Waterproof breathable antibacterial type TPU (thermoplastic polyurethane) film and preparation method thereof

A waterproof, breathable and film technology, which is applied in the field of waterproof, breathable and antibacterial TPU film and its preparation, and can solve the problems of no improvement in the stability and failure of sterilizing and persistent bactericides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

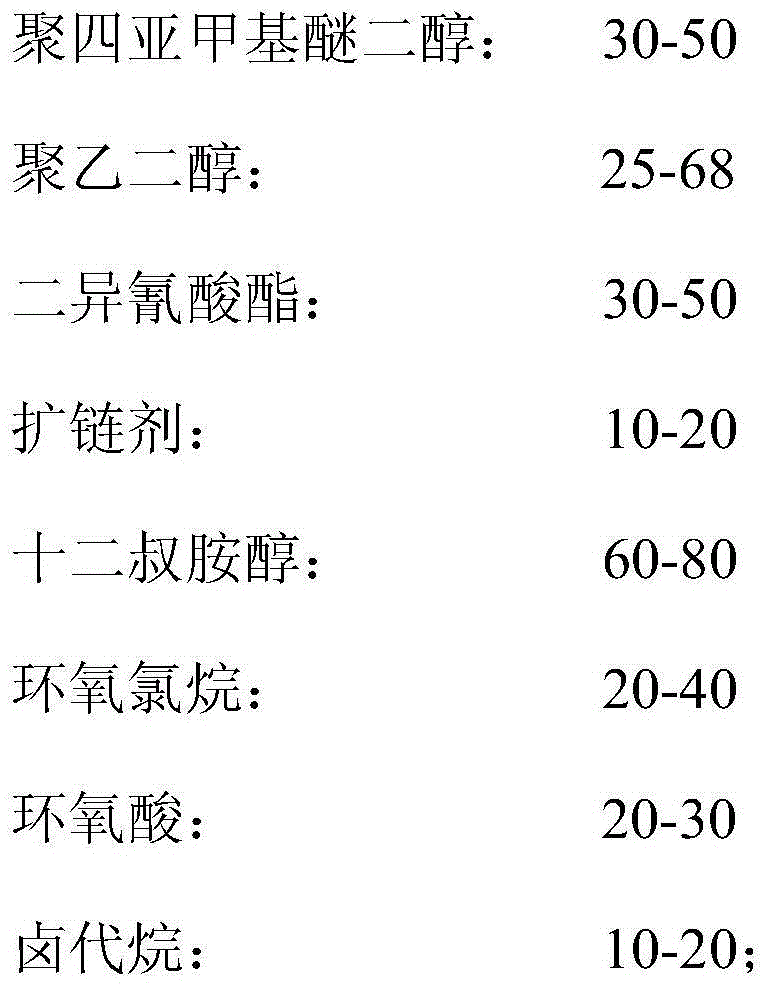

[0052] The raw material composition and parts by weight of the present embodiment are as follows:

[0053]

[0054] The raw materials in this embodiment also include catalyst, light stabilizer, heat stabilizer, anti-hydrolysis agent and lubricant;

[0055] The number average molecular weight of polyethylene glycol is 2000;

[0056] The present embodiment adopts following method to carry out the preparation of TPU film:

[0057] (1) Take a dry container, add polytetramethylene ether glycol, polyethylene glycol and tertiary lauryl amine alcohol and stir at a speed of 80r / min, heat to 80°C in a vacuum state, and dehydrate for 20min;

[0058] (2) Cool the reaction vessel to 40°C, add diisocyanate under the protection of helium, and carry out prepolymerization at 55°C for 15 minutes;

[0059] (3) drop chain extender, catalyst, light stabilizer, heat stabilizer, anti-hydrolysis agent and lubricant, carry out TPU synthetic reaction;

[0060] (4) Heating the reaction vessel to 7...

