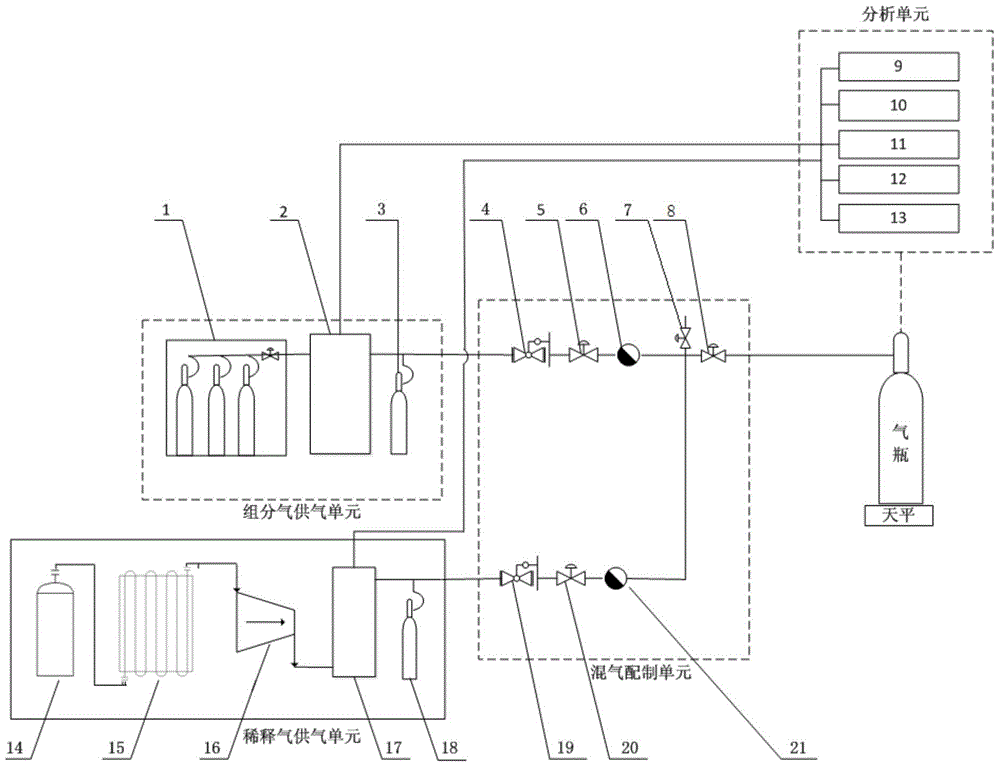

[0069] Such as figure 1 As shown, the ultra-pure mixed gas preparation system includes: container III 1, purifier III 2, buffer bottle III 3, pressure reducing valve I 4, diaphragm valve I 5, one-way valve I 6, vent port 7, and gas cylinder Filling pipeline 8, gas chromatograph with PDD detector 9, trace oxygen analyzer 10, trace water analyzer 11, particle counter 12, gas chromatograph with TCD detector 13, cryogenic liquid storage tank II 14, vaporizer II 15. Diaphragm compressor II 16, purifier II 17, buffer bottle II 18, pressure reducing valve II 19, diaphragm valve II 20, check valve II 21.

[0070] The connection relationship is: container III 1, purifier III 2, buffer bottle III 3, pressure reducing valve I 4, diaphragm valve I 5, check valve I 6 connected in sequence, cryogenic liquid storage tank II 14, vaporizer II 15 , diaphragm compressor II 16, purifier II 17, buffer bottle II 18, pressure reducing valve II 19, diaphragm valve II 20, and check valve II 21 are co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com