Processing method of rabbit hair

A processing method and technology of rabbit hair, applied in dyeing method, biochemical fiber treatment, textile and papermaking, etc., can solve the problem of destroying the integrity of the scales on the surface of rabbit hair fibers, reducing the natural color and feel of rabbit hair products, and having hidden dangers in safe production, etc. problem, to achieve the effect of superior durability, guarantee of spinnability, and improvement of quality and color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

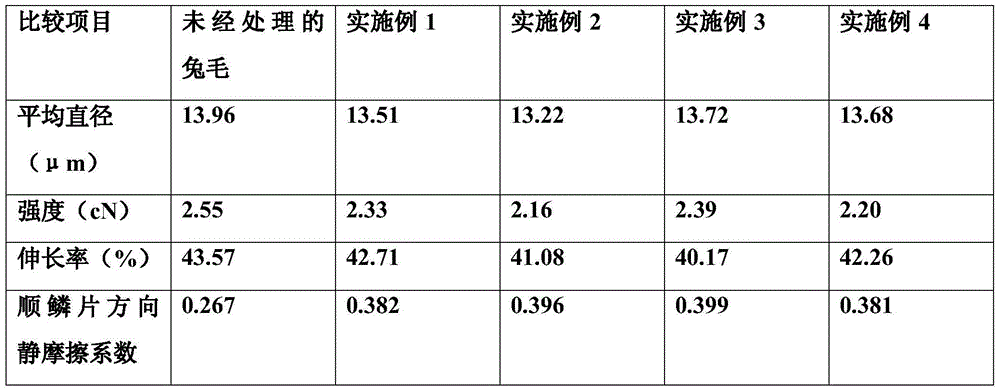

Examples

Embodiment 1

[0048] Combining, drafting and combing a plurality of rabbit hair fibers on a needle carding machine to obtain straight rabbit hair strips;

[0049] Then carry out oxidation treatment: immerse the rabbit hair strips in the ammonia water oxidation solution for 15 minutes at room temperature, wherein the ammonia water content is 50ml / L, and the bath ratio is 1:35;

[0050]After washing with water, perform enzyme treatment: add neutral protease 3-5.5% owf, enzyme treatment time 20 minutes, control temperature at 45°C, bath ratio 1:35, pH value between 6.5-7; the neutral protease is preferably It is savinase silk fibroin; after washing with water, carry out reduction treatment: use 5 parts by weight of sodium sulfite, 0.05 parts by weight of 1-dodecylazepan-2 ketone, and 150 parts by weight of water to make rabbit fur strips Immerse at room temperature for 20-30 minutes, bath ratio 1:33;

[0051] After washing with water, carry out dyeing treatment: configure the dyeing solution ...

Embodiment 2

[0055] Combining, drafting and combing a plurality of rabbit hair fibers on a needle carding machine to obtain straight rabbit hair strips;

[0056] Then carry out oxidation treatment: immerse the rabbit hair strips in the ammonia water oxidation solution at room temperature for 15-20 minutes, wherein the ammonia water content is 55ml / L, and the bath ratio is 1:37; and the ammonia water oxidation solution uses sodium borate as an addition compound, Sodium borate content is 4g / L;

[0057] After washing with water, perform enzyme treatment: add neutral protease 3-7% owf, enzyme treatment time 20-35 minutes, control temperature at 45-55°C, bath ratio 1:40, pH value between 6.5-7.5; Neutral protease is preferably neutral fibroin;

[0058] After washing with water, carry out reduction treatment: 6 parts by weight of sodium sulfite, 0.06 parts by weight of 1-dodecylazepan-2 ketone, and 200 parts by weight of water, soak the rabbit fur strips at normal temperature for 20-30 minutes...

Embodiment 3

[0063] Combining, drafting and combing a plurality of rabbit hair fibers on a needle carding machine to obtain straight rabbit hair strips;

[0064] Then carry out oxidation treatment: immerse the rabbit wool strips in the ammonia water oxidation solution at room temperature for 15 minutes, wherein the ammonia water content is 50ml / L, and the bath ratio is 1:35; sodium borate is used as the addition compound in the ammonia water oxidation solution, and the sodium borate content 3g / L;

[0065] After washing with water, perform enzyme treatment: add neutral protease 3% owf, enzyme treatment time is 20 minutes, control temperature at 45-55°C, bath ratio 1:35, pH value between 6.5-7.5; the neutral protease savinase Fibroin.

[0066] After washing with water, carry out reduction treatment: 5 parts by weight of sodium sulfite, 0.05 parts by weight of 1-dodecylazepan-2 ketone, and 150 parts by weight of water, soak the rabbit fur strips at normal temperature for 20-30 minutes, bath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com