Tube heating furnace low-calorific value fuel gas stable combustion method

A tubular heating furnace, stable combustion technology, applied in the direction of combustion method, combustion equipment, fuel supply, etc., to achieve the effects of high combustion intensity, simple process flow, and fuel saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

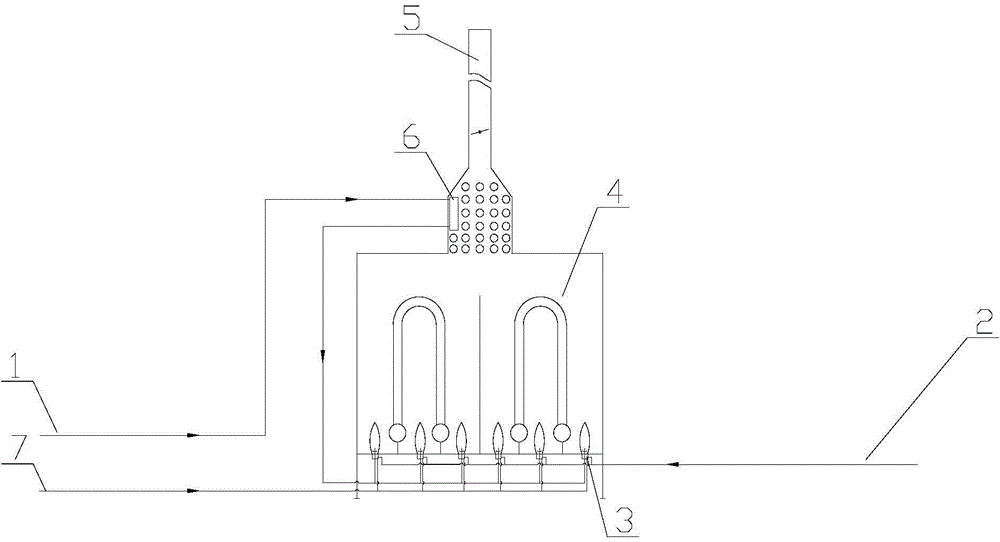

Embodiment 1

[0041] A new method for stable combustion of low calorific value fuel gas in tubular heating furnaces, the process is as follows figure 1 As shown, the combustion system of the tubular heating furnace is mainly composed of fuel gas and air. The fuel gas is divided into low calorific value fuel gas and auxiliary blended fuel gas. In the method of the present invention, the low calorific value fuel gas passes through the fuel gas low pressure drop preheater 6 enters the burner 3 after heating, the burner 3 is a dual-fuel burner, and the fuel gas low pressure drop preheater 6 is a turbulent heat exchanger, and then diffusion combustion occurs in the tubular heating furnace 4.

[0042]Low calorific value fuel gas is generally flexible coking gas, desorbed gas, various types of coal gas, etc. in refineries, and the temperature is generally room temperature. The low calorific value fuel gas first enters the fuel gas low-pressure drop preheater 6 through the main fuel gas pipeline 1,...

