Method for preparing active iron oxide powder materials by means of vacuum aluminothermic reduction

A technology of oxide powder and active iron, which is applied in the field of material manufacturing, can solve the problems of complex preparation process, high cost, and no active iron oxide has been seen, and achieve the effects of simple process, low cost, good catalytic activity and magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1, using ferric oxide micron powder as raw material, weighing 1g ferric oxide; using aluminum micron powder as reducing agent, weighing 1g aluminum powder; mixing the raw material and reducing agent evenly, and setting aside;

[0036] Step 2. Place the mixture in step 1 in the center of a clean porcelain boat;

[0037] Step 3. Put the porcelain boat prepared in step 2 into the middle of the high-temperature tube furnace, seal the tube furnace, and use a vacuum pump to pump the air pressure inside the tube furnace into a negative pressure state, and maintain the vacuum degree at less than 5pa;

[0038] Step 4. Heat the tube furnace to 900° C. at a heating rate of 20 / min, maintain it for 6-12 hours, stop heating, and take out the reacted active iron oxide powder after the tube furnace cools down to room temperature.

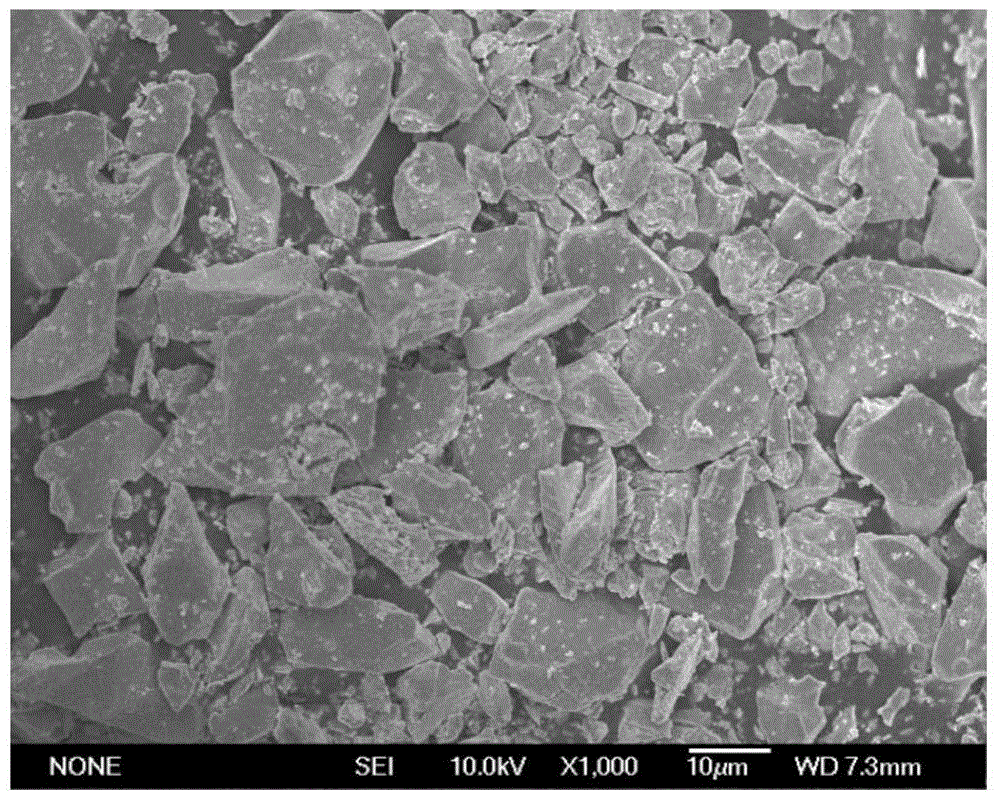

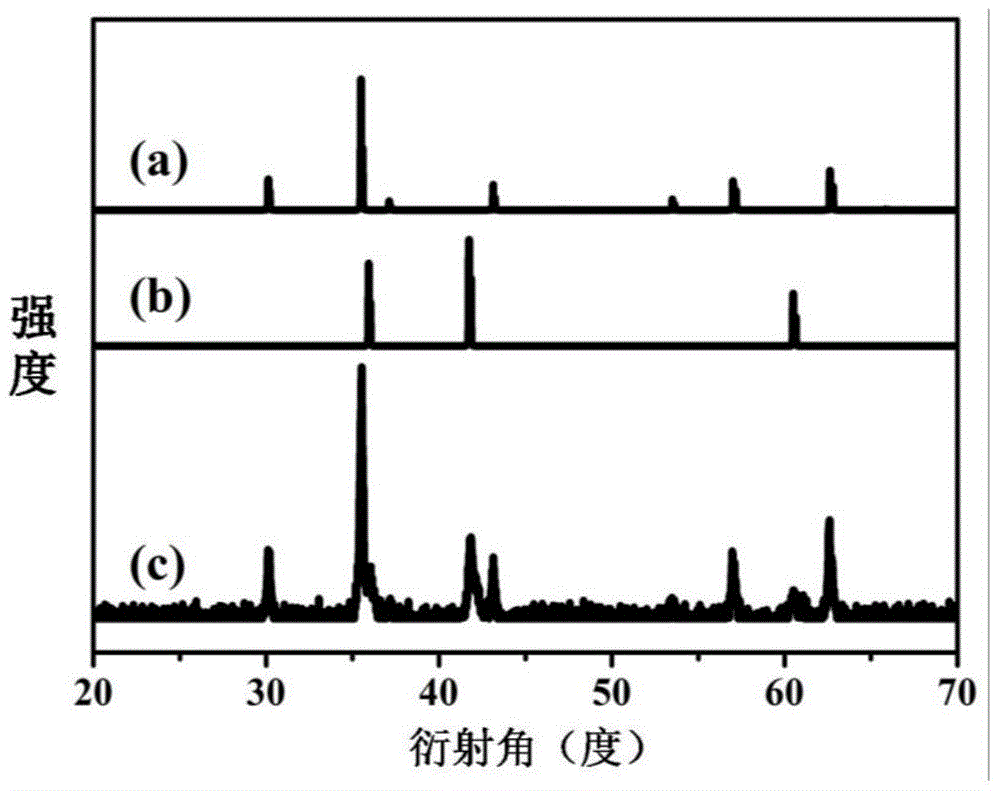

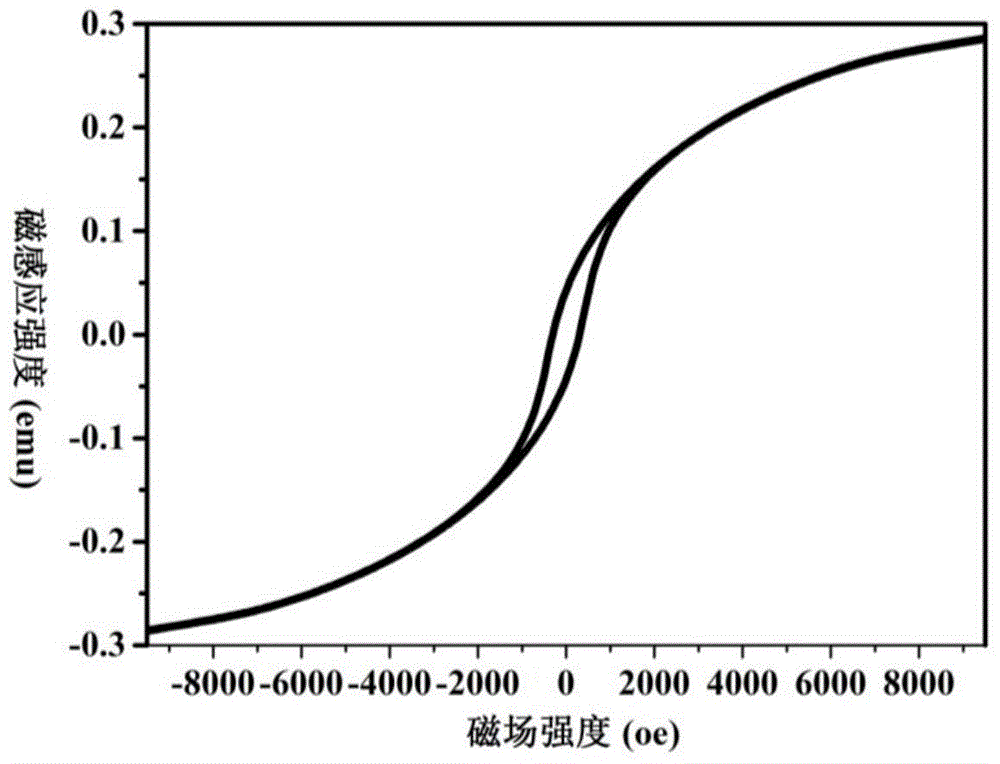

[0039] Step 5. Put the product obtained in step 4 into an agate mortar and grind for 5 minutes to obtain active FeO / Fe 3 o 4 Material. Sample FeO / Fe...

Embodiment 2

[0041] Step 1, using ferric oxide micron powder as raw material, weighing 1g ferric oxide; using aluminum micron powder as reducing agent, weighing 2g aluminum powder; mixing the raw material and reducing agent evenly, and setting aside;

