Core making process and core making device of triethylamine cold box

A core-making device and a technology of triethylamine, applied in the field of casting and molding, can solve the problems of unenvironmental protection, death, low production efficiency, etc., and achieve the effects of saving energy, saving the use of phosphoric acid, and saving the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

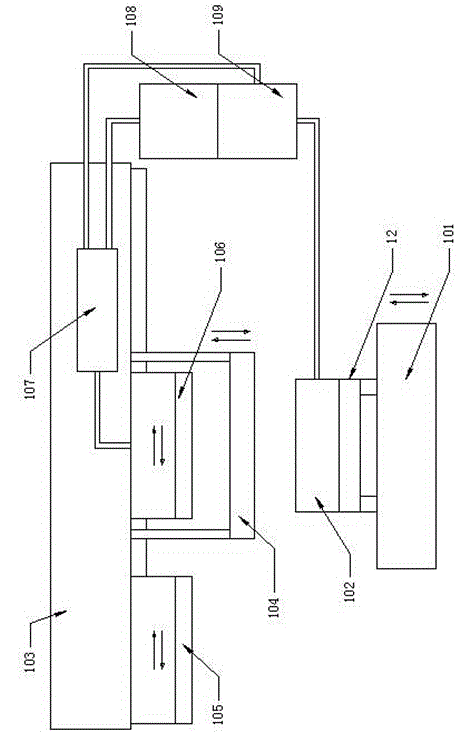

[0037] Embodiment one: see figure 1 , as shown in the legend therein, a triethylamine cold box core-making device is a lifting type core-making device, including a bottom bracket 101, a lower core box 102 set on the bottom bracket 101, a bottom The top support 103 above the support 101, the upper core box 104 installed on the top support 103, the sand shooting mechanism 105 and the blowing / core ejector mechanism 106 which are respectively installed on the top support 103 and positioned above the upper core box 104, The air mixing mechanism 107 communicated with the air blowing / top core mechanism 106, the triethylamine gas generating device 108 and the triethylamine mixed gas collecting and compressing device 109 respectively communicated with the gas mixing mechanism 107, and the triethylamine mixed gas collecting and compressing device 109 The inlet is communicated with the lower core box 102, and the sand shooting mechanism 105 is communicated with the sand mixing mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com