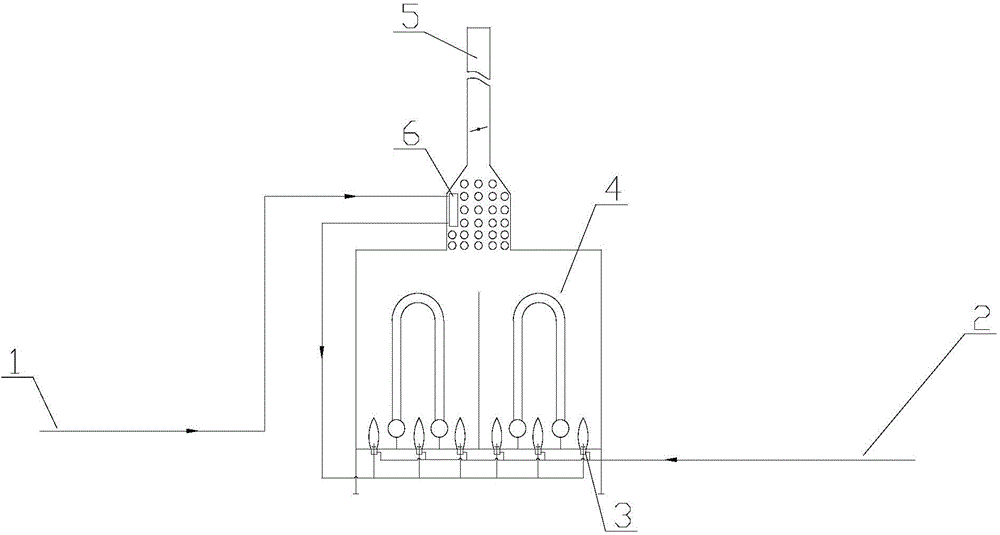

Embodiment 2

[0048] A new method for stable combustion of low calorific value fuel gas in tubular heating furnaces, the process is as follows figure 2 As shown, it is generally the same as that of Embodiment 1, except that the auxiliary blended fuel gas is not blended, and the auxiliary blended fuel gas pipeline 7 is not required, and only the low calorific value fuel gas is preheated by the fuel gas low-pressure drop preheater 6. Participate in diffusion combustion after being heated to 100-500°C. The burner adopts a conventional low-nitrogen oxide burner, and the fuel gas low pressure drop preheater 6 is a tubular heat exchanger.

[0049] When the low calorific value fuel gas is preheated for high-intensity combustion, on the one hand, the combustion of the low calorific value fuel gas can be stabilized, and on the other hand, the energy utilization rate of the low calorific value fuel can be increased by 2%-12%.

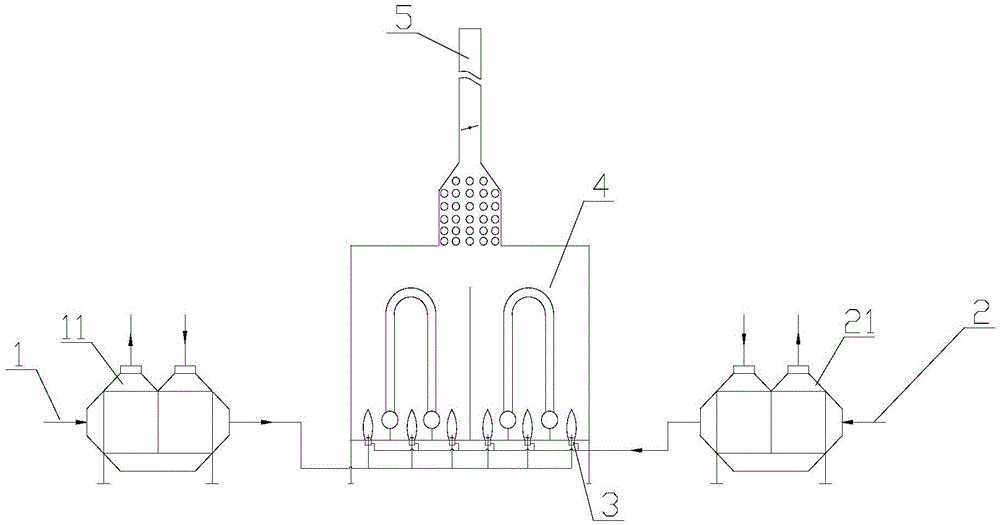

Embodiment 3

[0051] A new method for stable combustion of low calorific value fuel gas in tubular heating furnaces, the process is as follows image 3 As shown, it is generally the same as that of Example 1, except that the auxiliary blended fuel gas is not blended, the auxiliary blended fuel gas pipeline 7 is not required, and only the low calorific value fuel gas is preheated to 100- Participate in diffusion combustion after 500°C, while the combustion-supporting air is preheated to 100-500°C by the combustion-supporting air preheater 22, the burner 3 is a double preheating low-NOx burner, and the heat source of the combustion-supporting air preheater 22 can be multiple A heat source, such as high temperature flue gas or medium and low pressure steam.

[0052] When the low-calorific-value fuel gas and air are simultaneously preheated for high-intensity combustion, on the one hand, the combustion of the low-calorific-value fuel gas can be stabilized, and on the other hand, the energy util...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com