Embodiment 2

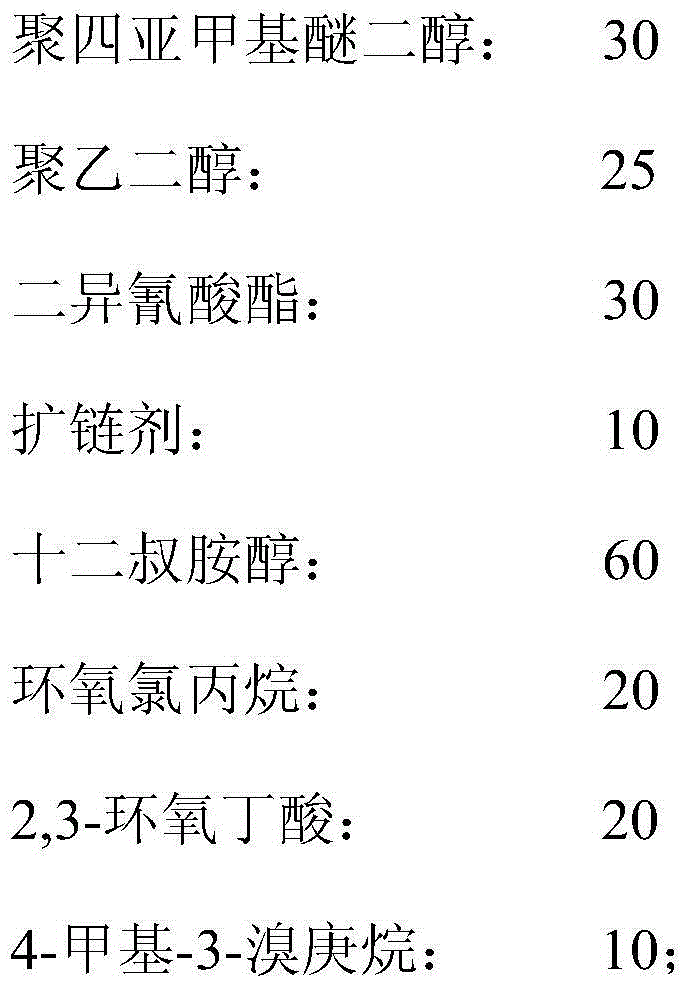

[0063] The raw material composition and parts by weight of the present embodiment are as follows:

[0064]

[0065] Raw materials in this embodiment also include catalyst, light stabilizer and thermal stabilizer;

[0066] The number average molecular weight of polyethylene glycol is 5000;

[0067] The present embodiment adopts following method to carry out the preparation of TPU film:

[0068] (1) Take a dry container, add polytetramethylene ether glycol, polyethylene glycol and tertiary lauryl amine alcohol and stir at a speed of 90r / min, heat to 80°C in a vacuum state, and dehydrate for 20min;

[0069] (2) Cool the reaction container to 40°C, add diisocyanate under the protection of neon gas, and carry out prepolymerization reaction at 55°C for 15 minutes;

[0070] (3) drop chain extender, catalyzer, light stabilizer and heat stabilizer, carry out TPU synthetic reaction;

[0071] (4) The temperature of the reaction vessel was raised to 70°C, and then epoxyheptachlorohy...

Embodiment 3

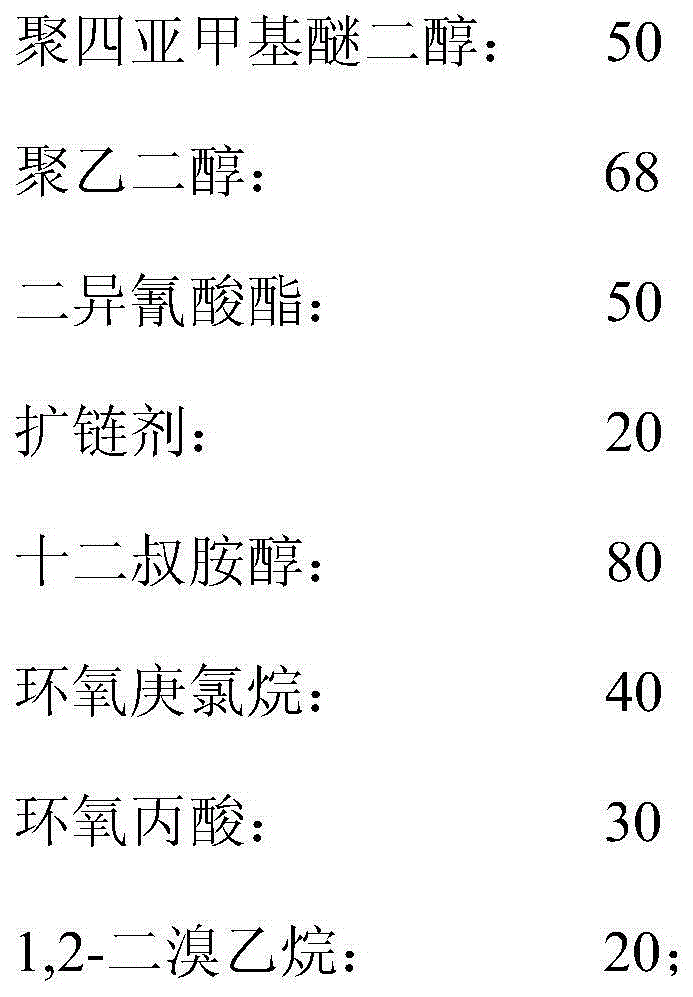

[0074] The raw material composition and parts by weight of the present embodiment are as follows:

[0075]

[0076] The raw material in the present embodiment also includes thermal stabilizer, anti-hydrolysis agent and lubricant;

[0077] The number average molecular weight of polyethylene glycol is 3500;

[0078] The present embodiment adopts following method to carry out the preparation of TPU film:

[0079] (1) Take a dry container, add polytetramethylene ether glycol, polyethylene glycol and tertiary lauryl amine alcohol and stir at a speed of 100r / min, heat to 80°C in a vacuum state, and dehydrate for 20min;

[0080] (2) Cool the reaction vessel to 40°C, add diisocyanate under the protection of helium, and carry out prepolymerization at 55°C for 15 minutes;

[0081] (3) drop chain extender, heat stabilizer, anti-hydrolysis agent and lubricant, carry out TPU synthetic reaction;

[0082] (4) Heating the temperature of the reaction vessel to 70°C, then adding epichlorohy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com