[0042] Step 2. Place the mixture in step 1 in the center of a clean porcelain boat;

[0043] Step 3. Put the porcelain boat prepared in step 2 into the middle of the high-temperature tube furnace, seal the tube furnace, and use a vacuum pump to pump the air pressure inside the tube furnace into a negative pressure state, and maintain the vacuum degree at less than 5pa;

[0044] Step 4: Heat the tube furnace to 950 °C at a heating rate of 25 °C / min, maintain it for 9 hours, stop heating, and take out the reacted active iron oxide powder after the tube furnace cools down to room temperature.

[0045] Step 5. Put the product obtained in step 4 into an agate mortar and grind for 10 minutes to obtain the FeO material.

[0046] The sample FeO is ...

Embodiment 3

[0048] Step 1, using ferric oxide micron powder as a raw material, weighing 1g of ferric oxide; using aluminum micron powder as a reducing agent, weighing 5g aluminum powder; mixing the raw material and reducing agent evenly, and setting aside;

[0049] Step 2. Place the mixture in step 1 in the center of a clean porcelain boat;

[0050] Step 3. Put the porcelain boat prepared in step 2 into the middle of the high-temperature tube furnace, seal the tube furnace, and use a vacuum pump to pump the air pressure inside the tube furnace into a negative pressure state, and maintain the vacuum degree at less than 5pa;

[0051] Step 4: Heat the tube furnace to 1000 °C at a heating rate of 30 °C / min, maintain it for 12 hours, stop heating, and take out the reacted active iron oxide powder after the tube furnace cools down to room temperature.

[0052] Step 5. Put the product obtained in step 4 into an agate mortar and grind for 15 minutes to obtain Fe / FeO material.

[0053] The sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com